Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electrical Calibrator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

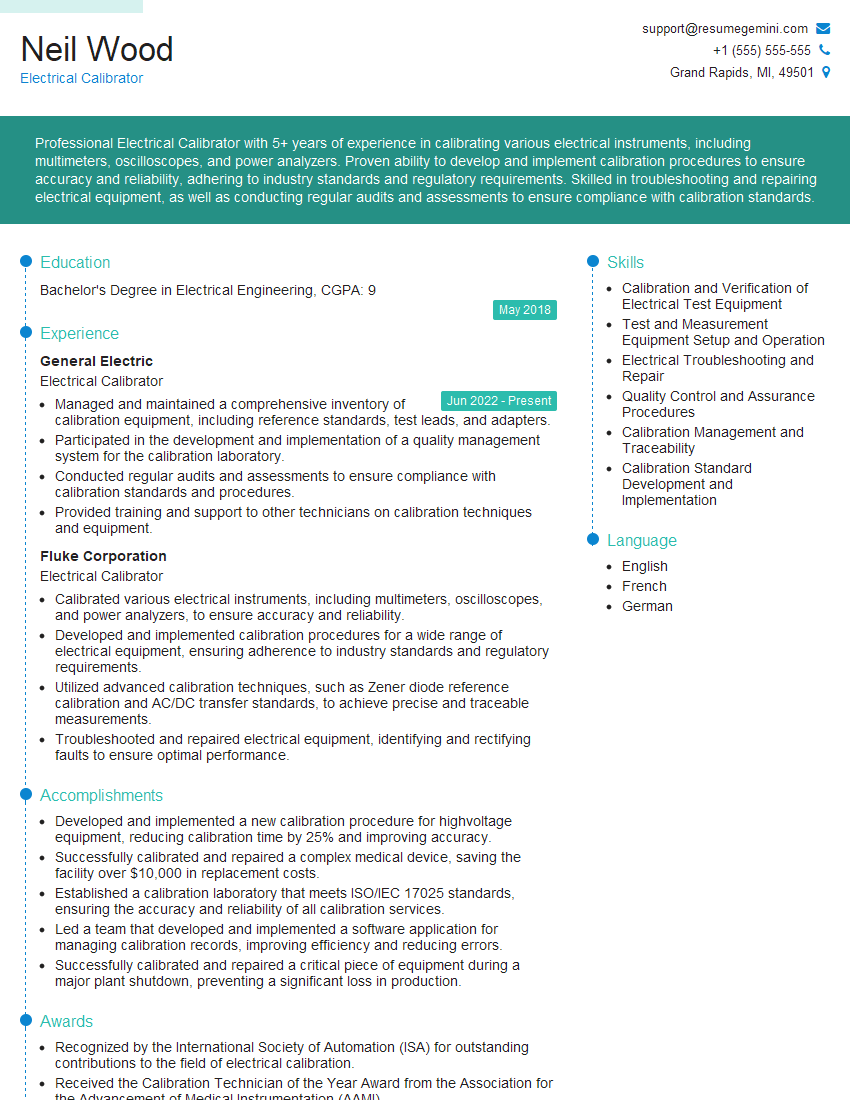

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical Calibrator

1. Explain the primary responsibilities of an Electrical Calibrator?

As an Electrical Calibrator, my key responsibilities would include:

- Precisely calibrating and adjusting electrical instruments and devices, ensuring they meet specified accuracy standards.

- Thoroughly documenting calibration procedures, findings, and any necessary adjustments for each piece of equipment.

- Diagnosing electrical faults and recommending corrective actions to maintain optimal equipment performance.

- Providing ongoing technical support to ensure calibrated instruments continue to function accurately.

- Maintaining a thorough understanding of calibration standards and best practices to ensure adherence.

2. What are the essential tools and equipment used in electrical calibration?

Benchtop Tools:

- Multimeters (digital and analog)

- Variable power supplies

- Signal generators

- Oscilloscopes

Handheld Tools:

- Clamp meters

- Calibrator testers

- Insulation testers

Software and Standards:

- Calibration management software

- ISO 17025:2017

- IEC 61280-4-1

3. Describe the process of calibrating a multimeter using a reference voltage source?

Calibrating a multimeter using a reference voltage source involves the following steps:

- Connect the reference voltage source to the multimeter’s input terminals.

- Set the multimeter to the appropriate voltage range.

- Adjust the reference voltage source to the desired output voltage.

- Compare the multimeter’s reading to the reference voltage.

- Make any necessary adjustments to the multimeter’s calibration settings to ensure its reading matches the reference voltage.

- Document the calibration procedure and results.

4. What are the different types of calibration methods used for electrical instruments?

The primary calibration methods used for electrical instruments include:

- Direct calibration: Comparing the instrument’s reading to a known reference standard.

- Indirect calibration: Using a calibrated device to calibrate another device.

- Autocalibration: Using an instrument’s built-in calibration features to adjust its own settings.

- Closed-loop calibration: Using feedback from the instrument being calibrated to adjust the reference standard.

5. How do you ensure the accuracy and traceability of your calibration results?

To ensure the accuracy and traceability of my calibration results, I follow these practices:

- Using calibrated and traceable reference standards that are regularly checked and verified.

- Following documented calibration procedures that are in accordance with industry standards.

- Maintaining calibration records that include all relevant data, including instrument readings, reference values, and any adjustments made.

- Participating in ongoing training and professional development to stay up-to-date on calibration techniques and standards.

6. Describe your experience with calibrating electrical sensors, such as pressure transducers and temperature probes?

In my previous role, I was responsible for calibrating a wide range of electrical sensors, including pressure transducers and temperature probes.

- For pressure transducers, I used a pressure calibrator to apply a known pressure to the transducer and measured the output signal.

- For temperature probes, I used a temperature bath to create a known temperature environment and measured the probe’s output signal.

- I compared the measured output signals to the manufacturer’s specifications and made any necessary adjustments to ensure accuracy.

7. How do you handle situations where the instrument being calibrated fails to meet the specified accuracy requirements?

In cases where an instrument fails to meet the specified accuracy requirements, I take the following steps:

- I repeat the calibration process to confirm the initial results.

- I examine the instrument for any obvious defects or damage.

- I consult with the manufacturer or other experts to gather insights on potential causes.

- I recommend repairs or adjustments as necessary.

- I document the issue and any corrective actions taken.

8. What are the common sources of errors in electrical calibration and how do you minimize them?

Common sources of errors in electrical calibration include:

- Environmental factors (temperature, humidity, vibration)

- Instrument drift

- Reference standard errors

- Human error

To minimize errors, I take the following precautions:

- Controlling the calibration environment to minimize external influences.

- Using high-quality reference standards and regularly verifying their accuracy.

- Following documented procedures and minimizing manual adjustments.

- Thoroughly documenting the calibration process and results.

9. How do you stay up-to-date on the latest calibration techniques and industry standards?

To stay current with the latest calibration techniques and industry standards, I engage in the following activities:

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in professional organizations (e.g., IEEE).

- Seeking certifications and training opportunities.

10. How do you ensure the confidentiality of sensitive calibration data and information?

To ensure the confidentiality of sensitive calibration data and information, I adhere to the following principles:

- Restricting access to calibration data and records to authorized personnel only.

- Using secure storage methods for both physical and digital records.

- Complying with all applicable data protection regulations and standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical Calibrator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical Calibrator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrical Calibrators are responsible for the maintenance and calibration of electrical equipment, ensuring its accuracy and reliability. Their key job responsibilities include:

1. Electrical Equipment Calibration

Using specialized tools and techniques, they calibrate a wide range of electrical equipment, including meters, gauges, transducers, and power analyzers.

- Traceability to national and international standards

- Documentation and record-keeping for calibration activities

2. Equipment Inspection and Troubleshooting

Regularly inspect electrical equipment to identify potential issues and perform troubleshooting to resolve any problems.

- Identify and resolve electrical faults and malfunctions

- Recommend and implement corrective actions

3. Calibration Procedure Development and Improvement

Develop and improve calibration procedures to ensure accuracy and efficiency.

- Review and update existing calibration procedures

- Implement new technologies and techniques

4. Collaboration and Training

Collaborate with other departments and provide training to ensure proper use and maintenance of calibrated equipment.

- Provide technical guidance to users and staff

- Participate in quality improvement initiatives

Interview Tips

To ace an interview for an Electrical Calibrator position, it’s crucial to demonstrate your technical expertise, attention to detail, and problem-solving abilities. Here are some tips:

1. Research the Company and Role

Thoroughly research the company and the specific role to understand their business, industry, and the required skills and responsibilities.

- Visit the company website

- Read industry publications and news

2. Highlight Your Technical Skills

Emphasize your proficiency in calibration techniques, equipment, and industry standards. Provide specific examples of your work and how you ensured accuracy and reliability.

- Discuss your experience with different electrical instruments

- Explain your understanding of calibration principles and methodologies

3. Demonstrate Problem-Solving Abilities

Highlight your ability to troubleshoot and resolve electrical issues. Share examples of how you identified and fixed problems, ensuring equipment functionality.

- Describe a situation where you diagnosed a complex electrical fault

- Explain your approach to problem-solving and decision-making

4. Showcase Attention to Detail

Emphasize your meticulousness and attention to detail in calibration procedures. Explain how you ensure accuracy and maintain records to meet regulatory requirements.

- Highlight your experience in documentation and record-keeping

- Describe how you maintain traceability and compliance with standards

5. Prepare for Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers. Research industry trends and be ready to discuss your knowledge and insights.

- Explain the importance of calibration in electrical systems

- Discuss emerging trends in calibration technologies

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Electrical Calibrator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Electrical Calibrator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.