Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electric Motor Repairman position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

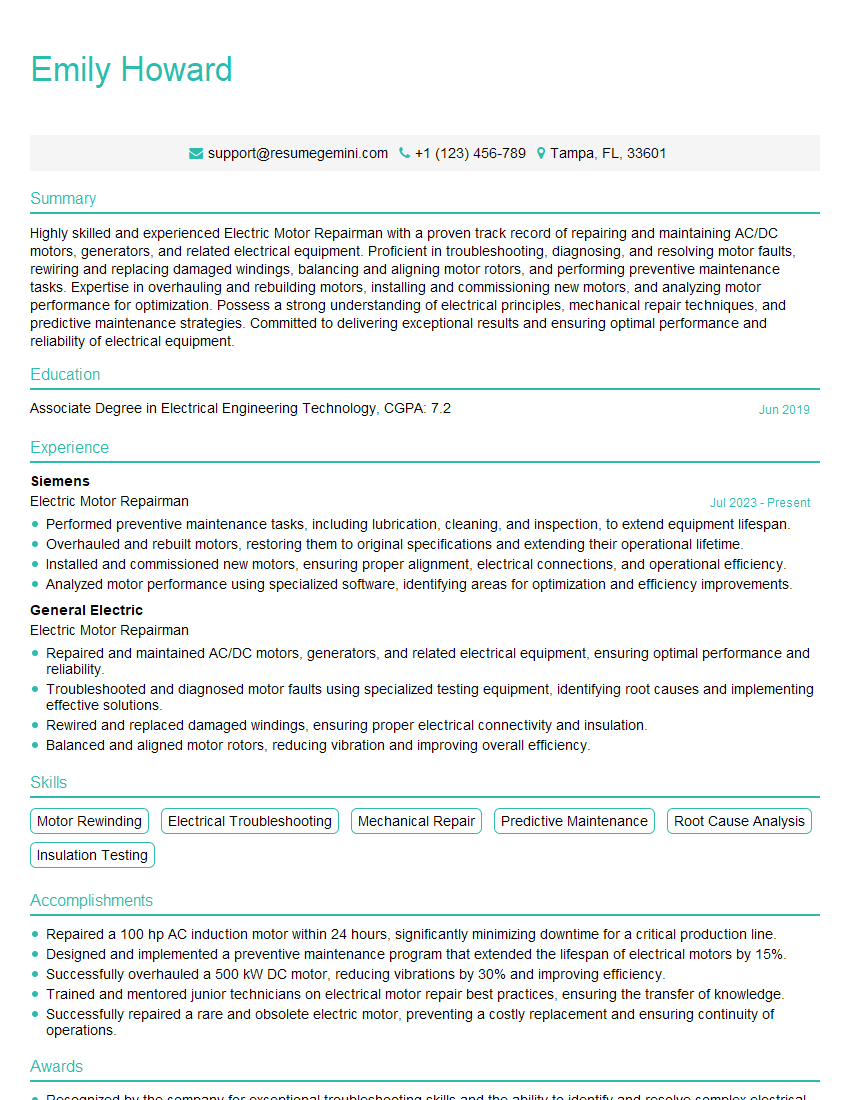

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Motor Repairman

1. What are the different types of electric motors and their applications?

There are various types of electric motors, each with specific characteristics and applications. Here are a few common types:

- DC Motors: Convert direct current (DC) into mechanical energy. Used in applications requiring variable speed control, such as electric vehicles and power tools.

- AC Motors: Convert alternating current (AC) into mechanical energy. Commonly used in industrial machinery, appliances, and power generation.

- Induction Motors: A type of AC motor that operates based on the principle of electromagnetic induction. Widely used in industrial applications due to their ruggedness and reliability.

- Synchronous Motors: Another type of AC motor that operates in synchrony with the AC power supply. Used in applications requiring precise speed control, such as generators and clocks.

- Stepper Motors: Used in applications requiring precise angular positioning, such as CNC machines and robotics.

2. Describe the steps involved in troubleshooting an electric motor.

Testing for Power and Continuity

- Ensure the motor is disconnected from the power source.

- Check for power at the input terminals using a voltmeter.

- Use an ohmmeter to test for continuity in the motor windings and connections.

Inspecting the Motor

- Examine the motor housing for any visible damage or loose components.

- Check the bearings for excessive play or noise.

- Inspect the commutator or slip rings for wear or damage.

Testing Under Load

- Connect the motor to a load and run it at different speeds.

- Monitor the motor’s current draw, temperature, and vibration levels.

- Compare the results with known specifications or data from a similar motor.

3. How do you determine the efficiency of an electric motor?

The efficiency of an electric motor is determined by comparing its output power to its input power. Here’s how it’s calculated:

- Measure the motor’s output power: Use a dynamometer or measure the mechanical load and its speed.

- Measure the motor’s input power: Use a wattmeter to measure the voltage and current supplied to the motor.

- Calculate the efficiency: Divide the output power by the input power and multiply by 100 to express it as a percentage.

4. Explain the difference between a synchronous and an asynchronous motor.

- Synchronous Motor: Operates in synchrony with the AC power supply frequency. The rotor speed is directly proportional to the supply frequency.

- Asynchronous Motor: Also known as an induction motor, it operates at a speed slightly below the synchronous speed. The slip, or difference between synchronous and actual speed, depends on the load.

5. Describe the purpose of a starter in an electric motor.

- Reduces Starting Current: Limits the high current drawn by the motor during startup.

- Gradual Acceleration: Gradually increases the voltage applied to the motor, allowing it to accelerate smoothly.

- Protection: Protects the motor from excessive current draw and overheating during startup.

6. Explain the function of a centrifugal switch in an electric motor.

- Starter Circuit Disconnect: When the motor reaches a certain speed, the centrifugal switch opens, disconnecting the starting circuit.

- Full Voltage Operation: Once disconnected, the motor runs at full voltage, improving efficiency.

7. What is the importance of proper lubrication for electric motors?

- Reduces Friction: Lubrication creates a film between moving parts, reducing friction and wear.

- Heat Dissipation: Lubricants help transfer heat away from bearings and other components, preventing overheating.

- Prevents Rust and Corrosion: Lubricants protect metal surfaces from rust and corrosion.

- Extends Motor Life: Proper lubrication significantly extends the lifespan of electric motors.

8. Describe the different types of bearings used in electric motors and their applications.

- Sleeve Bearings: Simple and inexpensive, used in low-speed and low-load applications.

- Ball Bearings: Used in medium-speed and medium-load applications, provide low friction and high efficiency.

- Roller Bearings: Designed for heavy-load applications, can withstand high axial and radial loads.

- Thrust Bearings: Specialized bearings used to handle axial loads, such as in vertical motors.

9. What are the common causes of overheating in electric motors?

- Overloading

- Poor ventilation

- Inadequate lubrication

- Bearing failure

- Electrical faults

- Environmental factors (dust, moisture)

10. What safety precautions should be taken when working on electric motors?

- Disconnect the power source: Always disconnect the motor from the power supply before performing any work.

- Ground the motor: Ground the motor frame to prevent electrical shock.

- Use insulated tools: Use tools with insulated handles to avoid electrical hazards.

- Wear appropriate PPE: Wear safety glasses, gloves, and other appropriate personal protective equipment.

- Follow manufacturer’s instructions: Refer to the manufacturer’s instructions for safe handling and maintenance procedures.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Motor Repairman.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Motor Repairman‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Motor Repairmen are responsible for repairing and maintaining electric motors and generators. They must have a thorough understanding of how electric motors work, as well as the ability to diagnose and repair problems. Some of their key responsibilities include:

1. Troubleshooting and repairing electric motors

Electric Motor Repairmen must be able to troubleshoot and repair a variety of electric motors, including AC and DC motors, single-phase and three-phase motors, and fractional horsepower and large horsepower motors. They must be able to identify the cause of the problem and make the necessary repairs to get the motor up and running again.

- Inspecting and testing electric motors to identify problems

- Disassembling and reassembling electric motors

- Replacing worn or damaged parts

- Rewinding electric motors

- Testing and adjusting electric motors to ensure proper operation

2. Maintaining electric motors

Electric Motor Repairmen must also be able to maintain electric motors to prevent problems from occurring. This includes tasks such as:

- Lubricating electric motors

- Cleaning and inspecting electric motors

- Replacing worn or damaged parts

- Performing preventative maintenance tasks

3. Installing and wiring electric motors

Electric Motor Repairmen may also be responsible for installing and wiring electric motors. This includes tasks such as:

- Mounting electric motors

- Wiring electric motors

- Connecting electric motors to power sources

- Testing and adjusting electric motors to ensure proper operation

4. Safety

Electric Motor Repairmen must always follow safety procedures when working with electricity. This includes wearing appropriate safety gear, such as gloves and safety glasses, and following lockout/tagout procedures.

Interview Tips

To ace an interview for an Electric Motor Repairman position, it is important to be prepared. Here are a few tips:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and what they are looking for in a candidate. You can find information about the company on their website, social media pages, and Glassdoor.

- Know the company’s history, mission, and values.

- Learn about the specific job duties and responsibilities.

- Find out what qualifications the company is looking for in a candidate.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and concisely.

- Use the STAR method to answer interview questions.

- Be specific and provide examples from your experience.

- Quantify your accomplishments whenever possible.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as an Electric Motor Repairman. Be prepared to discuss your experience in detail, including the types of motors you have worked on, the repairs you have made, and the maintenance tasks you have performed.

- Highlight your experience and skills that are most relevant to the position.

- Use keywords from the job description in your answers.

- Be enthusiastic and positive when talking about your experience.

4. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are taking the interview seriously. Some good questions to ask include:

- What is the biggest challenge facing the company right now?

- What are the company’s goals for the next year?

- What is the company culture like?

- What is the next step in the interview process?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Motor Repairman interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.