Are you gearing up for a career in Electrolysis Engineer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Electrolysis Engineer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

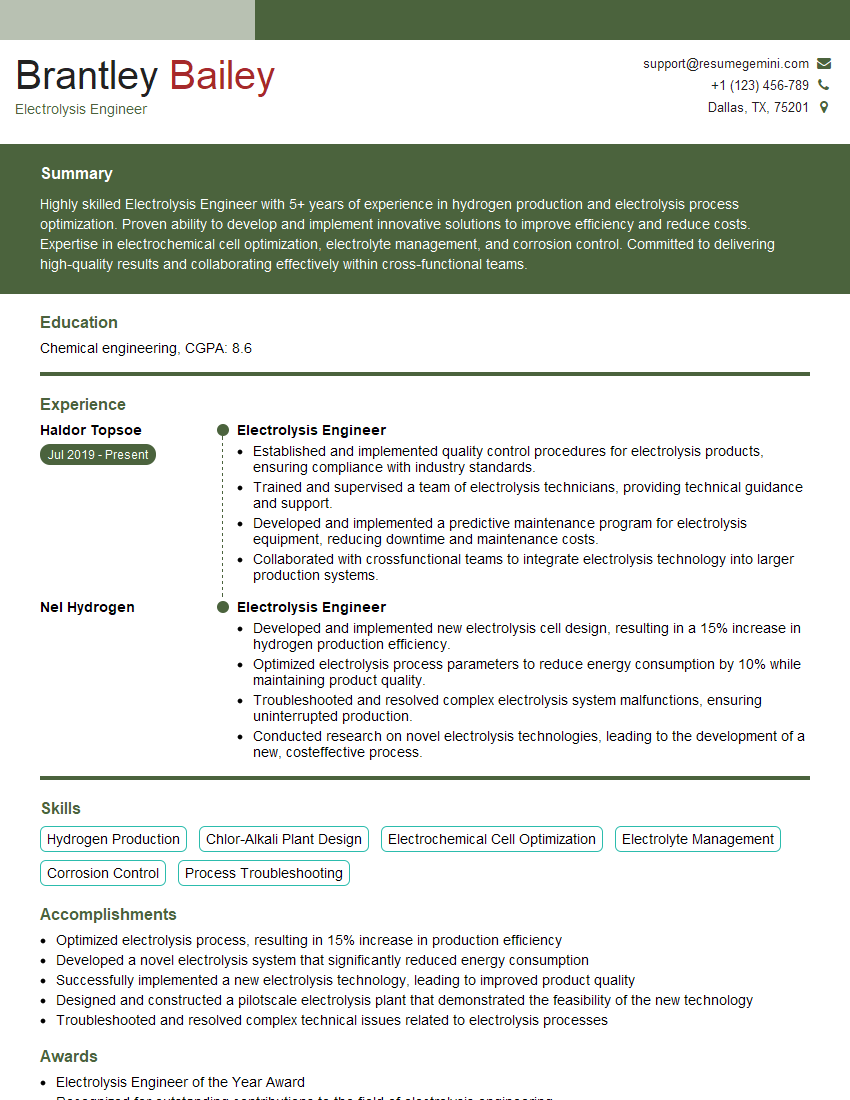

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrolysis Engineer

1. Describe the process of electrolysis and its applications

Electrolysis is a process that uses an electric current to drive a chemical reaction. The electric current is passed through a solution or a molten compound, and the ions in the solution or compound are attracted to the electrodes. The attractions of ions towards the electrodes cause the chemical reaction to occur.

- Electrolysis of water: In the electrolysis of water, the electric current drives the reaction of water molecules into hydrogen and oxygen gases. This process is used to produce hydrogen fuel.

- Electrolysis of brine: In the electrolysis of brine, the electric current drives the reaction of sodium chloride into sodium and chlorine gases. This process is used to produce chlorine for use in water treatment and other industrial processes.

- Electrolysis of aluminum: In the electrolysis of aluminum, the electric current drives the reaction of aluminum oxide into aluminum and oxygen gases. This process is used to produce aluminum for use in a variety of industries.

2. What are the factors that affect the rate of electrolysis?

Concentration of the solution

- The rate of electrolysis increases with increasing the concentration of the solution. This is because a higher concentration of ions means that there are more ions available to be attracted to the electrodes.

Temperature of the solution

- The rate of electrolysis increases with increasing the temperature of the solution. This is because a higher temperature means that the ions have more energy and are more likely to react with the electrodes.

Voltage of the electric current

- The rate of electrolysis increases with increasing the voltage of the electric current. This is because a higher voltage means that there is more energy available to drive the reaction.

Surface area of the electrodes

- The rate of electrolysis increases with increasing the surface area of the electrodes. This is because a larger surface area means that there are more ions that can be attracted to the electrodes.

3. What are the safety precautions that should be taken when working with electrolysis?

Electrolysis can be a hazardous process if proper safety precautions are not taken. Some of the most important safety precautions include:

- Wear appropriate safety gear, such as gloves, eye protection, and a lab coat.

- Work in a well-ventilated area to avoid inhaling harmful gases.

- Do not touch the electrodes or the solution with bare hands.

- Do not use excessive voltage, as this can cause the solution to overheat and splatter.

- Dispose of chemicals properly according to local regulations.

4. What is the difference between electrolysis and electroplating?

Electrolysis and electroplating are both processes that use an electric current to drive a chemical reaction. However, there is a key difference between the two processes.

- Electrolysis is a process that uses an electric current to break down a compound into its constituent elements. For example, electrolysis of water produces hydrogen and oxygen gases.

- Electroplating is a process that uses an electric current to deposit a metal coating on a surface. For example, electroplating is used to deposit a gold coating on jewelry.

5. What are the different types of electrolytic cells?

There are two main types of electrolytic cells:

- Unipolar cells: In unipolar cells, the anode and cathode are made of the same material. This type of cell is used to produce gases, such as hydrogen and oxygen.

- Bipolar cells: In bipolar cells, the anode and cathode are made of different materials. This type of cell is used to produce metals, such as aluminum and copper.

6. What are the advantages and disadvantages of using electrolysis?

Advantages

- Electrolysis is a versatile process that can be used to produce a wide variety of chemicals and materials.

- Electrolysis is a relatively clean process that does not produce harmful emissions.

- Electrolysis can be used to produce high-purity materials.

Disadvantages

- Electrolysis can be an energy-intensive process.

- Electrolysis can produce hazardous gases, such as hydrogen and chlorine.

- Electrolysis can require the use of expensive equipment.

7. What are the emerging applications of electrolysis?

Electrolysis is a rapidly growing field with a wide range of emerging applications. Some of the most promising applications include:

- Production of renewable fuels: Electrolysis can be used to produce hydrogen fuel from water. Hydrogen fuel is a clean-burning fuel that can be used to power vehicles and generate electricity.

- Water desalination: Electrolysis can be used to remove salt from seawater. This process can provide a source of fresh water for communities in arid regions.

- Metal refining: Electrolysis can be used to refine metals such as copper and aluminum. This process can produce high-purity metals that are used in a variety of industries.

8. What are the challenges facing the electrolysis industry?

The electrolysis industry faces a number of challenges, including:

- High energy costs: Electrolysis is an energy-intensive process, and the cost of electricity is a major factor in the cost of producing electrolyzed products.

- Competition from other technologies: Electrolysis competes with other technologies, such as thermal and catalytic processes, for the production of chemicals and materials.

- Environmental concerns: The production of hydrogen fuel from electrolysis can produce greenhouse gases, and the disposal of spent electrolytes can be a challenge.

9. What is your experience with electrolysis?

I have been working with electrolysis for the past 5 years. During that time, I have gained experience in a variety of electrolysis applications, including:

- Production of hydrogen fuel: I have worked on the development of electrolysis systems for the production of hydrogen fuel from water.

- Water desalination: I have worked on the development of electrolysis systems for the desalination of seawater.

- Metal refining: I have worked on the development of electrolysis systems for the refining of metals such as copper and aluminum.

10. What are your career goals?

My career goal is to become a leading expert in the field of electrolysis. I am passionate about the potential of electrolysis to revolutionize the way we produce energy and materials.

- I am particularly interested in the development of new electrolysis technologies that are more efficient and cost-effective.

- I also believe that electrolysis has the potential to play a major role in the development of a sustainable and environmentally friendly economy.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrolysis Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrolysis Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrolysis Engineers are responsible for the design, development, and operation of electrolysis systems. They work to improve the efficiency and effectiveness of these systems, and to develop new applications for them. Some of the key job responsibilities of Electrolysis Engineers include:

1. Design and development of electrolysis systems

Electrolysis Engineers design and develop electrolysis systems for a variety of applications, including the production of hydrogen, chlorine, and other chemicals. They work to optimize the design of these systems to improve their efficiency and effectiveness.

- Design and develop new electrolysis systems

- Improve the efficiency and effectiveness of existing electrolysis systems

- Develop new applications for electrolysis systems

2. Operation and maintenance of electrolysis systems

Electrolysis Engineers operate and maintain electrolysis systems to ensure that they are operating safely and efficiently. They monitor the systems for any problems and perform maintenance as needed.

- Operate and maintain electrolysis systems

- Monitor electrolysis systems for any problems

- Perform maintenance on electrolysis systems as needed

3. Troubleshooting and repair of electrolysis systems

Electrolysis Engineers troubleshoot and repair electrolysis systems when they experience problems. They identify the source of the problem and make the necessary repairs to get the system back up and running.

- Troubleshoot and repair electrolysis systems

- Identify the source of the problem

- Make the necessary repairs to get the system back up and running

4. Research and development of new electrolysis technologies

Electrolysis Engineers conduct research and development to improve the efficiency and effectiveness of electrolysis systems. They work to develop new electrolysis technologies and to find new applications for them.

- Conduct research and development to improve the efficiency and effectiveness of electrolysis systems

- Develop new electrolysis technologies

- Find new applications for electrolysis systems

Interview Tips

To ace the interview for an Electrolysis Engineer position, it is important to be prepared and to have a good understanding of the job requirements. Here are a few tips to help you prepare for the interview:

1. Research the company and the position

Before the interview, take some time to research the company and the position you are applying for. This will help you to understand the company’s culture and the specific requirements of the job. You can find information about the company on their website, in their annual reports, and in news articles. You can also find information about the position in the job description.

- Visit the company’s website

- Read the company’s annual reports

- Read news articles about the company

- Review the job description

2. Practice answering common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

- Prepare answers to common interview questions

- Practice answering these questions in advance

- Deliver your answers confidently and clearly

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills, so be prepared to talk about them in detail. Highlight your experience in electrolysis engineering and your skills in design, development, operation, and maintenance of electrolysis systems.

- Be prepared to talk about your experience in electrolysis engineering

- Highlight your skills in design, development, operation, and maintenance of electrolysis systems

- Provide specific examples of your work

4. Ask questions

At the end of the interview, be sure to ask the interviewer questions about the company and the position. This shows that you are interested in the job and that you are eager to learn more about it.

- Ask questions about the company

- Ask questions about the position

- Show that you are interested in the job

- Show that you are eager to learn more about it

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Electrolysis Engineer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Electrolysis Engineer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.