Are you gearing up for a career in Electrical Machinist? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Electrical Machinist and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

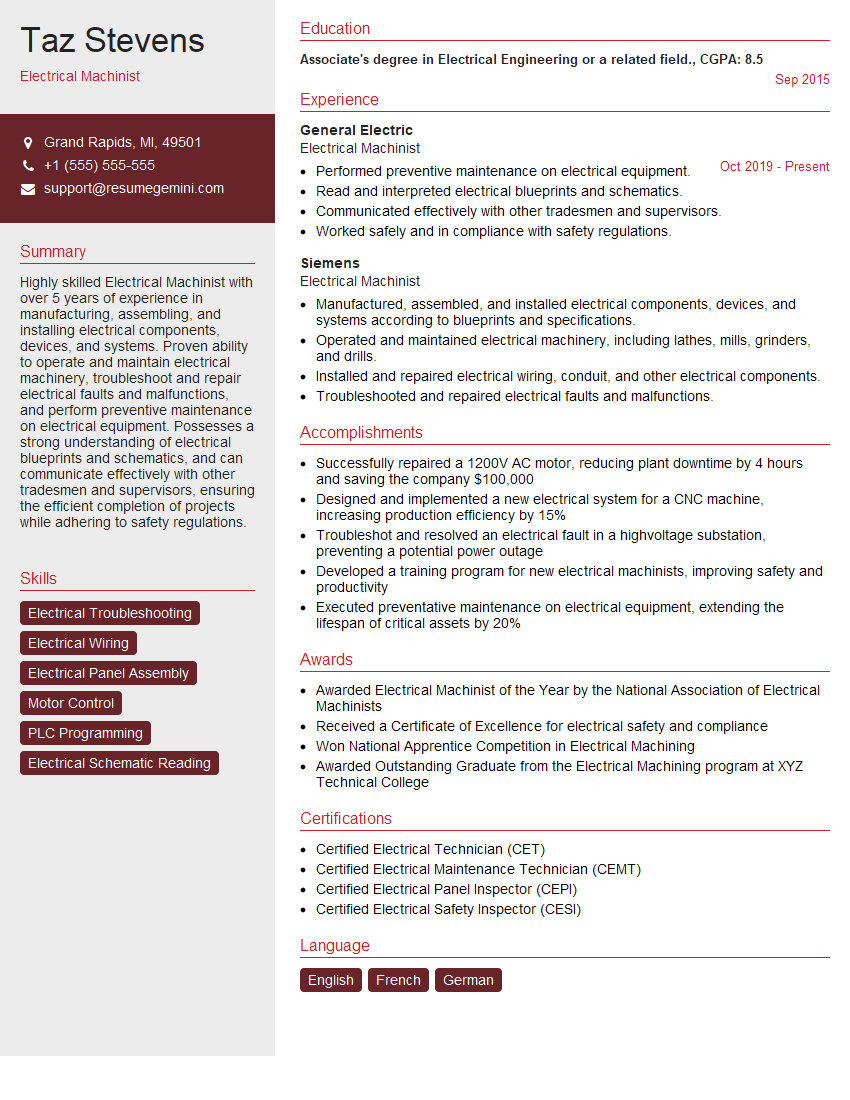

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical Machinist

1. Describe the process of troubleshooting an electrical motor?

To troubleshoot an electrical motor, the following steps can be taken:

- Inspect the motor: Look for any visible damage, such as loose wires, burnt-out components, or broken parts.

- Test the power supply: Ensure that the motor is receiving the correct voltage and amperage. Use a multimeter to check the voltage and continuity of the power source.

- Check the motor’s windings: Use an ohmmeter to measure the resistance of the motor’s windings. If the resistance is too high or too low, it may indicate a winding fault.

- Check the motor’s bearings: Listen for any unusual noises or vibrations coming from the motor. If the bearings are worn or damaged, they may need to be replaced.

- Check the motor’s brushes: If the motor has brushes, inspect them for wear or damage. Replace the brushes if they are worn down or damaged.

2. Explain the different types of electrical motors and their applications?

AC Motors

- Synchronous motors: Used in applications where constant speed is required, such as generators and clocks.

- Induction motors: Used in a wide variety of applications, such as pumps, fans, and compressors.

DC Motors

- Brushed DC motors: Used in applications where high torque is required, such as power tools and electric vehicles.

- Brushless DC motors: Used in applications where high efficiency and reliability are required, such as drones and medical devices.

3. How do you calculate the power factor of an electrical system?

The power factor (PF) of an electrical system is calculated as the ratio of the real power (P) to the apparent power (S):

- PF = P / S

The real power is the power that is actually used by the load, while the apparent power is the vector sum of the real power and the reactive power (Q).

4. What is the difference between a generator and a motor?

- Generator: Converts mechanical energy into electrical energy.

- Motor: Converts electrical energy into mechanical energy.

Both generators and motors are based on the principle of electromagnetic induction, but they operate in opposite directions.

5. What safety precautions should be taken when working with electrical equipment?

- Always wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and insulating boots.

- Never work on live electrical equipment.

- Always use insulated tools.

- Be aware of the location of electrical hazards, such as overhead power lines and underground cables.

- Follow all lockout/tagout procedures.

6. What is the importance of proper grounding in electrical systems?

Proper grounding in electrical systems is important for the following reasons:

- Protects people and equipment from electrical shock.

- Prevents damage to electrical equipment.

- Provides a path for lightning and other electrical surges to flow to the ground.

7. What are the different types of electrical insulation?

- Solid insulation: Made of materials such as rubber, plastic, or ceramic.

- Liquid insulation: Made of materials such as oil or transformer fluid.

- Gaseous insulation: Made of materials such as sulfur hexafluoride (SF6) or nitrogen.

The type of insulation used in a particular application depends on factors such as the voltage, temperature, and environment.

8. What is the purpose of a transformer?

A transformer is a device that transfers electrical energy from one circuit to another through electromagnetic induction.

- Transformers are used to change the voltage or current of an electrical signal.

- They are also used to isolate circuits from each other.

9. What are the different types of electrical enclosures?

- Indoor enclosures: Designed to protect electrical equipment from dust, dirt, and moisture.

- Outdoor enclosures: Designed to protect electrical equipment from the elements, such as rain, snow, and wind.

- Explosion-proof enclosures: Designed to protect electrical equipment from explosions in hazardous areas.

The type of enclosure used in a particular application depends on the environment in which the electrical equipment will be installed.

10. What are the different types of electrical wiring methods?

- Conduit: A metal or plastic pipe that protects electrical wires and cables.

- Cable tray: A metal or plastic tray that supports and protects electrical cables.

- Raceway: A metal or plastic channel that protects electrical wires and cables.

The type of wiring method used in a particular application depends on factors such as the voltage, current, and environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical Machinist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical Machinist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrical Machinists perform a wide range of duties to ensure that electrical equipment and systems operate efficiently and safely. Their key responsibilities include:

1. Inspecting and Troubleshooting Electrical Equipment

Electrical Machinists inspect and identify faulty electrical equipment, assess the extent of the damage, and troubleshoot the cause of malfunctions. They also monitor equipment performance, identify potential problems, and take preventive measures to ensure optimal operation.

2. Installing, Repairing, and Maintaining Electrical Systems

Electrical Machinists install, repair, and maintain various electrical systems, including generators, motors, transformers, and circuit breakers. They follow blueprints and schematics, and use specialized tools and testing equipment to perform electrical installations, repairs, and replacements.

3. Testing and Calibrating Electrical Equipment

Electrical Machinists perform testing and calibration on electrical equipment to ensure that it meets specific performance standards. They use specialized test equipment to measure voltage, current, resistance, and other electrical parameters, and adjust or replace components as necessary to ensure proper operation.

4. Wiring and Connecting Electrical Components

Electrical Machinists wire and connect electrical components, such as switches, outlets, and fixtures, to ensure proper functioning and safety. They follow electrical codes and regulations, and use appropriate wiring techniques and materials.

Interview Tips

Preparing for an interview for an Electrical Machinist position requires thorough research, practice, and confidence. Here are some tips to help you successfully navigate the interview process:

1. Researching the Company and the Role

– Visit the company’s website and social media pages to learn about their business, culture, and recent developments.

– Study the job description carefully to understand the specific requirements and qualifications for the role.

2. Practicing Your Answers

– Prepare for common interview questions by researching typical questions and practicing your answers out loud.

– Use the STAR method (Situation, Task, Action, Result) to structure your responses and provide concrete examples of your skills and experience.

3. Highlighting Your Skills and Experience

– Quantify your accomplishments and provide specific examples to demonstrate your contributions to previous projects.

– Emphasize your technical skills, such as proficiency in electrical theory, troubleshooting, and equipment repair.

4. Demonstrating Your Enthusiasm

– Express your passion for the electrical field and your eagerness to contribute to the company’s success.

– Ask thoughtful questions about the role, the company, and the industry to show your interest and engagement.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Electrical Machinist role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.