Are you gearing up for an interview for a Electrical Discharge Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Electrical Discharge Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

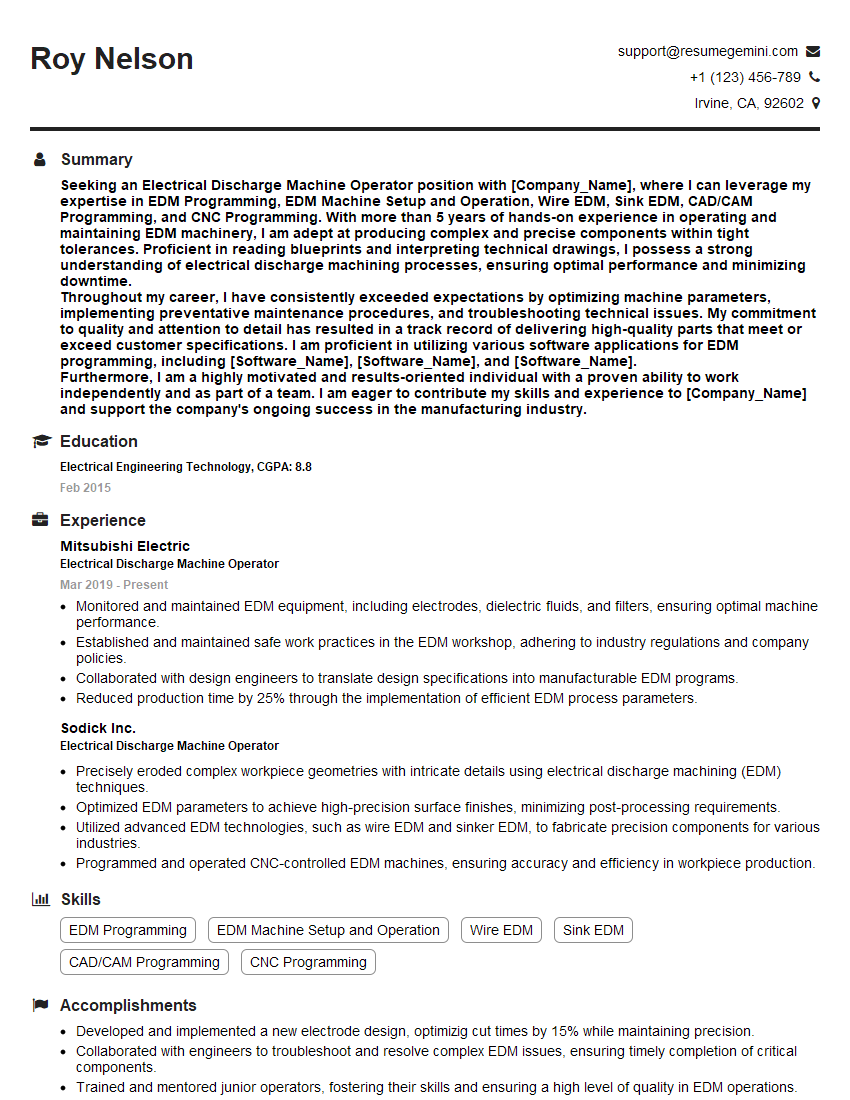

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical Discharge Machine Operator

1. Explain the working principle of an Electrical Discharge Machine (EDM)?

An EDM (Electrical Discharge Machine) works on the principle of spark erosion, removing material from a workpiece by a series of electrical discharges between two electrodes.

- Controlled Sparks: The EDM machine creates controlled electrical sparks through a dielectric fluid.

- Erosion Process: The electrical sparks generate intense heat, melting and eroding the workpiece material.

- Dielectric Fluid: The dielectric fluid, such as deionized water or oil, acts as a non-conductive medium, allowing for spark formation and cooling.

- Electrode Wear: As the spark erodes the workpiece, the electrode also experiences wear, resulting in the need for electrode dressing.

2. What are the different types of EDM processes and their applications?

Wire EDM

- Uses a thin wire as the electrode to create precise and complex shapes.

- Ideal for cutting intricate contours, small holes, and delicate parts.

Sinker EDM

- Uses a shaped electrode to plunge into the workpiece, creating cavities and complex forms.

- Suitable for mold making, stamping, and hard-to-machine materials.

Ram EDM

- Similar to sinker EDM, but the electrode is fixed and the workpiece moves along three axes.

- Provides greater flexibility and accessibility for machining deep or complex cavities.

3. Describe the steps involved in programming an EDM machine?

- Design and CAD: Create a 2D or 3D model of the desired part.

- CAM Software: Convert the design into a machine-readable code using CAM software.

- Toolpath Generation: Define the path of the electrode through the workpiece, optimizing speed, feed, and spark parameters.

- Machine Setup: Install the workpiece, electrode, and dielectric fluid in the machine.

- Calibration: Verify the setup and calibrate the machine to ensure accurate machining.

4. How do you maintain the quality and accuracy of EDM operations?

- Electrode Selection and Dressing: Use appropriate electrode materials and ensure proper dressing to minimize wear and maintain shape.

- Dielectric Fluid Maintenance: Regularly filter and replenish the dielectric fluid to maintain its dielectric properties and cooling ability.

- Machine Calibration and Maintenance: Perform regular calibration and maintenance of the machine, including alignment checks and axis adjustments.

- Surface Preparation: Clean and prepare the workpiece surface to promote proper bonding with the dielectric fluid.

- Process Monitoring: Observe the machining process and adjust parameters as needed to ensure optimal performance and quality.

5. What are the safety precautions to be observed while operating an EDM machine?

- Electrical Hazards: Wear protective clothing, gloves, and eye protection to prevent electrical shocks.

- Sparks and Debris: Use enclosures and shields to protect against sparks and ejected debris.

- Chemical Safety: Handle dielectric fluids properly and dispose of them according to regulations.

- Eye Protection: Wear appropriate eye protection to prevent eye damage from sparks and UV radiation.

- Noise Protection: Use earplugs or noise-canceling headphones to reduce exposure to noise.

6. Explain the role of dielectric fluid in an EDM process?

Dielectric fluid in EDM plays multifaceted roles:

- Non-Conductive Medium: It acts as an insulating medium between the workpiece and the electrode, preventing short circuits.

- Cooling Agent: It absorbs and dissipates heat generated during the spark discharge, preventing thermal damage to the workpiece and electrode.

- Debris Removal: The dielectric fluid helps flush away debris and molten material from the machining zone, ensuring a clean cutting process.

- Dielectric Strength: It provides sufficient dielectric strength to sustain the electrical discharge without breaking down.

7. How do you select the appropriate electrode material and shape for an EDM operation?

- Material Properties: Consider the material properties of the workpiece, such as hardness, conductivity, and melting point.

- Electrode Wear: Choose materials with low electrode wear to minimize electrode consumption and maintain accuracy.

- Thermal Conductivity: Select materials with high thermal conductivity to effectively dissipate heat and prevent electrode damage.

- Shape: Determine the electrode shape based on the geometry of the desired cavity or cut.

8. Describe the process of wire threading and tensioning in wire EDM?

- Wire Preparation: Cut and prepare the wire to the appropriate length and diameter.

- Wire Threading: Guide the wire through the wire guides and rollers of the machine.

- Tensioning: Apply the appropriate tension to the wire to ensure stability and prevent breakage during machining.

- Wire Breakage Monitoring: Use sensors to monitor the wire for breakage and automatically stop the machine if necessary.

9. How do you troubleshoot and resolve common EDM problems, such as poor surface finish or excessive electrode wear?

- Poor Surface Finish: Adjust spark parameters (pulse duration, peak current), check dielectric fluid cleanliness, and optimize electrode geometry.

- Excessive Electrode Wear: Select a more wear-resistant electrode material, reduce spark intensity, or modify the machining strategy.

- Electrical Arcing: Ensure proper workpiece grounding, check dielectric fluid dielectric strength, and inspect for electrode contamination.

- Wire Breakage: Verify wire tension, adjust wire guides, and check for any obstructions in the wire path.

10. What are the recent advancements in EDM technology, such as micro-EDM or dry EDM?

- Micro-EDM: Used for ultra-precise machining of micro-sized features and complex geometries.

- Dry EDM: Eliminates the need for dielectric fluid, providing advantages in environmental friendliness and reduced machining time.

- Hybrid EDM: Combines EDM with other machining processes, such as milling or laser cutting, for improved efficiency and versatility.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical Discharge Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical Discharge Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrical Discharge Machine Operators are responsible for operating and maintaining electrical discharge machines (EDMs) to create precision parts for industries like aerospace, automotive, and medical device manufacturing.

1. Machine Operation

Operate EDMs to create complex shapes and contours in metal workpieces.

- Set up and adjust EDM machines according to blueprints and specifications.

- Program and control machines to execute cutting operations.

- Monitor machine performance and make adjustments as needed.

2. Material Handling

Handle and secure workpieces in the EDM machine.

- Inspect workpieces to ensure they meet specifications.

- Remove finished parts from the machine and clean them.

3. Maintenance and Troubleshooting

Perform routine maintenance on EDMs to ensure optimal performance.

- Clean and lubricate machines.

- Inspect and replace worn or damaged parts.

- Troubleshoot and resolve machine malfunctions.

4. Quality Control

Ensure the quality of parts produced by EDMs.

- Use measuring tools and gauges to inspect parts for accuracy and precision.

- identify and correct any defects in the parts.

- Maintain records of inspection results.

Interview Tips

Preparing thoroughly for an Electrical Discharge Machine Operator interview can significantly increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Research the company you’re applying to, including their industry, products, and culture. This will help you understand the company’s needs and how you can contribute.

- Visit the company’s website and social media pages.

- Read news articles and industry blogs about the company.

- Check out the company’s LinkedIn profile.

2. Practice Your Answers

Anticipate common interview questions and prepare your answers in advance. This will help you speak confidently and clearly during the interview.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on highlighting your skills and experience that are relevant to the job.

- Practice your answers with a friend or family member.

3. Dress Professionally

First impressions matter, so dress professionally for your interview. This shows the interviewer that you respect the opportunity and are serious about the job.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Avoid wearing strong perfumes or colognes.

4. Be Enthusiastic and Positive

Interviewers are looking for candidates who are enthusiastic and passionate about the job. Show the interviewer that you’re excited about the opportunity and that you’re confident in your abilities.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Be positive and upbeat throughout the interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electrical Discharge Machine Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.