Are you gearing up for a career in Electric Solderer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Electric Solderer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

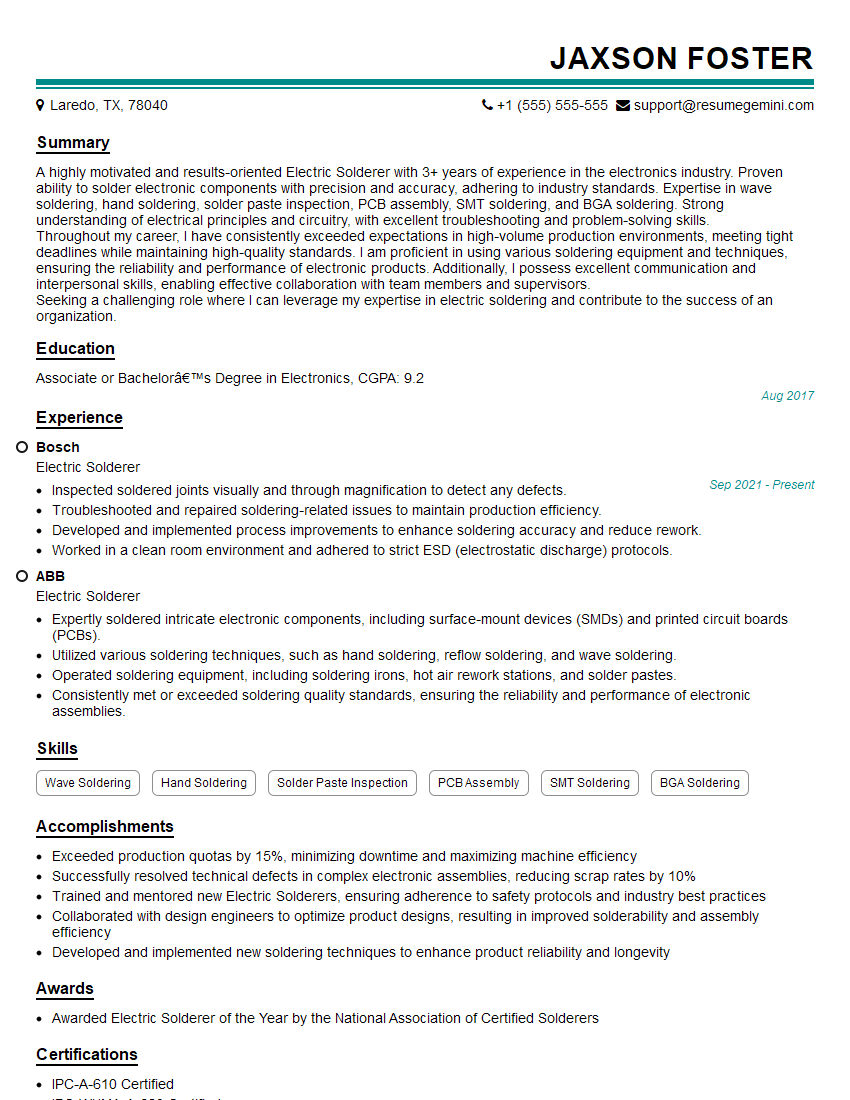

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electric Solderer

1. What are the different types of soldering irons?

There are three main types of soldering irons:

- Pencil soldering irons are the most common type. They are lightweight and easy to use, and they come in a variety of wattages.

- Soldering guns are more powerful than pencil soldering irons, and they are often used for soldering larger components.

- Soldering stations are the most advanced type of soldering iron. They offer precise temperature control and a variety of features, making them ideal for delicate soldering tasks.

2. What are the different types of solder?

There are two main types of solder:

- Lead-based solder is the most common type. It is inexpensive and easy to use, but it can be harmful to health.

- Lead-free solder is a safer alternative to lead-based solder. It is more expensive, but it is less harmful to health.

3. What are the different techniques for soldering?

There are two main techniques for soldering:

- Wave soldering is a mass soldering technique that is used to solder multiple components at once.

- Hand soldering is a manual soldering technique that is used to solder individual components.

4. What are the safety precautions that should be taken when soldering?

The following safety precautions should be taken when soldering:

- Wear eye protection to protect your eyes from flying solder.

- Wear gloves to protect your hands from heat and solder.

- Use a fume extractor to remove solder fumes from the air.

- Work in a well-ventilated area.

5. What are the common problems that can occur when soldering?

The following are some of the common problems that can occur when soldering:

- Cold solder joints occur when the solder does not fully melt and flow into the joint.

- Dry solder joints occur when there is not enough solder in the joint.

- Bridging occurs when solder flows between two closely spaced conductors.

- Solder balls occur when small droplets of solder form on the surface of the joint.

6. How do you troubleshoot soldering problems?

The following steps can be used to troubleshoot soldering problems:

- Inspect the joint for cold solder joints, dry solder joints, bridging, or solder balls.

- Check the soldering iron to make sure that it is at the correct temperature.

- Check the solder to make sure that it is the correct type and that it is clean.

- Clean the joint and the soldering iron tip.

- Re-solder the joint.

7. What are the different types of soldering fluxes?

The following are some of the different types of soldering fluxes:

- Rosin flux is the most common type of flux. It is made from pine sap and it is used to promote wetting and adhesion.

- Acid flux is more aggressive than rosin flux. It is used to clean metal surfaces before soldering.

- Water-soluble flux is a type of flux that can be removed with water. It is used for soldering electronic components.

8. What is the difference between solder paste and solder preforms?

Solder paste is a mixture of solder and flux that is applied to the solder joint before soldering. Solder preforms are pre-shaped pieces of solder that are placed on the solder joint before soldering.

9. What are the advantages of using a solder mask?

The following are some of the advantages of using a solder mask:

- Prevents solder from bridging between conductors.

- Protects the solder joint from environmental factors.

- Improves the appearance of the soldered joint.

10. What are the different types of soldering equipment?

The following are some of the different types of soldering equipment:

- Soldering irons

- Soldering guns

- Soldering stations

- Fume extractors

- Soldering masks

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electric Solderer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electric Solderer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electric Solderers play a vital role in manufacturing, assembling, and repairing electronic devices and components. Their primary responsibility is to join electrical components by melting solder onto their terminals and connecting them to circuit boards or other surfaces. The key job responsibilities of an Electric Solderer typically include:

1. Soldering Electrical Components

Electric Solderers are responsible for soldering electrical components, such as resistors, capacitors, and transistors, onto circuit boards. They use soldering irons or solder guns to melt solder and create electrical connections between the components and the board. Ensuring the accuracy and quality of these solder joints is crucial.

2. Assembling and Repairing Electronic Devices

Electric Solderers are involved in assembling and repairing electronic devices, such as computers, radios, and medical equipment. They may work on prototypes, production runs, or repair damaged devices. Their tasks include identifying and replacing faulty components, re-soldering connections, and ensuring the proper functioning of the devices.

3. Interpreting Technical Schematics and Drawings

Electric Solderers need to be able to read and interpret technical schematics and drawings to understand the design and layout of electronic circuits. These documents provide instructions on component placement, wiring, and soldering requirements. Accurate interpretation is essential for completing the soldering tasks correctly.

4. Maintaining a Clean and Organized Work Area

Maintaining a clean and organized work area is important for Electric Solderers. They need to keep their tools, materials, and equipment in good condition and ensure that the soldering area is free from clutter. This promotes safety, efficiency, and accuracy in their work.

Interview Tips

Preparing effectively for an Electric Solderer interview is crucial to make a positive impression and increase your chances of success. Here are some interview tips and hacks to help you ace the interview:

1. Research the Company and the Role

Before the interview, take the time to research the company you are applying to and the specific role you are interested in. Learn about their products, services, mission, and company culture. Understanding the company’s values and how they align with your own can demonstrate your genuine interest and enthusiasm for the position.

2. Practice Your Technical Skills

As an Electric Solderer, your technical skills will be a key focus of the interview. Consider practicing your soldering abilities before the interview. You can set up a practice board and work on making clean and precise solder joints. This will boost your confidence and help you showcase your skills during the interview.

3. Highlight Your Experience and Projects

During the interview, emphasize your relevant experience and projects. Quantify your accomplishments whenever possible to demonstrate the impact of your contributions. If you have worked on any notable projects related to soldering or electronics, be prepared to discuss them in detail.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the position and the company. Prepare a few questions related to the role, the company’s future plans, or any areas that you would like to know more about. This not only helps you gather more information but also demonstrates your enthusiasm and curiosity.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electric Solderer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!