Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Electrolytic Etcher interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Electrolytic Etcher so you can tailor your answers to impress potential employers.

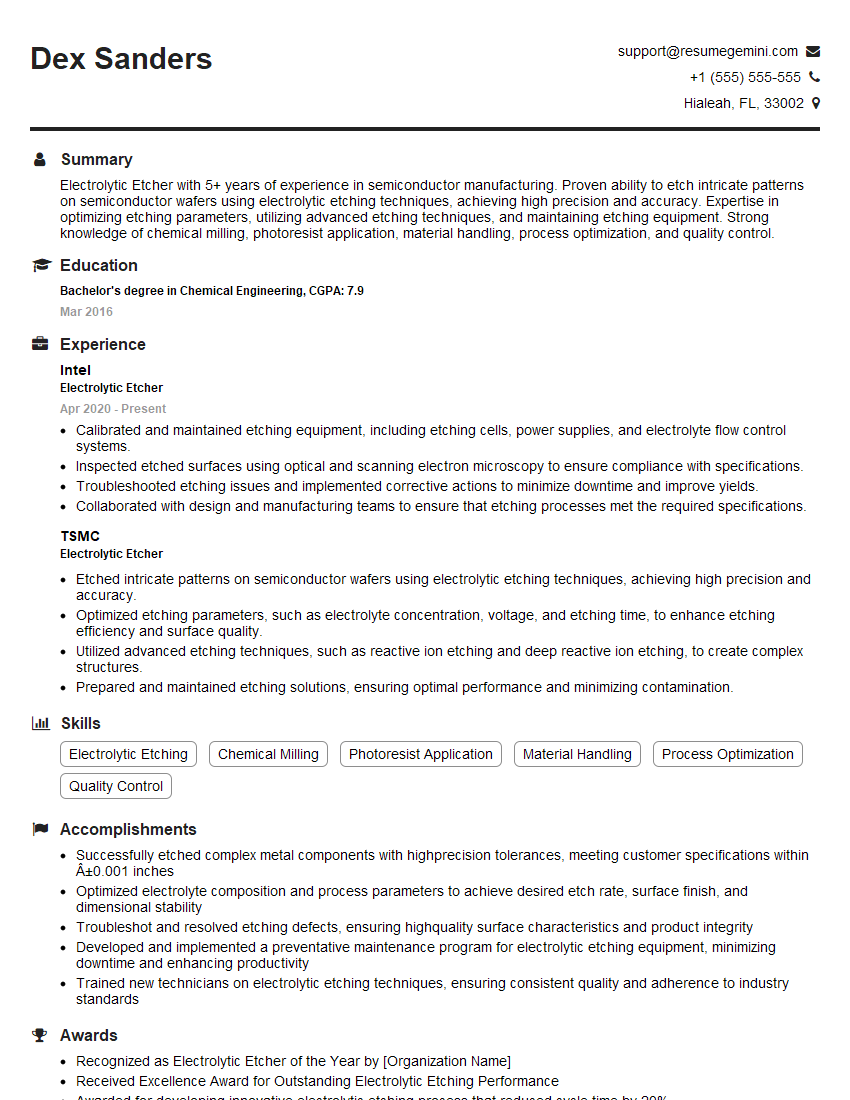

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrolytic Etcher

1. Explain the process of electrolytic etching in detail.

Electrolytic etching is an electrochemical process used to remove material from a metal surface using an electrolytic cell. The process involves immersing the metal in an electrolyte solution and passing an electric current through the solution. The electric current causes the metal to dissolve into the electrolyte solution, creating a recess or cavity in the metal surface.

- The electrolytic etching process can be used to create a variety of features on a metal surface, including:

- Holes

- Slots

- Grooves

- Patterns

- The process is highly controllable, and the depth and width of the etched features can be precisely controlled by varying the voltage and current applied to the electrolytic cell.

2. What are the different types of electrolytes used in electrolytic etching?

Acids:

- Sulfuric acid

- Hydrochloric acid

- Nitric acid

Bases:

- Sodium hydroxide

- Potassium hydroxide

- Sodium carbonate

Salts:

- Sodium chloride

- Potassium chloride

- Magnesium sulfate

3. What are the factors that affect the rate of electrolytic etching?

- Voltage

- Current

- Electrolyte concentration

- Temperature

- Metal type

4. What are the advantages of electrolytic etching?

- High precision

- Controllable depth and width of etched features

- Can be used on a variety of metals

- Relatively low cost

5. What are the disadvantages of electrolytic etching?

- Can produce hazardous waste

- Requires specialized equipment

- Can be time-consuming

6. What are some of the applications of electrolytic etching?

- Creating nameplates and labels

- Etching patterns on jewelry and other decorative items

- Creating molds and dies

- Deburring and polishing metal parts

7. What are the safety precautions that must be taken when performing electrolytic etching?

- Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat.

- Work in a well-ventilated area.

- Handle chemicals with care.

- Dispose of waste properly.

8. What are some of the challenges you have faced in your previous role as an electrolytic etcher?

One of the biggest challenges I faced in my previous role as an electrolytic etcher was maintaining the precision of the etched features. The process is highly sensitive to a number of factors, including the voltage, current, electrolyte concentration, and temperature. Any slight variation in these parameters can result in variations in the depth and width of the etched features.

Another challenge was dealing with the hazardous waste produced by the process. The electrolyte solutions used in electrolytic etching can contain harmful chemicals, and it is important to dispose of them properly. I worked closely with our environmental health and safety department to ensure that all waste was disposed of in accordance with applicable regulations.

9. What are your strengths and weaknesses as an electrolytic etcher?

Strengths:

- Strong understanding of the electrolytic etching process

- Excellent attention to detail

- Proven ability to produce high-quality etched features

- Experience with a variety of metals and electrolytes

Weaknesses:

- Limited experience with large-scale etching projects

- Not familiar with all of the latest electrolytic etching technologies

10. Why are you interested in this position?

I am interested in this position because it offers an opportunity to use my skills and experience in electrolytic etching to contribute to a world-class manufacturing operation. I am particularly interested in the company’s focus on innovation and its commitment to producing high-quality products. I believe that my skills and experience would be a valuable asset to your team, and I am eager to learn more about the position and the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrolytic Etcher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrolytic Etcher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrolytic Etchers are responsible for preparing and etching metal surfaces using electrochemical processes. Their primary duties include:

1. Prepare Workpieces

Clean and degrease metal surfaces to remove contaminants.

- Mask off areas of the workpiece that should not be etched.

2. Create and Maintain Electrolyte Solution

Prepare and maintain the electrolyte solution used in the etching process.

- Monitor the solution’s pH and conductivity levels.

3. Set Up and Operate Etching Equipment

Set up and operate electrolytic etching equipment.

- Control the current, voltage, and temperature of the etching process.

4. Monitor Etching Process

Monitor the etching process to ensure it is proceeding correctly.

- Make adjustments to the process parameters as needed.

- Check the etched surfaces for defects.

5. Clean Up and Maintenance

Clean up the etching area and maintain the etching equipment.

- Dispose of spent electrolyte solution properly.

Interview Tips

To ace an interview for an Electrolytic Etcher position, follow these tips:

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for.

- This will show the interviewer that you are interested in the company and the role.

- It will also help you to answer questions about the company and the position in a more informed way.

2. Prepare for Technical Questions

Expect to be asked technical questions about electrolytic etching during the interview.

- Be prepared to discuss your experience with different types of electrolytic etching equipment and processes.

- You should also be able to answer questions about the safety precautions that must be taken when working with electrolytic etching equipment.

3. Highlight Your Problem-Solving Skills

Electrolytic etching can be a complex process, so interviewers will be looking for candidates who can demonstrate strong problem-solving skills.

- In your interview, be prepared to give examples of times when you have successfully solved problems related to electrolytic etching.

4. Be Enthusiastic and Professional

As with any job interview, it is important to be enthusiastic and professional during your interview for an Electrolytic Etcher position.

- Dress appropriately, arrive on time for your interview, and be prepared to answer questions about your experience and qualifications.

- By showing the interviewer that you are enthusiastic about the position and the company, you will increase your chances of getting hired.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electrolytic Etcher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!