Are you gearing up for a career in Electrical and Instrument Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Electrical and Instrument Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

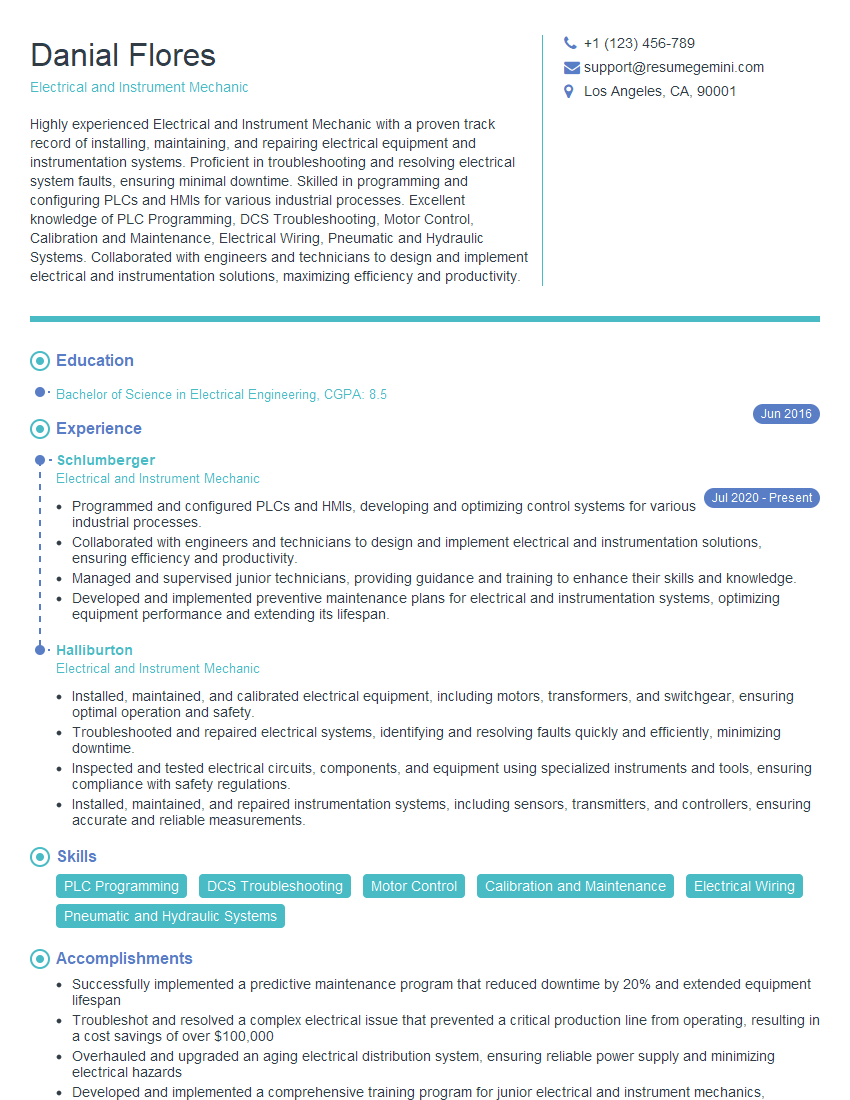

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical and Instrument Mechanic

1. How do you test an electrical motor for continuity?

To test an electrical motor for continuity, I follow these steps:

- Set the multimeter to the ohms setting.

- Touch one probe to one terminal of the motor and the other probe to the other terminal.

- If the multimeter reads zero ohms, the motor has continuity.

- If the multimeter reads infinite ohms, the motor does not have continuity.

2. Describe the purpose of each component in a three-phase electrical motor.

Stator

- Converts electrical energy into magnetic energy.

- Consists of a set of coils wound around a laminated iron core.

Rotor

- Converts magnetic energy into mechanical energy.

- Consists of a set of conductors mounted on a laminated iron core.

Terminal Box

- Provides a means of connecting the motor to the power supply.

- Contains terminals for each phase of the motor.

3. What are the common causes of electrical motor failure?

Common causes of electrical motor failure include:

- Overheating

- Overloading

- Bearing failure

- Electrical insulation failure

- Environmental factors (e.g., moisture, dust)

4. How do you troubleshoot an electrical control circuit?

To troubleshoot an electrical control circuit, I follow these steps:

- Verify that the power supply is on.

- Check for loose connections.

- Test the continuity of the circuit.

- Identify the faulty component.

- Replace the faulty component.

5. What are the different types of electrical sensors?

There are many different types of electrical sensors, including:

- Temperature sensors

- Pressure sensors

- Flow sensors

- Level sensors

- Proximity sensors

6. How do you calibrate an electrical instrument?

To calibrate an electrical instrument, I follow these steps:

- Compare the instrument’s reading to a known standard.

- Adjust the instrument’s reading to match the standard.

- Repeat this process for several different values.

7. What are the safety precautions that should be taken when working on electrical equipment?

When working on electrical equipment, it is important to take the following safety precautions:

- Lock out/tag out the equipment.

- Wear appropriate personal protective equipment (PPE).

- Use proper tools and equipment.

- Follow all safety procedures.

8. How do you maintain electrical equipment?

To maintain electrical equipment, I follow these steps:

- Inspect the equipment regularly.

- Clean the equipment regularly.

- Lubricate the equipment regularly.

- Test the equipment regularly.

- Keep records of all maintenance activities.

9. What are the troubleshooting techniques for electrical equipment?

Common troubleshooting techniques for electrical equipment include:

- Visual inspection

- Electrical testing

- Mechanical testing

- Software testing

10. What are the different types of electrical equipment used in industrial settings?

Common types of electrical equipment used in industrial settings include:

- Motors

- Generators

- Transformers

- Control panels

- Sensors

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical and Instrument Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical and Instrument Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrical and Instrument Mechanics install, maintain, and repair electrical and instrumentation systems and equipment in industrial and commercial settings. Their primary responsibilities include:

1. Installation and Maintenance

Installing, testing, and commissioning electrical and instrumentation systems, including wiring, panels, motors, and sensors; Performing preventive maintenance on electrical and instrumentation systems, including inspections, cleaning, and lubrication

2. Troubleshooting and Repair

Troubleshooting electrical and instrumentation faults and malfunctions; Repairing and replacing faulty components, such as wires, cables, connectors, and sensors;

3. Calibration and Adjustment

Calibrating and adjusting electrical and instrumentation systems to ensure accuracy and reliability; Using specialized tools and equipment to test and verify the performance of systems;

4. Documentation and Reporting

Maintaining accurate records of work performed, including electrical diagrams, schematics, and maintenance reports; Communicating with supervisors, engineers, and other personnel to provide updates on system status and maintenance requirements.

Interview Tips and Preparation

To prepare effectively for an Electrical and Instrument Mechanic interview, consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products or services, and culture; Review the job description thoroughly and identify the key responsibilities and qualifications.

2. Practice Answering Common Interview Questions

Prepare for questions about your experience in electrical and instrumentation maintenance; – Example Outline: “Describe a complex electrical or instrumentation system you have worked on, and explain the steps you took to troubleshoot and repair it.” Prepare for questions about your technical skills and knowledge; – Example Outline: “Explain the principles of electrical circuits, including Ohm’s Law and Kirchhoff’s Laws.” Expect questions about your safety practices and understanding of industry standards and regulations; – Example Outline: “Describe the safety precautions you follow when working with electrical equipment, and explain the importance of adhering to industry standards.”

3. Highlight Relevant Experience and Skills

Quantify your accomplishments and provide specific examples of your work; – Example Outline: “In my previous role, I reduced electrical system downtime by 25% through proactive maintenance and troubleshooting.” Emphasize your proficiency in electrical and instrumentation maintenance techniques and technologies; – Example Outline: “I am highly skilled in electrical wiring, circuit analysis, and the use of diagnostic equipment.” Showcase your problem-solving abilities and attention to detail.

4. Prepare Questions for the Interviewer

Asking thoughtful questions demonstrates your interest in the position and the company; Questions could be about the company’s growth plans, the challenges and opportunities within the role, or the company’s commitment to safety and professional development.

5. Dress Professionally and Arrive on Time

First impressions matter, dress appropriately for the industry and company culture. Punctuality shows respect for the interviewer’s time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electrical and Instrument Mechanic interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!