Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electrical Timing Device Calibrator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

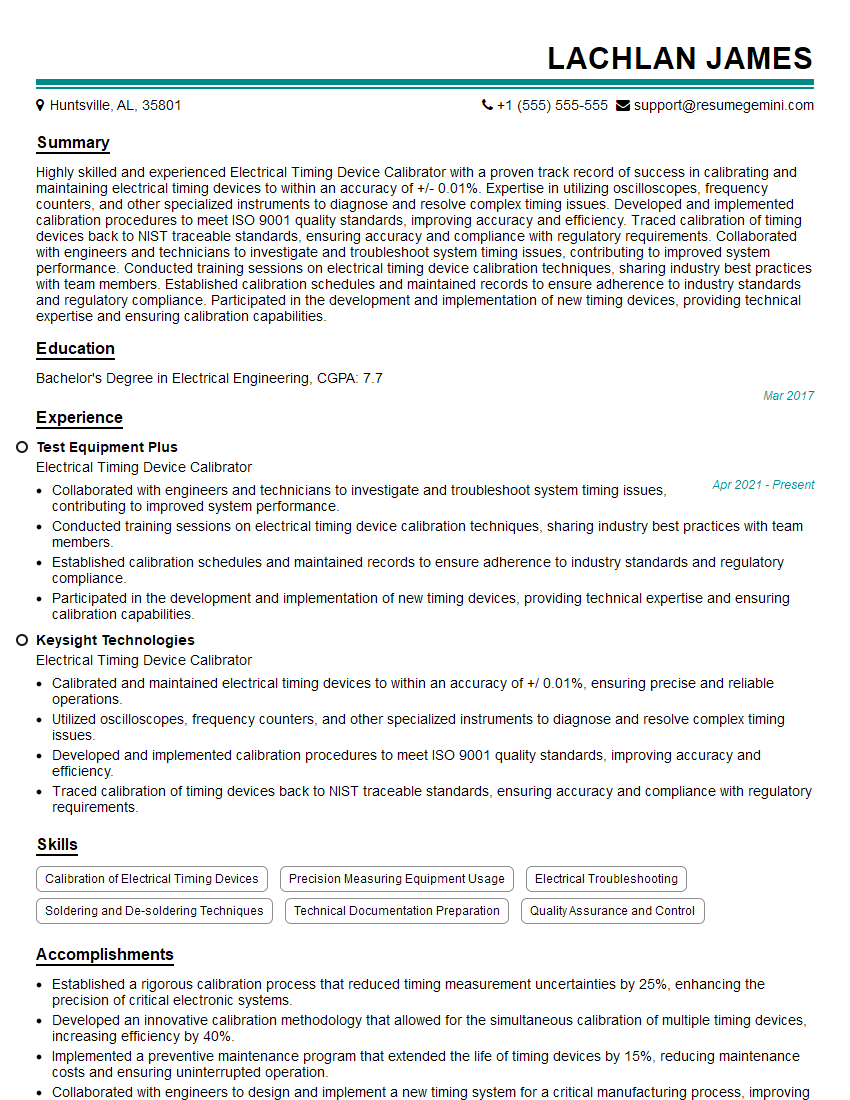

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrical Timing Device Calibrator

1. What are the key considerations when selecting a calibration standard for an electrical timing device?

When selecting a calibration standard for an electrical timing device, several key considerations should be made to ensure accuracy and reliability.

- Traceability: The standard should be traceable to a national or international standard, such as NIST or UKAS, to ensure its accuracy and reliability.

- Stability: The standard should have long-term stability and maintain its calibration over time, minimizing drift and ensuring consistent measurements.

- Accuracy: The standard should have an accuracy that meets or exceeds the requirements of the devices being calibrated to ensure accurate calibration results.

- Range: The standard should cover the range of measurements required for the devices being calibrated to ensure comprehensive testing.

- Cost: The cost of the standard should be considered, balancing accuracy and reliability with affordability.

2. Describe the calibration process for a quartz crystal oscillator.

Calibration Equipment:

- Frequency counter with high resolution and accuracy

- Temperature-controlled chamber

- Calibration software

Calibration Procedure:

- Place the oscillator in the temperature-controlled chamber and stabilize it at the desired temperature.

- Connect the oscillator to the frequency counter and measure its output frequency.

- Compare the measured frequency to the reference frequency and calculate the deviation.

- Adjust the oscillator’s tuning element to minimize the deviation and achieve the desired frequency.

- Repeat steps 2-4 at different temperatures to characterize the oscillator’s frequency stability.

- Generate a calibration certificate documenting the oscillator’s frequency, stability, and any other relevant parameters.

3. What are the common sources of error in electrical timing device calibration?

- Environmental factors: Temperature, humidity, and vibrations can affect the accuracy of timing devices.

- Instrument errors: Errors in the calibration equipment, such as frequency counters or oscilloscopes, can introduce inaccuracies.

- Operator errors: Incorrect connections, improper handling, or misinterpretation of results can lead to calibration errors.

- Device-specific factors: Aging, wear, or damage to the timing device can impact its calibration.

- Reference errors: Inaccurate or unstable reference signals can compromise the calibration accuracy.

4. How do you verify the accuracy of an electrical timing device calibration?

- Cross-check with another calibrated device: Compare the measurements of the device under test with a known accurate timing device.

- Use a traceable calibration standard: Ensure the calibration standard used is traceable to a national or international standard.

- Have the calibration performed by an accredited laboratory: Seek calibration services from laboratories accredited by reputable organizations like ISO/IEC 17025.

- Review the calibration certificate: Verify the certificate thoroughly to ensure it contains all relevant information and meets the required specifications.

- Consider the device’s stability: Account for the device’s stability over time and perform periodic re-calibrations to maintain accuracy.

5. What are the different types of electrical timing devices?

- Quartz crystal oscillators: Highly accurate, stable, and widely used in electronics.

- Atomic clocks: Extremely precise and stable, used in applications requiring exceptional accuracy.

- Digital timers: Electronic devices that measure time intervals using digital circuits.

- Analog timers: Use mechanical or electrical components to measure time intervals.

- Time counters: Measure the number of events occurring within a specific time interval.

6. How do you troubleshoot an electrical timing device that is not functioning properly?

- Check the power supply: Ensure the device is receiving the correct voltage and current.

- Inspect the connections: Verify that all connections are secure and free of corrosion or damage.

- Test the input signal: Confirm that the input signal is within the specified range and format.

- Examine the output signal: Check if the output signal is present and meets the expected specifications.

- Consider environmental factors: Check if the device is operating within its specified temperature and humidity range.

- Look for physical damage: Inspect the device for any signs of damage or wear that may affect its performance.

7. What are the safety precautions to consider when working with electrical timing devices?

- Proper grounding: Ensure all electrical equipment is properly grounded to prevent electrical shocks.

- Use insulated tools: Handle electrical components and connections with insulated tools to avoid accidental contact.

- Follow lockout/tagout procedures: Isolate and de-energize circuits before performing any maintenance or repairs.

- Wear appropriate PPE: Use safety glasses, gloves, and other protective gear when working with electrical devices.

- Be aware of high voltages: Identify and avoid any areas with high voltages, and take necessary precautions.

8. Describe the role of calibration in maintaining the accuracy of electrical timing devices.

- Ensures accuracy: Calibration verifies and adjusts the device’s performance to meet specified accuracy requirements.

- Compensates for drift: Over time, timing devices can experience drift, and calibration compensates for these changes to maintain accuracy.

- Compliance with regulations: Calibration helps meet regulatory requirements and standards that mandate the accuracy of timing devices in certain applications.

- Optimizes performance: Regular calibration optimizes the device’s performance, ensuring it operates at its best and delivers reliable measurements.

- Extends device life: Proper calibration can identify and address issues early on, preventing premature failure and extending the device’s life.

9. How do you interpret the results of an electrical timing device calibration?

- Measurement uncertainty: Review the uncertainty values to determine the level of confidence in the calibration results.

- Traceability: Verify the calibration certificate to ensure the standard used is traceable to a recognized authority.

- Calibration parameters: Note the specific parameters tested, such as frequency, stability, or waveform distortion.

- Pass/fail criteria: Compare the measured values to the specified tolerances to determine if the device meets the required specifications.

- Recommendations: Check for any recommendations provided by the calibration laboratory regarding maintenance or adjustments.

10. What is the importance of using calibrated electrical timing devices in critical applications?

- Accurate measurements: Calibrated devices ensure precise and reliable measurements, which is crucial in applications where accurate timing is essential.

- Safety: In safety-critical systems, accurate timing devices help prevent accidents and malfunctions by ensuring proper timing sequences.

- Reliability: Calibrated devices are more likely to operate reliably and consistently, reducing the risk of downtime and system failures.

- Compliance: Using calibrated devices demonstrates compliance with industry regulations and standards that require accurate timing.

- Quality assurance: Calibrated devices contribute to overall quality assurance by ensuring the accuracy and reliability of measurements and processes.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrical Timing Device Calibrator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrical Timing Device Calibrator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrical Timing Device Calibrators play a crucial role in ensuring the accuracy and reliability of timing devices used in various industries. Their key job responsibilities include:

1. Calibration and Testing

Conduct calibration procedures on a wide range of electrical timing devices, including timers, clocks, and frequency counters.

- Set up and operate calibration equipment.

- Compare device readings to reference standards.

- Adjust and repair devices as necessary.

2. Inspection and Troubleshooting

Inspect timing devices for defects, damage, or improper operation.

- Identify sources of errors or malfunctions.

- Troubleshoot and resolve device issues.

- Document and report on inspection findings.

3. Documentation and Recordkeeping

Prepare and maintain accurate calibration records and reports.

- Record calibration data and device performance.

- Provide written reports on calibration activities.

- Maintain calibration logs and ensure compliance with standards.

4. Quality Assurance

Implement and maintain quality assurance procedures.

- Monitor the accuracy and validity of calibration processes.

- Conduct internal audits and evaluate equipment performance.

- Ensure that all calibrated devices meet industry standards.

Interview Tips

To ace the interview for an Electrical Timing Device Calibrator position, candidates should consider the following preparation tips:

1. Research the Company and Position

Thoroughly research the company and the specific calibration role to demonstrate your interest and understanding of the organization’s needs.

- Review the company website and social media profiles.

- Study the job description and identify key qualifications.

- Prepare questions to ask the interviewer about the company and position.

2. Highlight Relevant Experience and Skills

Emphasize your experience in calibrating electrical timing devices and related equipment.

- Quantify your accomplishments using specific metrics and examples.

- Showcase your ability to troubleshoot and resolve complex calibration issues.

- Demonstrate your knowledge of calibration standards and regulations.

3. Practice Common Interview Questions

Prepare for common interview questions related to calibration, quality assurance, and customer service.

- Explain your calibration process and how you ensure accuracy.

- Describe a challenging calibration project you have encountered and how you resolved it.

- Discuss your approach to quality control and how you handle errors or discrepancies.

4. Show Enthusiasm and Passion

Convey your enthusiasm for the field of calibration and your desire to contribute to the organization’s success.

- Share your interest in the latest advancements in calibration technology.

- Express your commitment to continuous professional development.

- Highlight your passion for delivering high-quality results.

5. Ask Insightful Questions

Prepare thoughtful questions to ask the interviewer about the company, the calibration team, and the industry.

- Inquire about the company’s calibration standards and traceability.

- Ask about the team’s collaboration with other departments.

- Discuss the role of calibration in the organization’s quality management system.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electrical Timing Device Calibrator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!