Feeling lost in a sea of interview questions? Landed that dream interview for Electric Motor Winder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Electric Motor Winder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

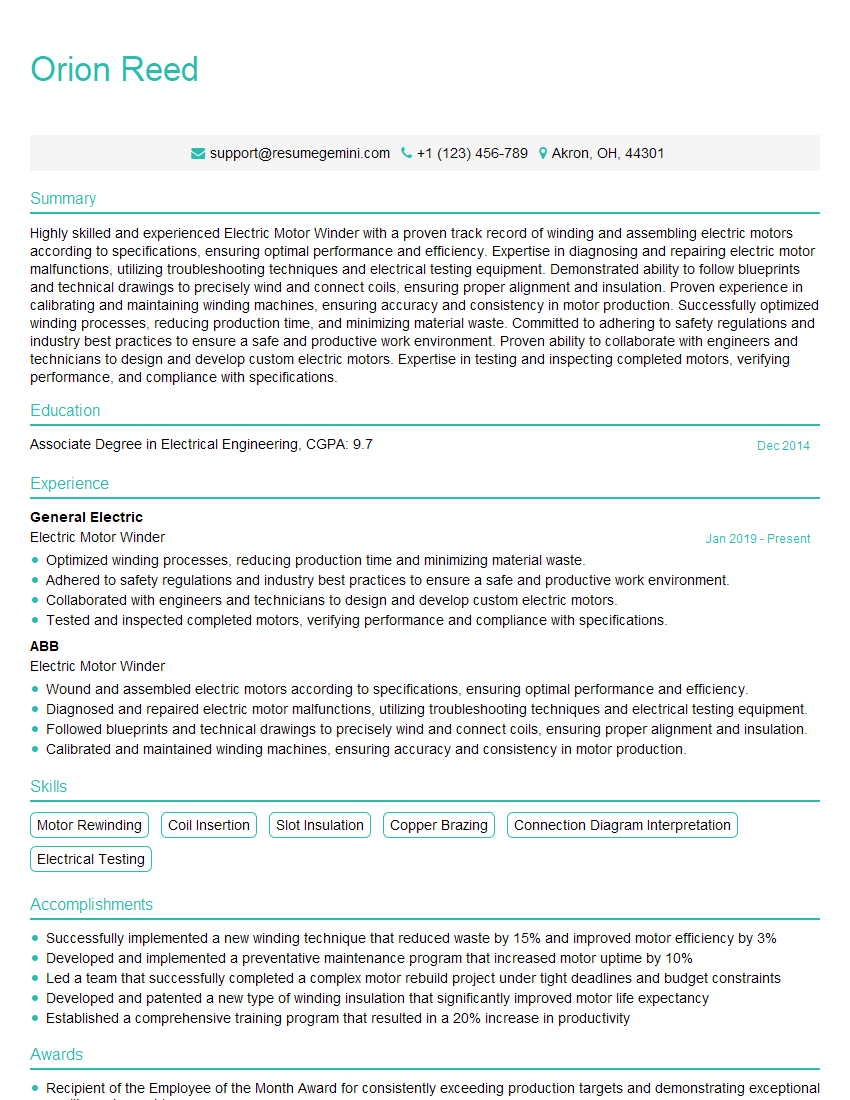

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Motor Winder

1. How do you determine the correct wire gauge for an electric motor winding?

To determine the correct wire gauge for an electric motor winding, I consider several factors:

- Current rating: The wire gauge must be able to carry the rated current of the motor without overheating.

- Voltage drop: The wire gauge must minimize voltage drop between the power source and the motor terminals.

- Coil resistance: The wire gauge affects the resistance of the motor coils, which influences the motor’s starting torque and speed.

- Space constraints: The wire gauge must fit within the available space in the motor’s slots and windings.

- Insulation rating: The wire gauge must be insulated to withstand the voltage and temperature conditions of the motor’s operation.

2. Explain the importance of proper insulation in electric motor windings.

Mechanical protection:

- Insulation protects the wire conductors from abrasion, moisture, and other environmental factors.

Electrical isolation:

- Insulation prevents electrical breakdown between conductors, coils, and the motor frame.

- It ensures that the motor operates safely and efficiently.

Temperature resistance:

- Insulation materials must withstand the heat generated by the motor’s operation without melting or degrading.

3. Describe the steps involved in preparing a motor stator for winding.

Preparing a motor stator for winding involves the following steps:

- Cleaning: Remove any dirt, grease, or debris from the stator core.

- Drying: If the stator has been exposed to moisture, it must be dried thoroughly to prevent insulation breakdown.

- Insulating: Apply insulating materials, such as varnish or epoxy, to the stator slots and windings to prevent electrical shorts.

- Inspecting: Carefully inspect the stator for any defects or damage before winding.

4. What types of winding patterns are commonly used in electric motor stators?

Common winding patterns used in electric motor stators include:

- Lap winding: Simple and efficient, used in low-voltage motors.

- Wave winding: Produces a smoother torque output, suitable for high-voltage motors.

- Distributed winding: Distributes the coils around the stator, reducing magnetic noise and vibration.

- Fractional-slot winding: Uses a non-integer number of slots per pole, reducing torque ripple.

5. Explain the function of a commutator in a DC motor.

In a DC motor, the commutator:

- Reverses the direction of current flow in the motor’s armature: This creates a continuous rotating motion.

- Reduces sparking: By interrupting the current flow at the correct moments.

6. What are the different methods for impregnating electric motor windings?

Methods for impregnating electric motor windings include:

- Vacuum-pressure impregnation (VPI): Uses a vacuum to remove air from the windings, then applies pressure to force in the impregnating resin.

- Dipping: The windings are dipped into the impregnating resin and then allowed to drain.

- Casting: The impregnating resin is poured into the windings and allowed to cure.

7. What are the safety precautions that must be taken when working with electric motors?

Safety precautions when working with electric motors include:

- Lockout/tagout: Ensure the motor is isolated from power before working on it.

- Personal protective equipment (PPE): Wear gloves, safety glasses, and proper clothing.

- Avoid contact with moving parts: Keep hands and loose clothing away from rotating shafts and belts.

- Test for voltage: Verify that the motor is not energized before touching any wires or terminals.

- Be aware of potential hazards: Such as heat, noise, and vibration.

8. What are the common causes of electric motor failure?

Common causes of electric motor failure include:

- Bearing failure: Worn or damaged bearings can cause excessive vibration and heat.

- Insulation breakdown: Aging, moisture, or excess heat can damage the insulation, leading to electrical shorts.

- Overheating: Overloading, poor ventilation, or excessive friction can cause the motor to overheat.

- Winding faults: Opens or shorts in the windings can disrupt the flow of current.

- External factors: Harsh environments, improper installation, or mechanical damage can contribute to motor failure.

9. Describe the process of troubleshooting an electric motor that is not running.

- Check for power: Verify that the motor is receiving power from the power source.

- Inspect the wiring: Look for loose connections, damaged wires, or open circuits.

- Test the bearings: Listen for unusual noises or vibrations, and check for excessive play in the shaft.

- Check the insulation: Use a multimeter to test for continuity in the windings and insulation.

- Check the commutator (DC motors): Inspect for wear, pitting, or damage, and ensure proper contact with the brushes.

10. What are your strengths and weaknesses as an Electric Motor Winder?

Strengths:

- Proficient in winding stators and rotors for various types of electric motors.

- Expertise in using precision winding machines and hand tools.

- Strong understanding of electrical theory and winding techniques.

- Meticulous attention to detail and quality.

- Ability to work independently and as part of a team.

Weaknesses:

- Limited experience with high-voltage motor winding.

- Need to improve efficiency in certain aspects of the winding process.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Motor Winder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Motor Winder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Electric Motor Winder, you will perform a range of crucial tasks to ensure the repair and maintenance of electric motors.

1. Motor Inspection and Assessment

You will be responsible for carefully inspecting and assessing electric motors to identify any potential issues or areas that require attention.

- Conduct comprehensive inspections, including visual examinations and performance evaluations, to determine the health and functionality of electric motors.

- Identify and document any faulty components or issues that may be causing malfunctions or reduced performance.

2. Motor Disassembly and Rewinding

You will disassemble and rewind motors as needed, ensuring precision and attention to detail throughout the process.

- Disassemble electric motors safely and efficiently, following established procedures and using appropriate tools.

- Rewind motor coils according to specifications, using specialized winding machines and techniques.

3. Component Repair and Replacement

You will perform necessary repairs and replacements of motor components to restore their functionality and performance.

- Repair or replace faulty motor components, such as bearings, brushes, and capacitors.

- Ensure the correct installation and alignment of components to restore proper motor operation.

4. Motor Reassembly and Testing

You will reassemble and test electric motors to ensure they meet specifications and perform as intended.

- Reassemble electric motors, following established guidelines and ensuring proper alignment and fit.

- Conduct testing to verify the functionality and performance of repaired or rewound motors.

Interview Tips

To ace your interview for an Electric Motor Winder position, consider the following tips:

1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and services. Research the specific role and its responsibilities to demonstrate your understanding and interest in the position.

- Visit the company’s website and social media pages to gather information about their business and culture.

- Thoroughly review the job description to understand the key responsibilities and qualifications required.

2. Highlight Your Skills and Experience

Emphasize your technical skills and experience in electric motor winding and repair. Highlight any relevant certifications or training you have completed.

- Quantify your accomplishments and provide specific examples of projects or tasks where you demonstrated your expertise.

- If you have experience working with specific types of electric motors or industries, be sure to mention it.

3. Prepare for Technical Questions

Anticipate questions related to electric motor theory, repair techniques, and industry standards. Practice answering these questions clearly and concisely.

- Review basic electrical principles and the different types of electric motors.

- Practice explaining common motor winding techniques and testing procedures.

4. Demonstrate Your Attention to Detail

Electric motor winding requires precision and attention to detail. Emphasize your ability to work meticulously and follow instructions carefully.

- Provide examples where you have successfully resolved complex technical issues.

- Be prepared to explain your quality control processes and how you ensure accuracy in your work.

5. Be Enthusiastic and Professional

Convey your enthusiasm for the field and your commitment to delivering high-quality work. Maintain a professional demeanor throughout the interview.

- Express your passion for electric motor winding and how it aligns with your career goals.

- Dress appropriately and arrive on time for the interview.

Next Step:

Now that you’re armed with the knowledge of Electric Motor Winder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Electric Motor Winder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini