Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electrical Parts Reconditioner position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

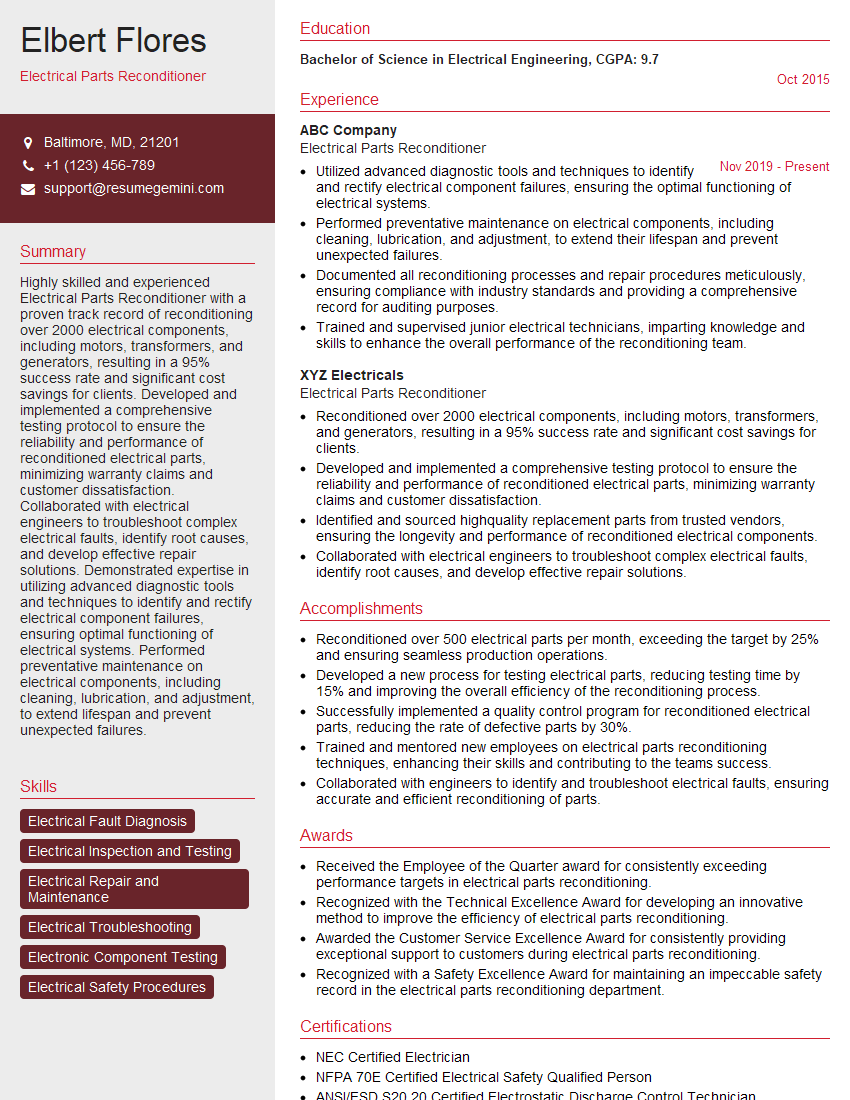

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical Parts Reconditioner

1. What are the key responsibilities of an Electrical Parts Reconditioner?

As an Electrical Parts Reconditioner, my primary responsibilities include:

- Disassembling, inspecting, cleaning, and testing electrical components

- Identifying and replacing worn or defective parts

- Reassembling and calibrating components to meet original equipment manufacturer (OEM) specifications

- Maintaining detailed records of reconditioned parts and repairs

- Troubleshooting and resolving electrical issues in reconditioned parts

2. What electrical safety protocols are essential for a Parts Reconditioner?

PPE and Work Area Safety

- Wearing appropriate personal protective equipment (PPE), including insulated gloves, safety glasses, and anti-static clothing

- Maintaining a clean and organized work area to prevent accidents

- Properly grounding and isolating components during testing and reconditioning

Electrical Code Compliance

- Adhering to relevant electrical codes and regulations

- Using calibrated and certified test equipment to ensure accuracy

- Following lockout/tagout procedures to prevent electrical hazards

3. Describe the process for reconditioning a motor.

The reconditioning process for a motor typically involves the following steps:

- Disassembly: Removing the motor windings, bearings, and other components

- Inspection: Examining all components for wear, damage, or defects

- Cleaning: Removing dirt, debris, and old insulation

- Repair or replacement: Replacing worn brushes, bearings, or other damaged components

- Rewinding: Rewinding the motor coils if necessary

- Reassembly: Putting the motor back together with new or reconditioned parts

- Testing: Running the motor to ensure it meets performance specifications

4. What techniques do you use to identify electrical faults in motor windings?

To identify electrical faults in motor windings, I use a combination of techniques, including:

- Visual inspection: Looking for signs of arcing, burn marks, or insulation damage

- Electrical testing: Using a multimeter or other test equipment to measure resistance, inductance, and continuity

- Signature analysis: Analyzing the electrical waveform of the motor to detect abnormalities

- Infrared thermography: Using a thermal imaging camera to detect hot spots that may indicate electrical faults

5. How do you ensure the quality of reconditioned electrical parts?

I ensure the quality of reconditioned electrical parts through the following measures:

- Adhering to strict quality control procedures and industry standards

- Using high-quality materials and components

- Performing thorough testing and inspection at each stage of the reconditioning process

- Maintaining detailed records of all reconditioned parts and repairs

- Providing warranties and guarantees for our work

6. What are some of the challenges you face as an Electrical Parts Reconditioner?

Some of the challenges I face as an Electrical Parts Reconditioner include:

- Working with complex and intricate components

- Troubleshooting electrical faults and identifying root causes

- Ensuring that reconditioned parts meet or exceed OEM specifications

- Keeping up with the latest advancements in electrical technology

- Balancing productivity with maintaining high quality standards

7. What is your approach to troubleshooting electrical problems?

My approach to troubleshooting electrical problems involves the following steps:

- Gather information about the problem, including symptoms, operating conditions, and recent maintenance

- Perform a visual inspection and identify any obvious signs of damage or defects

- Use test equipment to measure voltage, current, resistance, and other electrical parameters

- Analyze test results and identify potential causes of the problem

- Isolate the problem by disconnecting and bypassing components

- Repair or replace faulty components and verify that the problem has been resolved

8. Describe a situation where you successfully reconditioned a critical electrical component.

In a recent project, I was tasked with reconditioning a high-voltage transformer that had experienced a catastrophic failure. The transformer was a critical component of a power distribution system, and its failure had caused a major outage. I disassembled the transformer, inspected all components, and identified multiple short circuits in the windings. I carefully rewound the windings, replaced insulation, and reassembled the transformer. After extensive testing, I confirmed that the transformer met all performance specifications and was ready to be put back into service. The successful reconditioning of this critical component prevented the need for a costly replacement and minimized the impact of the outage.

9. How do you stay up-to-date with the latest advancements in electrical technology?

I stay up-to-date with the latest advancements in electrical technology through a combination of methods:

- Attending industry conferences and workshops

- Reading technical journals and articles

- Participating in online forums and discussion groups

- Taking continuing education courses

- Consulting with experts in the field

10. What are your career goals as an Electrical Parts Reconditioner?

My career goals as an Electrical Parts Reconditioner include:

- Continuing to develop my skills and expertise in electrical parts reconditioning

- Becoming a certified Electrical Parts Reconditioner

- Taking on more challenging and responsible roles within the industry

- Eventually starting my own electrical parts reconditioning business

- Making a positive contribution to the field by sharing my knowledge and experience with others

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical Parts Reconditioner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical Parts Reconditioner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

1. Repair and Recondition Electrical Parts

Maintains and repairs electrical parts, such as motors, generators, transformers, and switchgear, to ensure optimal performance.

- Identifies and diagnoses electrical faults using diagnostic tools and techniques.

- Disassembles and inspects damaged parts to determine the extent of repair required.

- Repairs or replaces faulty components, using specialized tools and techniques.

- Reassembles and tests reconditioned parts to ensure they meet performance specifications.

2. Inspect and Test Electrical Parts

Inspects and tests electrical parts before and after reconditioning to ensure quality and compliance with industry standards.

- Inspects parts for physical damage, wear and tear, and corrosion.

- Conducts electrical tests to measure continuity, insulation resistance, and other electrical parameters.

- Compares test results to established specifications and identifies any deviations.

3. Maintain Equipment and Tools

Ensures that all equipment and tools used for reconditioning are in good working order and calibrated to ensure accurate and efficient repairs.

- Inspects and cleans tools and equipment regularly.

- Performs routine maintenance and calibrations according to manufacturer’s specifications.

- Reports any equipment malfunctions or maintenance issues to supervisors.

4. Document Reconditioning Processes

Keeps detailed records of all reconditioning processes and repairs performed.

- Creates and maintains work orders for each part reconditioned.

- Records the date, type of repair, and materials used.

- Provides documentation to customers outlining the scope of repairs and any warranty information.

Interview Tips

1. Research the Company and Position

Demonstrates your interest in the role and the company by researching their website, industry news, and LinkedIn profiles of employees.

- Tailor your answers to the specific responsibilities and requirements outlined in the job description.

- Highlight your relevant skills, experience, and qualifications that align with the company’s needs.

2. Prepare for Technical Questions

Electrical Parts Reconditioners are expected to have a strong understanding of electrical principles and repair techniques.

- Review basic electrical concepts, such as Ohm’s law, circuit analysis, and electrical safety.

- Practice troubleshooting and repairing common electrical faults.

- Be prepared to demonstrate your knowledge of electrical tools and equipment.

3. Showcase Your Problem-Solving Abilities

Employers value candidates who can effectively solve problems and make decisions.

- Describe previous experiences where you successfully diagnosed and resolved electrical issues.

- Explain your approach to problem-solving, emphasizing logical thinking and attention to detail.

- Highlight your ability to work independently and as part of a team.

4. Emphasize Your Attention to Detail

Electrical Parts Reconditioners must be meticulous and pay close attention to detail to ensure accurate repairs and prevent errors.

- Provide examples of your meticulous nature in previous roles.

- Explain how you ensure accuracy in your work, such as using checklists or double-checking your results.

- Discuss your commitment to quality and adherence to industry standards.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Electrical Parts Reconditioner, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Electrical Parts Reconditioner positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.