Are you gearing up for a career in Electrical Instrument Maker? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Electrical Instrument Maker and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

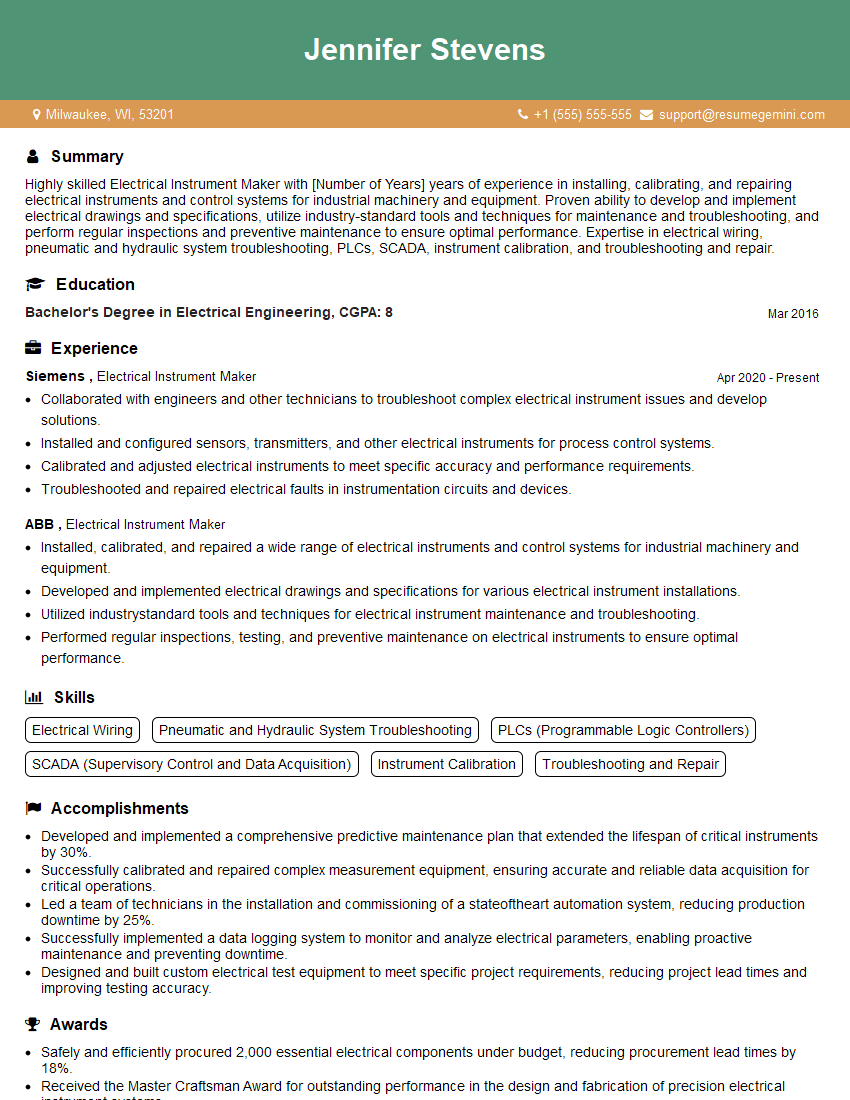

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical Instrument Maker

1. Explain the process of calibrating and troubleshooting pressure sensors?

- Determining the required accuracy and range of the sensor

- Connecting the sensor to a pressure source and a calibration device

- Applying a range of pressures to the sensor and recording the output

- Comparing the output to the expected values and making adjustments as necessary

- Troubleshooting common problems such as sensor drift, noise, and linearity issues

2. How do you ensure the accuracy and reliability of electrical instruments?

Calibration and Maintenance

- Regularly calibrate instruments using certified standards

- Follow recommended maintenance schedules to prevent drift and ensure optimal performance

Proper Usage and Handling

- Use instruments within their specified operating ranges

- Handle instruments carefully to avoid damage and maintain accuracy

Environmental Considerations

- Consider temperature, humidity, and other environmental factors that may affect instrument performance

- Use instruments in environments that meet the specified operating conditions

3. Describe the different types of electrical instruments used in industrial settings and their applications?

- Voltmeters: Measure voltage (AC/DC)

- Ammeters: Measure current (AC/DC)

- Ohmmeters: Measure resistance

- Power meters: Measure power consumption

- Insulation testers: Test the insulation resistance of electrical systems

- Clamp meters: Measure current without breaking the circuit

- Frequency counters: Measure the frequency of electrical signals

- Oscilloscopes: Visualize electrical waveforms

4. Explain the safety precautions you take when working with electrical instruments?

- Wear appropriate personal protective equipment (PPE)

- Ensure proper grounding and insulation

- Verify circuit de-energization before working

- Use insulated tools and equipment

- Follow established safety protocols and procedures

- Remain aware of potential hazards and maintain a safe working environment

5. How do you interpret electrical schematics and wiring diagrams?

- Identify symbols and components used in the schematic

- Trace signal paths and connections between components

- Understand the function and purpose of each component and circuit

- Recognize and interpret different types of diagrams, such as single-line diagrams and block diagrams

- Analyze the schematics to identify potential issues and develop troubleshooting strategies

6. Explain the principles of electrical grounding and its importance in electrical systems?

- Grounding provides a low-resistance path to the earth for electrical currents

- It protects equipment and personnel from electrical shocks and damage

- Grounding helps stabilize voltage levels and prevents electrical noise

- Proper grounding ensures the safe and reliable operation of electrical systems

7. Describe the process of troubleshooting electrical circuits and identifying common faults?

- Gather information about the system and symptoms

- Visually inspect components and connections

- Use electrical instruments to measure voltage, current, and resistance

- Analyze the measurements to identify potential faults

- Replace or repair faulty components and connections

- Verify the system’s functionality and safety after troubleshooting

8. Explain the different types of electrical enclosures used in industrial settings and their applications?

- NEMA 1: General-purpose enclosures, protect against dust and light moisture

- NEMA 3: Weather-proof enclosures, protect against rain, sleet, snow, and dust

- NEMA 4: Water-tight enclosures, protect against water spray and splashing

- NEMA 7: Hazardous location enclosures, protect against explosive atmospheres

- NEMA 9: Corrosive-resistant enclosures, protect against acids, bases, and other corrosive materials

9. Describe your experience with electrical safety standards and regulations?

- Familiar with industry standards such as NEC and IEC

- Understand the importance of adhering to safety codes and regulations

- Experienced in implementing safety measures and procedures

10. Explain how you stay up-to-date with advancements in electrical instrument technology?

- Attend industry conferences and training programs

- Read technical journals and articles

- Network with other professionals in the field

- Explore online resources and manufacturer websites

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical Instrument Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical Instrument Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrical Instrument Makers are responsible for the installation, maintenance, and repair of electrical instruments used in industrial settings. These instruments include sensors, transmitters, controllers, and recorders. They work with blueprints and schematics to ensure that instruments are installed and maintained according to specifications.

1. Installation of Electrical Instruments

Electrical Instrument Makers install electrical instruments in accordance with blueprints and schematics. They use a variety of tools and equipment to connect instruments to wiring and other components.

- Follow blueprints and schematics to determine the location and orientation of instruments

- Connect instruments to wiring and other components using a variety of tools and equipment

- Test instruments to ensure that they are functioning properly

2. Maintenance of Electrical Instruments

Electrical Instrument Makers perform regular maintenance on electrical instruments to ensure that they are operating properly. They inspect instruments for wear and tear, clean and lubricate moving parts, and calibrate instruments to ensure accuracy.

- Inspect instruments for wear and tear

- Clean and lubricate moving parts

- Calibrate instruments to ensure accuracy

- Repair or replace damaged instruments

3. Troubleshooting Electrical Instruments

Electrical Instrument Makers troubleshoot electrical instruments to identify and correct problems. They use a variety of diagnostic tools and techniques to identify the source of problems and develop solutions.

- Use diagnostic tools and techniques to identify the source of problems

- Develop and implement solutions to correct problems

- Document troubleshooting and repair procedures

4. Safety

Electrical Instrument Makers must follow all safety regulations when working with electrical equipment. They must be aware of the hazards of working with electricity and take precautions to avoid accidents.

- Follow all safety regulations when working with electrical equipment

- Be aware of the hazards of working with electricity

- Take precautions to avoid accidents

Interview Tips

Preparing for an interview for an Electrical Instrument Maker position can be daunting, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and in news articles.

- Visit the company’s website to learn about their history, mission, and values.

- Read news articles and social media posts about the company to get an idea of their recent activities and accomplishments.

- Review the job description carefully to identify the key requirements of the position.

2. Practice Answering Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

- Prepare an elevator pitch that summarizes your skills and experience.

- Practice answering common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Be prepared to discuss your experience with electrical instruments and your troubleshooting skills.

3. Prepare Questions to Ask the Interviewer

Asking questions at the end of an interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position. Prepare a few questions in advance so that you can ask them if you have the opportunity.

- Ask about the company’s culture and values.

- Ask about the specific responsibilities of the position.

- Ask about the company’s plans for the future.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time for your interview. This shows that you are respectful of the interviewer’s time and that you are serious about the position.

- Wear a suit or business casual attire.

- Arrive on time for your interview.

- Be polite and respectful to the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electrical Instrument Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!