Feeling lost in a sea of interview questions? Landed that dream interview for Electro Plater but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Electro Plater interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

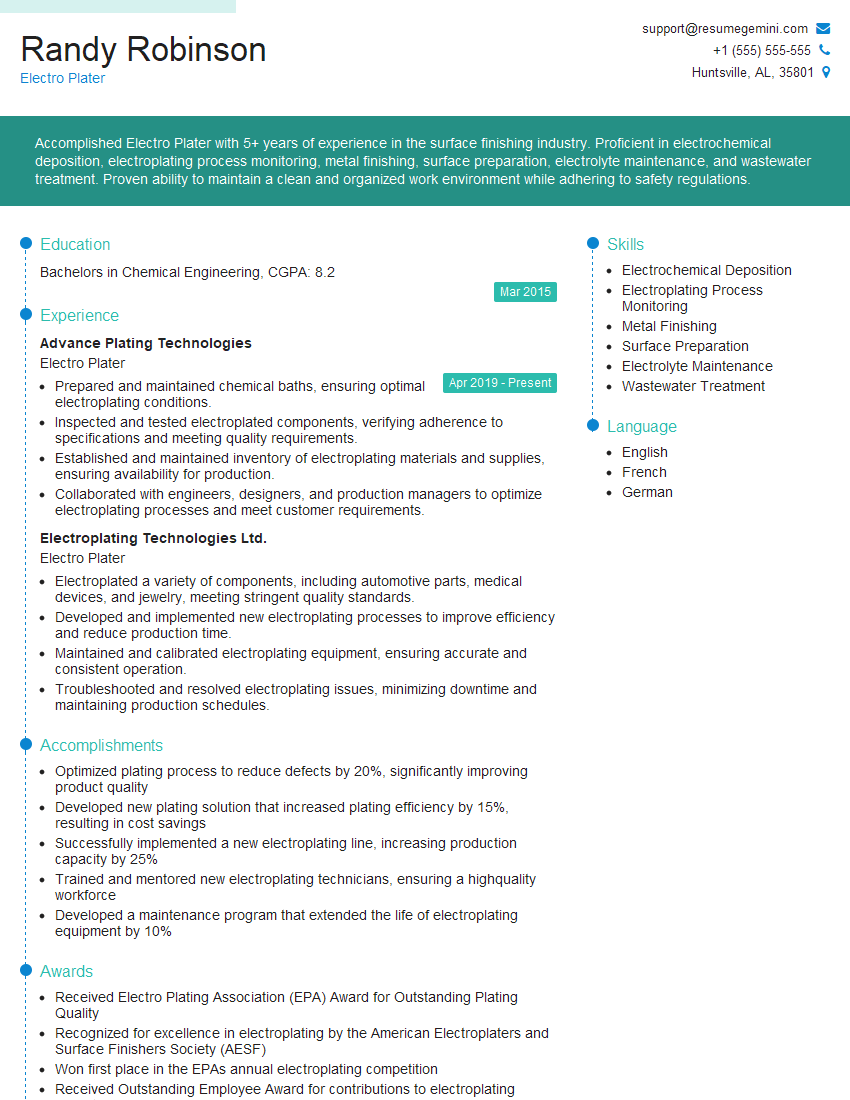

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electro Plater

1. Explain the process of electroplating?

Electroplating is a process of depositing a thin layer of metal onto a conductive surface using an electric current. The process involves immersing the object to be plated in a solution containing the metal ions and connecting it to the negative terminal of a power supply. A metal anode is connected to the positive terminal and immersed in the solution. When the power supply is turned on, electrons flow from the anode to the cathode (the object being plated), reducing the metal ions in the solution and depositing them on the surface of the object.

2. What are the different types of electroplating baths?

Acid baths

- Acid baths contain a high concentration of acid, typically sulfuric acid or hydrochloric acid.

- They are used to deposit metals such as copper, nickel, and chromium.

- Acid baths provide good throwing power and produce bright, shiny deposits.

Alkaline baths

- Alkaline baths contain a high concentration of alkali, typically sodium hydroxide or potassium hydroxide.

- They are used to deposit metals such as zinc, cadmium, and silver.

- Alkaline baths provide good leveling and produce dull, matte deposits.

Neutral baths

- Neutral baths contain a low concentration of acid or alkali.

- They are used to deposit metals such as gold, silver, and platinum.

- Neutral baths provide good throwing power and produce bright, shiny deposits.

3. What are the factors that affect the quality of electroplated coatings?

- The type of metal being deposited

- The concentration of the plating bath

- The temperature of the plating bath

- The current density

- The duration of the plating process

- The surface preparation of the object being plated

4. What are the common defects in electroplated coatings?

- Porosity

- Blistering

- Peeling

- Cracking

- Discoloration

5. What are the safety precautions that should be taken when working with electroplating baths?

- Wear appropriate personal protective equipment, such as gloves, eye protection, and a lab coat.

- Handle chemicals with care and avoid contact with skin and eyes.

- Do not smoke or eat in the plating area.

- Keep the plating area well-ventilated.

- Dispose of waste chemicals properly.

6. What are the applications of electroplating?

- Electroplating is used to protect metals from corrosion.

- It is also used to improve the appearance of metals.

- Electroplating is used in a variety of industries, including automotive, aerospace, and electronics.

7. What are the different types of electroplating equipment?

- Plating tanks

- Power supplies

- Anode baskets

- Cathode racks

- Filters

- Heaters

- Coolers

8. What are the maintenance requirements for electroplating equipment?

- Regularly clean the plating tanks and equipment.

- Check the power supply connections and make sure they are tight.

- Inspect the anode baskets and cathode racks for damage.

- Replace the filters regularly.

- Calibrate the temperature and current controls.

9. How do you troubleshoot problems with electroplating equipment?

- Check the power supply to make sure it is working properly.

- Check the connections between the power supply and the plating tank.

- Check the anode baskets and cathode racks to make sure they are making good contact with the plating solution.

- Check the temperature and current controls to make sure they are set correctly.

- Check the filters to make sure they are not clogged.

10. What are the future trends in electroplating?

- The use of nanotechnology to improve the properties of electroplated coatings

- The development of new environmentally friendly electroplating processes

- The use of electroplating to create new functional materials

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electro Plater.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electro Plater‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electroplaters perform a variety of tasks in order to coat metal surfaces with a thin layer of another metal. This coating can improve the surface’s appearance, corrosion resistance, and conductivity. The key job responsibilities of an Electro Plater include:

1. Operation of electroplating equipment

Electroplaters are responsible for operating a variety of electroplating equipment, including plating tanks, rectifiers, and filters. They must be able to adjust the settings on these machines to achieve the desired results.

2. Preparation of metal surfaces

Before electroplating can be performed, the metal surface must be properly prepared. This involves cleaning the surface to remove any dirt or oil, and then activating the surface to improve the adhesion of the electroplated coating.

3. Electroplating

Electroplating is the process of depositing a thin layer of metal onto a surface using an electric current. Electroplaters must be able to control the current and voltage to achieve the desired thickness and quality of the coating.

4. Inspection and testing

After electroplating, the coated surface must be inspected and tested to ensure that it meets the required specifications. Electroplaters are responsible for performing these tests and making any necessary adjustments to the electroplating process.

Interview Tips

Preparing for an interview can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you prepare for an interview for an Electro Plater position:

1. Research the company and the position

Before you go to an interview, it is important to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and Glassdoor.

2. Practice answering common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as an Electro Plater. Be prepared to discuss your work history, as well as any specific skills or knowledge that you have that would make you a good fit for the position.

4. Be enthusiastic and professional

It is important to be enthusiastic and professional during your interview. This will show the interviewer that you are interested in the position and that you are confident in your abilities. Dress appropriately, arrive on time for your interview, and be polite and respectful to everyone you meet.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electro Plater interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.