Are you gearing up for an interview for a Electric Sealing Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Electric Sealing Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

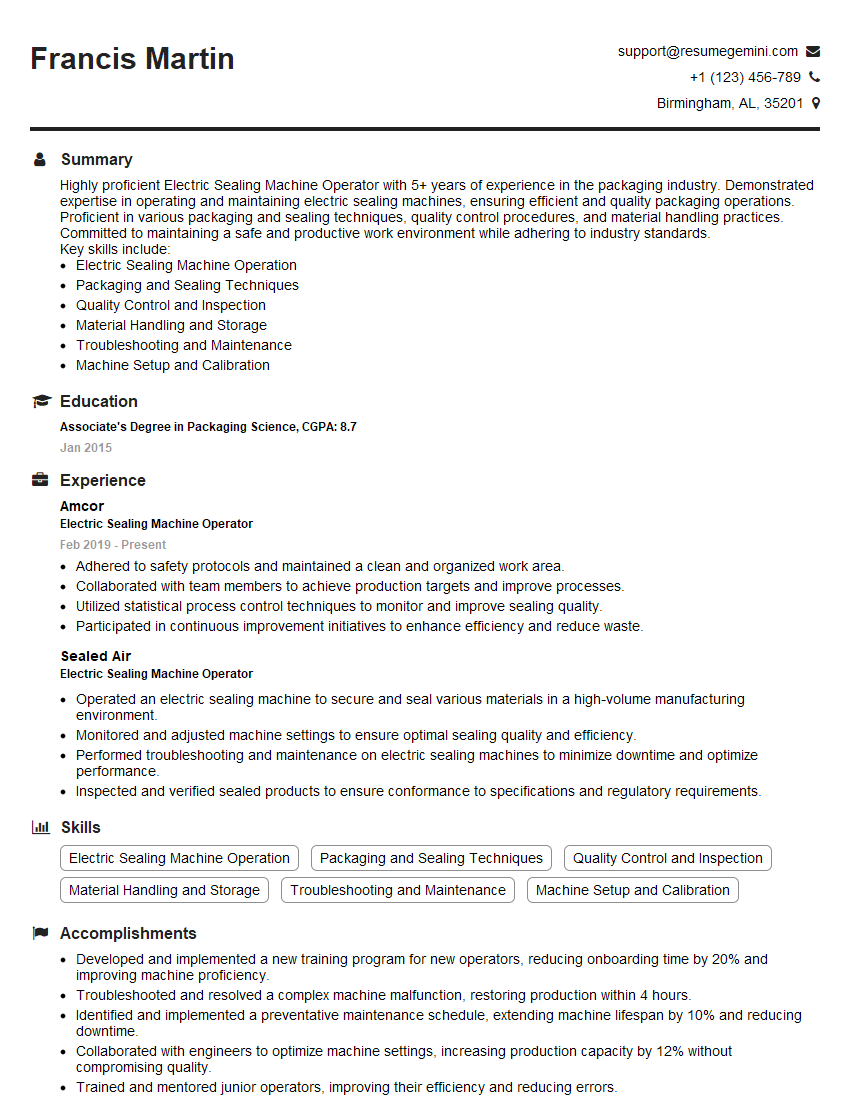

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Sealing Machine Operator

1. What are the major responsibilities of an Electric Sealing Machine Operator?

As an Electric Sealing Machine Operator, my key responsibilities include:

- Setting up and operating electric sealing machines to seal various types of packaging materials.

- Monitoring the sealing process to ensure optimal seal quality and package integrity.

- Maintaining and troubleshooting sealing machines to ensure smooth operation and prevent downtime.

- Inspecting sealed packages to verify seal integrity and overall quality.

- Adhering to established quality and safety protocols to ensure the production of high-quality sealed products.

2. How do you ensure that the sealing process meets the required standards?

Monitoring Seal Quality

- Regularly inspecting sealed packages for proper seal formation, strength, and leak tightness.

- Using testing equipment or gauges to measure seal strength and integrity.

Calibration and Maintenance

- Performing routine calibration of sealing machines to maintain accurate temperature and pressure settings.

- Conducting preventive maintenance tasks, such as cleaning, lubrication, and replacement of worn parts, to ensure optimal machine performance.

3. How do you handle troubleshooting and repairs of electric sealing machines?

When troubleshooting and repairing electric sealing machines, I follow a systematic approach:

- Identifying the problem through observation and diagnostics.

- Consulting technical manuals and diagrams to locate potential issues.

- Inspecting electrical components, sensors, and mechanical parts for defects or malfunctions.

- Replacing or repairing faulty components as necessary.

- Conducting thorough testing to ensure the machine is functioning correctly before returning it to operation.

4. What safety precautions do you observe while operating electric sealing machines?

To ensure a safe work environment, I adhere to the following safety precautions:

- Wearing appropriate personal protective equipment, such as gloves, safety glasses, and earplugs.

- Keeping work areas clean and clear of obstructions.

- Following lockout/tagout procedures when performing machine maintenance or repairs.

- Being aware of potential hazards, such as electrical shocks, moving parts, and hot surfaces.

- Reporting any unsafe conditions or equipment malfunctions immediately.

5. Describe your experience in maintaining and calibrating electric sealing machines.

Throughout my career, I have gained extensive experience in maintaining and calibrating electric sealing machines:

- Conducting regular inspections and cleaning to prevent malfunctions.

- Replacing worn or damaged parts, such as heating elements, pressure rollers, and sensors.

- Performing calibration procedures using specialized equipment to ensure accurate temperature and pressure settings.

- Documenting all maintenance and calibration activities for quality control purposes.

6. What types of sealing materials have you worked with, and what considerations do you make when choosing the appropriate material?

I have experience working with various sealing materials, including:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Laminated films

When choosing the appropriate sealing material, I consider factors such as:

- The type of product being packaged

- The required seal strength and integrity

- The compatibility of the material with the sealing machine

- The cost and availability of the material

7. How do you ensure that the sealed packages meet the required specifications and quality standards?

To ensure that sealed packages meet the required specifications and quality standards, I follow a comprehensive approach:

- Inspecting incoming materials to verify their compliance with specifications.

- Adhering to established sealing parameters and procedures.

- Conducting regular quality checks on sealed packages to assess seal strength, integrity, and appearance.

- Maintaining accurate records of quality control data.

- Implementing corrective actions when deviations from specifications are identified.

8. How do you prioritize your tasks and manage your time effectively in a fast-paced production environment?

In a fast-paced production environment, I prioritize my tasks and manage my time effectively through the following strategies:

- Creating a daily to-do list and prioritizing tasks based on urgency and importance.

- Breaking down large tasks into smaller, more manageable steps.

- Utilizing time management techniques, such as the Pomodoro Technique.

- Minimizing distractions and interruptions during work sessions.

- Delegating tasks to other team members when appropriate.

9. How do you stay up-to-date with advancements in electric sealing technology?

To stay up-to-date with advancements in electric sealing technology, I engage in the following activities:

- Attending industry conferences and workshops.

- Reading trade publications and online articles.

- Consulting with equipment manufacturers and suppliers.

- Participating in online forums and discussion groups.

- Seeking opportunities for professional development and training.

10. How would you handle a situation where you encounter a complex technical issue with an electric sealing machine that requires immediate attention?

When faced with a complex technical issue with an electric sealing machine that requires immediate attention, I follow a systematic troubleshooting process:

- Identifying the symptoms of the issue and gathering relevant information.

- Consulting technical manuals and diagrams to diagnose the potential cause.

- Inspecting electrical components, sensors, and mechanical parts for defects or malfunctions.

- Performing tests and measurements to isolate the root cause of the issue.

- Implementing appropriate corrective actions to resolve the issue promptly.

- Documenting the troubleshooting process and findings for future reference.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Sealing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Sealing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Sealing Machine Operators are responsible for operating and maintaining electric sealing machines used in various industries, such as packaging, manufacturing, and food processing. They ensure the proper sealing of products, ensuring the integrity and quality of the packaged items.

1. Machine Operation

Operate electric sealing machines to seal packages, containers, or products using heat, pressure, or a combination of both.

- Follow established procedures and protocols for machine operation.

- Adjust machine settings to achieve optimal sealing results based on product specifications and materials.

2. Quality Control

Inspect and verify the quality of sealed products to ensure they meet industry standards and customer requirements.

- Identify and resolve any sealing defects or issues promptly.

- Maintain records of inspections and quality control checks.

3. Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting tasks to ensure the smooth operation of sealing machines.

- Lubricate and clean machines regularly.

- Identify and resolve minor technical issues.

- Report major issues or breakdowns to supervisors promptly.

4. Safety and Compliance

Adhere to all safety protocols and regulations related to the operation of electric sealing machines.

- Wear appropriate personal protective equipment (PPE).

- Follow proper handling and storage procedures for hazardous materials.

- Maintain a clean and organized work area.

Interview Tips

Preparing thoroughly for an interview can significantly increase your chances of success. Here are some tips to help you ace your interview for an Electric Sealing Machine Operator position:

1. Research the Industry and Company

Familiarize yourself with the industry and the specific company you are applying to. Research their products, services, and market position. This will demonstrate your interest and enthusiasm for the role.

2. Highlight Relevant Experience

Emphasize any previous experience operating or working with sealing machines. Quantify your accomplishments and provide specific examples of how you contributed to the success of previous projects.

3. Demonstrate Quality Consciousness

Stress your commitment to quality control and attention to detail. Explain how you ensure the accuracy and consistency of your work and how you handle any quality issues that may arise.

4. Showcase Technical Skills

Highlight your technical skills related to machine operation, maintenance, and troubleshooting. Describe your proficiency in reading and interpreting technical documentation, as well as your ability to diagnose and resolve common issues.

5. Prepare for Common Interview Questions

Prepare answers to common interview questions, such as “Why are you interested in this role?” “What are your strengths and weaknesses?” and “How do you handle pressure?” Practice your responses to ensure they are clear, concise, and professional.

6. Dress Professionally and Be Punctual

Make a good first impression by dressing professionally and arriving on time for your interview. This shows respect for the interviewer and the company.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Sealing Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.