Are you gearing up for a career in Electrical Line Splicer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Electrical Line Splicer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

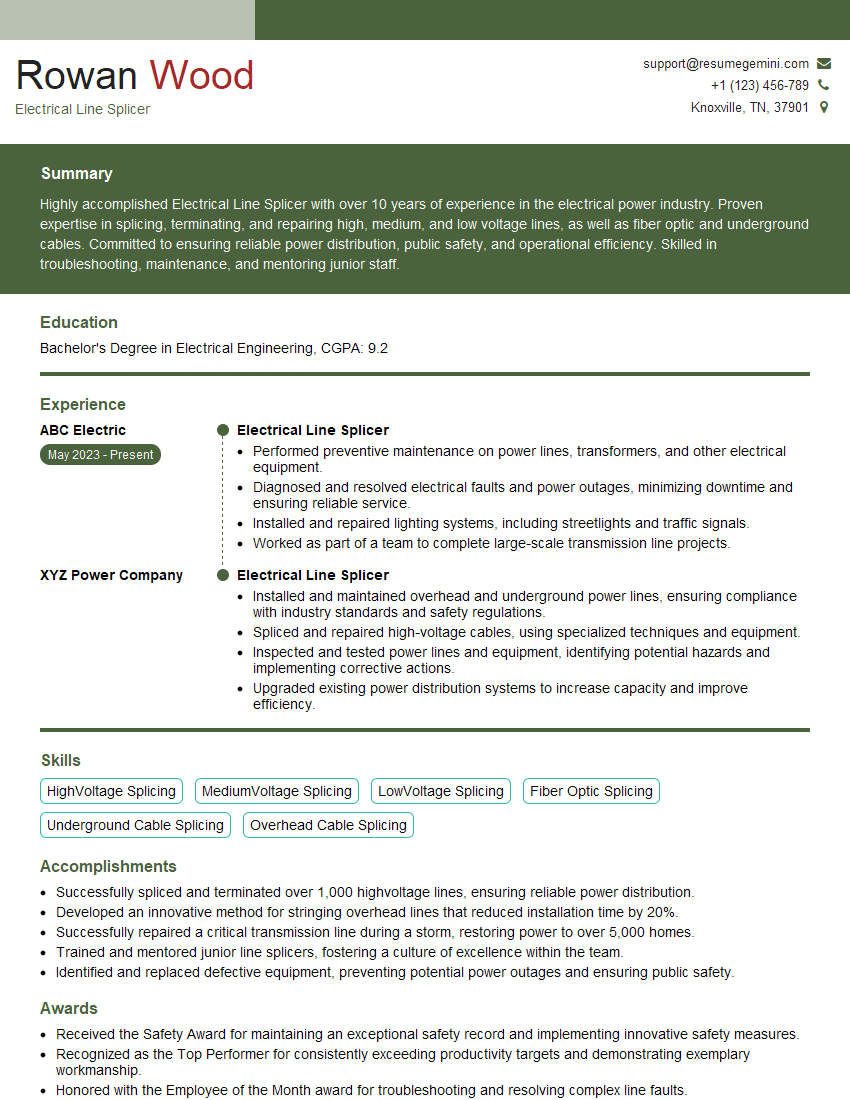

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical Line Splicer

1. What are the different types of electrical cables and their applications?

There are various types of electrical cables, each designed for specific applications. Here are some common types:

- Power cables: Used for transmitting electricity from power sources to distribution points and end users. These cables have high current-carrying capacities.

- Control cables: Used for signal transmission in control systems. They have lower current-carrying capacities and are typically smaller in size.

- Coaxial cables: Used for transmitting high-frequency signals in telecommunications and data transmission. They have a central conductor surrounded by an insulating layer and a conductive shield.

- Fiber optic cables: Used for transmitting data over long distances with minimal signal loss. They use optical fibers to transmit light signals.

- Low-voltage cables: Used for wiring in homes, offices, and other low-voltage applications. These cables have smaller conductors and lower voltage ratings.

2. What are the safety precautions to be taken when working on live electrical lines?

Personal Protective Equipment (PPE)

- Wear insulated gloves

- Wear a hard hat

- Wear safety glasses

- Wear flame-resistant clothing

Worksite Precautions

- Establish a safe work zone

- Use barricades and warning signs

- De-energize lines before working on them (if possible)

- Use insulated tools and equipment

- Maintain a safe distance from live lines

3. What are the different types of splices used in electrical line splicing?

- Western Union splice: A basic splice used for connecting two wires of the same size. It involves twisting the wires together and covering them with solder.

- Brittle splice: Used for splicing wires that are not Twisting the wires together. It involvestwisting the wires together and then solderinga sleeve over the connection.

- Crimp splice: Uses a crimping tool to compress a metal sleeve over the twisted wires, providing a strong and reliable connection.

- Heat-shrink splice: Uses a heat-shrinkable sleeve that is placed over the twisted wires and then heated to shrink, creating a watertight seal.

- Push-in splice: A quick and easy splice that involves inserting the stripped wires into a plastic or spring-loaded connector.

4. What are the steps involved in splicing a high-voltage cable?

- Prepare the cable ends by removing the outer jacket and insulation

- Clean the conductor strands

- Make the splice using the appropriate method (e.g., Western Union splice, heat-shrink splice)

- Insulate the splice with electrical tape or heat-shrink tubing

- Protect the splice with a cable sleeve

- Test the splice for continuity and insulation resistance

5. What is the purpose of using heat-shrink tubing in electrical line splicing?

- Provides insulation and protects the splice from moisture and environmental factors

- Creates a watertight seal, preventing water ingress

- Reinforces the splice, providing mechanical strength and stability

- Identifies the splice location with different colors and markings

- Simplifies the splicing process

6. How do you test the continuity of an electrical line after splicing?

- Use a multimeter set to the ohms setting

- Connect the multimeter probes to the ends of the line

- Read the resistance value on the meter

- A low resistance value (close to zero) indicates continuity

- An infinite resistance value indicates an open circuit or break in the line

7. What are the common problems encountered during electrical line splicing and how do you troubleshoot them?

- Poor insulation: Test the insulation resistance and apply additional insulation if necessary.

- Loose connections: Ensure that all connections are tight and secure.

- Corrosion: Clean and protect the splice from moisture.

- Mechanical damage: Inspect the splice for any damage and repair or replace as needed.

- Overheating: Check for proper wire sizing and ensure there is adequate ventilation.

8. What are the latest advancements in electrical line splicing technology?

- Pre-insulated splice connectors: Simplify the splicing process and reduce the risk of insulation errors.

- Cold welding: A technique that creates a permanent, solderless connection without the use of heat.

- Fiber optic splicing: Used for splicing fiber optic cables, allowing for high-speed data transmission.

- Smart splices: Incorporate sensors and electronics to monitor the health and performance of the splice.

- Automated splicing machines: Increase efficiency and accuracy in splicing operations.

9. How do you stay up-to-date with the latest industry standards and best practices for electrical line splicing?

- Attend industry conferences and training programs

- Read trade publications and technical articles

- Consult with manufacturers and industry experts

- Follow industry organizations and standards bodies

- Participate in continuing education programs

10. What is your experience in working with different types of electrical line splicing equipment?

During my career, I have gained experience using various types of electrical line splicing equipment. Here are some examples:

- Crimping tools (manual and hydraulic)

- Heat guns and heat-shrink ovens

- Insulation testers and multimeters

- Fiber optic splicing machines

- Specialized tools for high-voltage splicing

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical Line Splicer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical Line Splicer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrical Line Splicers play a crucial role in maintaining and repairing electrical distribution and transmission lines. Their key responsibilities include:

1. Cable and Wire Splicing

Splice and repair electrical cables and wires using specialized tools and techniques.

- Install and maintain underground and overhead electrical lines.

- Troubleshoot and repair faults in electrical lines.

2. Equipment Installation and Maintenance

Install and maintain transformers, insulators, switches, and other electrical equipment.

- Perform regular inspections and maintenance checks.

- Replace faulty equipment and components.

3. Safety and Compliance

Adhere to strict safety regulations and industry standards.

- Wear appropriate personal protective equipment (PPE).

- Follow established work procedures and protocols.

4. Communication and Teamwork

Collaborate with other team members and stakeholders.

- Communicate effectively with customers, supervisors, and engineers.

- Work as part of a team to complete projects safely and efficiently.

Interview Tips

Preparing for an interview for an Electrical Line Splicer position requires careful preparation. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Gather information about the company’s history, culture, and the specific requirements of the position. This will help you tailor your answers to the interviewer’s questions.

- Visit the company’s website and social media pages.

- Read industry publications and articles to stay updated on the latest technologies.

2. Practice Your Answers

Prepare for common interview questions related to your skills, experience, and why you are interested in the position. Practice answering these questions concisely and confidently.

- Use the STAR method (Situation, Task, Action, Result) to структуре your answers.

- Focus on highlighting your relevant skills and experiences.

3. Showcase Your Safety Knowledge

Electrical Line Splicers must prioritize safety. Emphasize your understanding of safety regulations, PPE, and work procedures.

- Discuss specific safety measures you have implemented in previous roles.

- Explain your commitment to adhering to industry standards.

4. Highlight Your Teamwork Abilities

Collaboration is essential for Electrical Line Splicers. Highlight your ability to work effectively as part of a team.

- Share examples of successful team projects you have been involved in.

- Discuss your communication and interpersonal skills.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress professionally, arrive on time, and maintain a positive attitude throughout the interview process.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Electrical Line Splicer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.