Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Electrical and Instrumentation Mechanic interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Electrical and Instrumentation Mechanic so you can tailor your answers to impress potential employers.

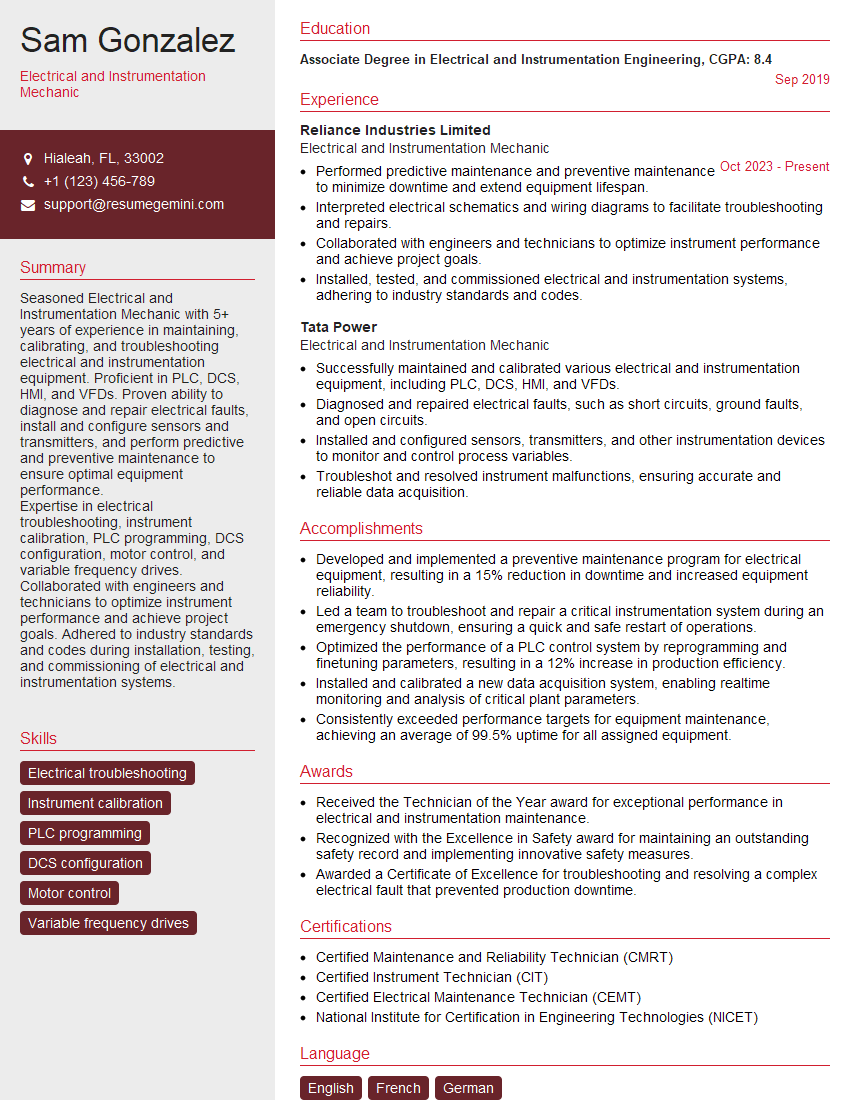

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical and Instrumentation Mechanic

1. Explain the purpose and working principle of a Programmable Logic Controller (PLC)?

A Programmable Logic Controller (PLC) is an industrial computer used to automate processes in manufacturing and other industries. It is a ruggedized computer system that can withstand the harsh conditions of a factory floor. PLCs are programmed using ladder logic, a graphical programming language that is easy to learn and use.

- When a PLC is programmed, it reads the program and creates a set of instructions that it follows to control the process.

- The PLC then scans the input devices (such as sensors and switches) and updates the output devices (such as actuators and motors) accordingly.

2. Describe the different types of sensors used in industrial settings and their applications?

Temperature sensors

- Thermocouples

- Resistance Temperature Detectors (RTDs)

- Thermistors

Pressure sensors

- Strain gauges

- Diaphragm pressure sensors

- Piezoresistive pressure sensors

Flow sensors

- Turbine flow meters

- Vortex shedding flow meters

- Magnetic flow meters

3. Explain the operation of a DC motor and how it differs from an AC motor?

A DC motor is an electric motor that uses direct current (DC) to create a magnetic field. The magnetic field interacts with the windings on the motor’s rotor, causing it to rotate. DC motors are typically used in low-power applications, such as small appliances and electric vehicles.

AC motors, on the other hand, use alternating current (AC) to create a magnetic field. The magnetic field reverses direction at a regular interval, causing the rotor to rotate. AC motors are typically used in high-power applications, such as industrial machinery and power tools.

Key differences between DC motors and AC motors

- DC motors use direct current, while AC motors use alternating current.

- DC motors have a commutator, while AC motors do not.

- DC motors have a higher starting torque than AC motors.

- AC motors are more efficient than DC motors.

4. How would you troubleshoot a faulty electrical system?

To troubleshoot a faulty electrical system, I would first check the power supply to ensure that it is functioning properly. I would then use a multimeter to test the voltage and continuity of the wires and components in the system. If I find any faults, I would repair or replace the faulty components.

- If the system is still not working properly, I would check the software and firmware to ensure that they are up to date and functioning properly.

- I would also check the system’s logs and error messages to see if there are any clues to the problem.

5. What are some of the safety precautions you take when working with electrical equipment?

- I always wear appropriate safety gear, including safety glasses, gloves, and a hard hat.

- I always check the equipment before using it to ensure that it is in good condition and that all of the safety features are functioning properly.

- I never work on live electrical equipment.

- I always follow the manufacturer’s instructions for the equipment that I am using.

- I am aware of the hazards of working with electricity and I take all necessary precautions to avoid accidents.

6. What is your experience with industrial automation?

I have experience with a variety of industrial automation systems, including PLCs, SCADA systems, and distributed control systems (DCSs). I have used these systems to automate a variety of processes, including manufacturing, packaging, and material handling.

- I am familiar with the programming languages used in industrial automation, such as ladder logic and structured text.

- I have also worked with a variety of industrial automation protocols, such as Modbus and Profibus.

7. What is your experience with electrical maintenance?

I have experience with a variety of electrical maintenance tasks, including troubleshooting, repair, and replacement of electrical components. I have also worked on a variety of electrical systems, including power distribution systems, lighting systems, and control systems.

- I am familiar with the National Electrical Code (NEC) and other electrical safety codes.

- I am also experienced in the use of electrical test equipment, such as multimeters, oscilloscopes, and power analyzers.

8. What is your experience with instrumentation?

I have experience with a variety of instrumentation devices, including sensors, transmitters, and controllers. I have used these devices to measure and control a variety of process variables, such as temperature, pressure, and flow.

- I am familiar with the principles of operation of a variety of instrumentation devices.

- I have also worked with a variety of instrumentation protocols, such as HART and Foundation Fieldbus.

9. What are your strengths and weaknesses as an Electrical and Instrumentation Mechanic?

Strengths

- I have a strong understanding of electrical and instrumentation principles.

- I have experience with a variety of electrical and instrumentation systems.

- I am a quick learner and I am always willing to take on new challenges.

Weaknesses

- I am not as experienced as some other candidates with industrial automation.

- I am not as familiar with some of the latest instrumentation technologies.

10. Why are you interested in this position?

I am interested in this position because it is a great opportunity to use my skills and experience to contribute to the success of your company. I am also excited about the chance to work with a team of experienced professionals and to learn from them.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical and Instrumentation Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical and Instrumentation Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrical and Instrumentation Mechanics play a crucial role in ensuring the smooth operation of electrical and instrumentation systems in various industries. Their key responsibilities include:

1. Installation and Maintenance

Installing, maintaining, and repairing electrical and instrumentation systems, including wiring, lighting, control panels, and sensors.

- Diagnose and troubleshoot electrical and instrumentation system malfunctions.

- Perform regular inspections and preventive maintenance to ensure optimal performance and safety.

2. Calibration and Testing

Calibrating and testing electrical and instrumentation equipment to ensure accuracy and reliability.

- Use specialized tools and equipment for calibration and testing.

- Prepare and maintain calibration records.

3. Troubleshooting and Repair

Responding to emergencies, diagnosing problems, and repairing electrical and instrumentation systems.

- Identify and isolate faults in electrical systems using multimeters, oscilloscopes, and other diagnostic tools.

- Repair or replace faulty components, such as switches, fuses, and relays.

4. Documentation and Compliance

Maintaining detailed records of installation, maintenance, and repair work.

- Prepare and submit technical reports, maintenance logs, and work orders.

- Ensure compliance with electrical codes, safety regulations, and industry standards.

Interview Tips

Preparing for an interview for an Electrical and Instrumentation Mechanic position requires thorough preparation and knowledge of the industry. Here are some tips to help you ace the interview:

1. Research the Company and Position

Gather information about the company’s industry, size, products or services, and the specific requirements of the Electrical and Instrumentation Mechanic position.

- Visit the company website, read industry news, and connect with current or former employees on LinkedIn.

- Thoroughly review the job description and highlight your skills and experience that align with the requirements.

2. Highlight Your Technical Skills

Emphasize your technical skills in electrical and instrumentation systems, including wiring, troubleshooting, and repair.

- Provide specific examples of projects where you successfully installed, maintained, or repaired electrical and instrumentation systems.

- Quantify your accomplishments whenever possible, using metrics such as time saved, cost reductions, or improved efficiency.

3. Showcase Your Problem-Solving Abilities

Interviewers want to know how you approach and solve problems. Share examples of how you identified, diagnosed, and resolved electrical or instrumentation issues.

- Use the STAR method (Situation, Task, Action, Result) to describe your problem-solving experiences.

- Emphasize your ability to think critically, collaborate with others, and find creative solutions.

4. Prepare for Common Interview Questions

Practice answering common interview questions, such as:

- Tell me about your experience in electrical and instrumentation.

- Describe a time when you faced a challenging electrical issue and how you resolved it.

- Why are you interested in this position and our company?

- What are your strengths and weaknesses as an Electrical and Instrumentation Mechanic?

- Do you have any questions for us?

Next Step:

Now that you’re armed with the knowledge of Electrical and Instrumentation Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Electrical and Instrumentation Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini