Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Electric Plater interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Electric Plater so you can tailor your answers to impress potential employers.

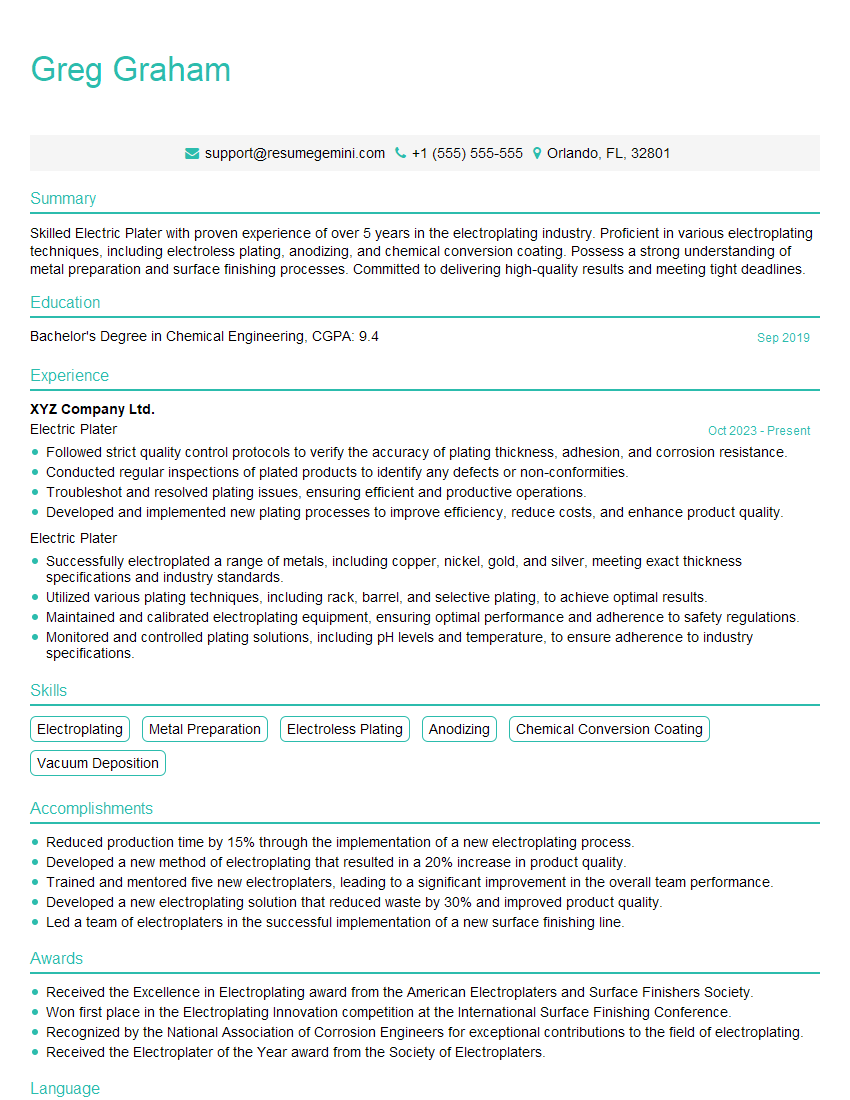

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Plater

1. Explain the process of electroplating?

Electroplating is the process of coating a metal surface with a thin layer of another metal by using an electric current. The process involves the following steps:

- Cleaning the surface of the metal to be plated

- Applying a thin layer of the plating metal to the surface

- Passing an electric current through the metal, which causes the plating metal to adhere to the surface

2. What are the different types of electroplating?

- Chrome plating

- Nickel plating

- Zinc plating

- Copper plating

3. What are the advantages of electroplating?

- Improved corrosion resistance

- Increased wear resistance

- Improved electrical conductivity

- Enhanced appearance

4. What are the disadvantages of electroplating?

- Can be expensive

- Can be time-consuming

- Can be difficult to control the thickness of the plating

5. What are the different types of plating baths?

- Acid baths

- Alkaline baths

- Neutral baths

6. What are the different types of plating anodes?

- Soluble anodes

- Insoluble anodes

7. What are the different types of plating currents?

- Direct current

- Alternating current

8. What are the different types of plating equipment?

- Plating tanks

- Plating racks

- Plating power supplies

9. What are the different types of plating defects?

- Blisters

- Peeling

- Cracking

- Discoloration

10. What are the different types of plating safety precautions?

- Wear proper protective clothing

- Use proper ventilation

- Handle chemicals safely

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Plater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Plater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of Electric Plater

Electric Platers are responsible for applying a thin layer of metal to the surface of a substrate, typically using an electrolytic process. They work in a variety of industries, including manufacturing, automotive, and electronics.

1. Prepare the Substrate

Before plating, the surface of the substrate must be prepared to ensure a good bond between the metal and the substrate. This may involve cleaning, degreasing, and etching the surface.

2. Set Up and Operate the Electroplating Equipment

Electric Platers set up and operate the electroplating equipment, which includes the plating tank, power supply, and other equipment. They adjust the parameters of the plating process, such as the temperature, voltage, and current, to achieve the desired results.

3. Monitor the Electroplating Process

Electric Platers monitor the electroplating process to ensure that it is proceeding correctly. They check the temperature, voltage, and current, and make adjustments as needed. They also inspect the plated surface for defects.

4. Remove the Plated Parts

Once the plating process is complete, the Electric Plater removes the plated parts from the plating tank. They may also perform post-plating operations, such as drying, polishing, or buffing the parts.

Interview Tips for Electric Platers

Preparing for an interview for an Electric Plater position can be daunting, but by following these tips, you can increase your chances of success.

1. Research the Company and the Position

Before your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and the specific requirements of the job.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that Electric Platers are likely to be asked. Practice answering these questions in advance so that you can deliver confident and well-thought-out responses.

Some common interview questions for Electric Platers include:

- Tell me about your experience with electroplating.

- What are your strengths and weaknesses as an Electric Plater?

- What are your career goals?

- Why are you interested in this position?

- What can you bring to this company?

3. Be Prepared to Discuss Your Experience

In your interview, be prepared to discuss your experience in detail. Highlight your skills and experience that are relevant to the position you are applying for.

For example, you might discuss your experience with:

- Preparing and plating different types of substrates

- Setting up and operating electroplating equipment

- Monitoring and troubleshooting the electroplating process

- Removing and post-processing plated parts

4. Ask Questions

At the end of your interview, be sure to ask the interviewer questions about the position and the company. This shows that you are interested in the position and that you are eager to learn more about the company.

Some good questions to ask include:

- What are the biggest challenges facing the company right now?

- What are the company’s goals for the future?

- What is the company culture like?

- What are the opportunities for advancement within the company?

- What is the next step in the interview process?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Plater interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!