Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Electric Motor Rebuilder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Electric Motor Rebuilder so you can tailor your answers to impress potential employers.

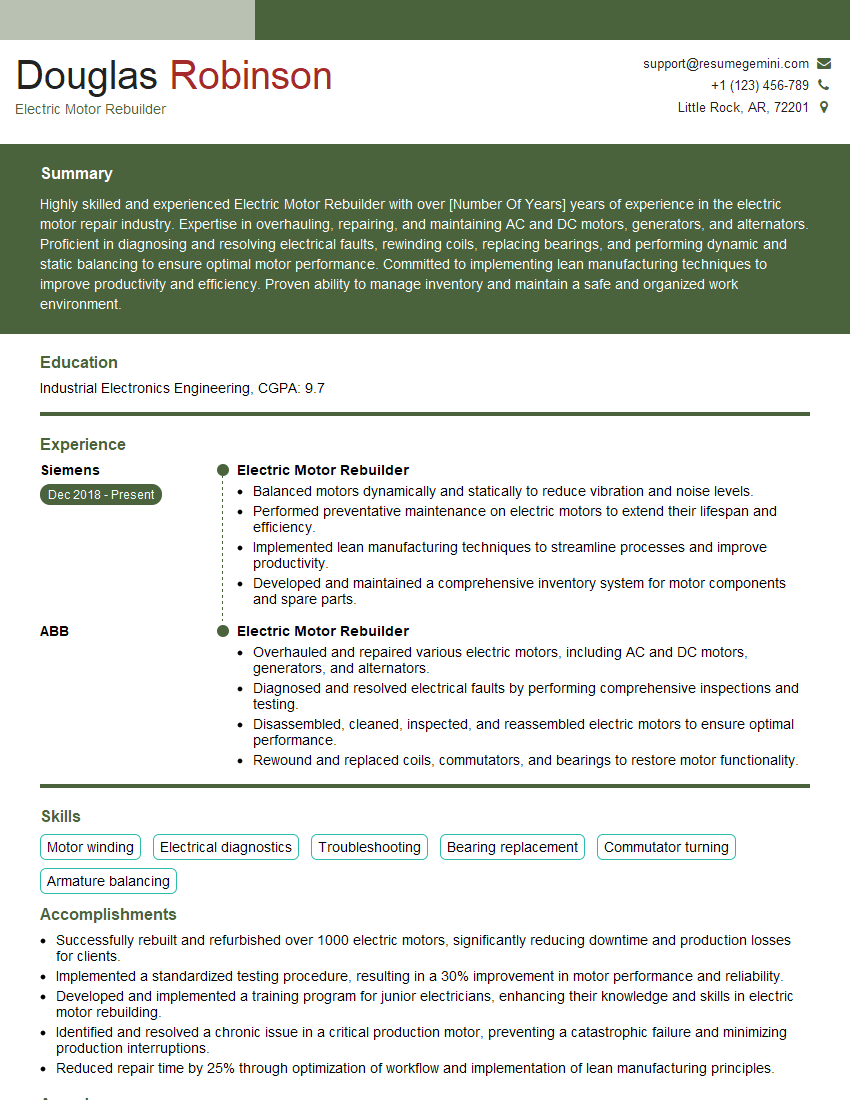

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Motor Rebuilder

1. How do you determine the root cause of a motor failure?

- Firstly, I collect the motor’s history, including its operating conditions, maintenance records, and any recent repairs.

- Next, I perform a visual inspection of the motor, looking for any obvious signs of damage, such as burned windings, broken shafts, or loose connections.

- I use a megger to test the insulation resistance of the motor’s windings.

- If the megger test indicates a problem, I use a growler to locate the shorted windings.

- Once I have identified the root cause of the failure, I can recommend the necessary repairs.

2. What are the different types of electric motors?

AC Motors

- Single-phase motors

- Three-phase motors

- Polyphase motors

DC Motors

- Series motors

- Shunt motors

- Compound motors

3. What is the difference between a synchronous motor and an asynchronous motor?

- Synchronous motors run at a constant speed, while asynchronous motors run at a slightly slower speed than their synchronous speed.

- The rotor of a synchronous motor is made of a permanent magnet, while the rotor of an asynchronous motor is made of a conducting material.

- Synchronous motors are more efficient than asynchronous motors, but they are also more expensive.

4. What is the purpose of a motor starter?

- To protect the motor from damage

- To control the speed of the motor

- To reverse the direction of the motor

5. What are the different types of motor starters?

- Manual motor starters

- Magnetic motor starters

- Solid-state motor starters

6. How do you troubleshoot a motor starter?

- Check the power supply to the motor starter.

- Check the control circuit for open or shorted wires.

- Check the contactor for burned or pitted contacts.

- Check the overload relay for a tripped condition.

7. What are the different types of motor bearings?

- Ball bearings

- Roller bearings

- Sleeve bearings

8. How do you lubricate motor bearings?

- Use the proper type of lubricant for the bearing.

- Apply the lubricant according to the manufacturer’s instructions.

- Do not over-lubricate the bearing.

9. What are the signs of a worn motor bearing?

- The motor is noisy

- The motor vibrates

- The motor runs hot

- The motor has a decreased output torque

10. How do you replace a motor bearing?

- Remove the motor from its mounting.

- Remove the end bells from the motor.

- Remove the old bearing from the motor shaft.

- Install the new bearing on the motor shaft.

- Reinstall the end bells on the motor.

- Reinstall the motor on its mounting.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Motor Rebuilder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Motor Rebuilder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Motor Rebuilders are responsible for repairing and rebuilding electric motors, ensuring optimal performance and extending their lifespan. Their key responsibilities include:

1. Diagnostics and Troubleshooting

Analyze electrical motors to identify malfunctions, assess damage, and determine the root cause of issues.

- Conduct electrical tests, including insulation resistance, continuity, and winding resistance measurements.

- Inspect mechanical components for wear, tear, or misalignment.

2. Disassembly and Repair

Safely disassemble motors to access and repair damaged or worn components.

- Replace faulty windings, bearings, brushes, and other components.

- Rebuild armatures, stators, rotors, and other motor parts.

3. Reassembly and Testing

Reassemble motors after repairs, ensuring proper alignment and fit.

- Perform final electrical tests to ensure the motor meets performance specifications.

- Balance rotors to minimize vibration.

4. Preventive Maintenance

Conduct preventive maintenance on motors to extend their lifespan and prevent breakdowns.

- Monitor motor performance and schedule regular maintenance based on usage.

- Clean and lubricate motors, inspect for early signs of wear, and replace worn parts.

Interview Tips

To ace an interview for an Electric Motor Rebuilder position, candidates should prepare thoroughly and demonstrate their skills and qualifications. Here are some tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products, and services. Research the specific role and its responsibilities to tailor your answers accordingly.

- Visit the company’s website, read industry publications, and talk to people in the field.

- Review the job description carefully and highlight your relevant skills and experience.

2. Highlight Technical Skills

Showcase your expertise in electric motor repair and maintenance. Quantify your accomplishments and provide specific examples of your work.

- Discuss your experience in diagnosing and repairing various types of electric motors.

- Explain your knowledge of motor components, winding techniques, and testing procedures.

3. Emphasize Attention to Detail

Electric Motor Rebuilders require meticulous attention to detail to ensure motors are repaired precisely and safely. Highlight your ability to follow instructions carefully and maintain high standards.

- Provide examples of your troubleshooting and repair work that demonstrate your thoroughness.

- Explain your commitment to quality control and safety protocols.

4. Practice Problem-Solving

Interviews often involve problem-solving questions to assess your critical thinking and troubleshooting abilities. Prepare for these questions by practicing with scenarios related to electric motor repair.

- Think through different types of motor malfunctions and explain how you would approach them.

- Consider examples of troubleshooting challenges you have faced and how you resolved them.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Motor Rebuilder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!