Feeling lost in a sea of interview questions? Landed that dream interview for Electromechanical Assembler but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Electromechanical Assembler interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

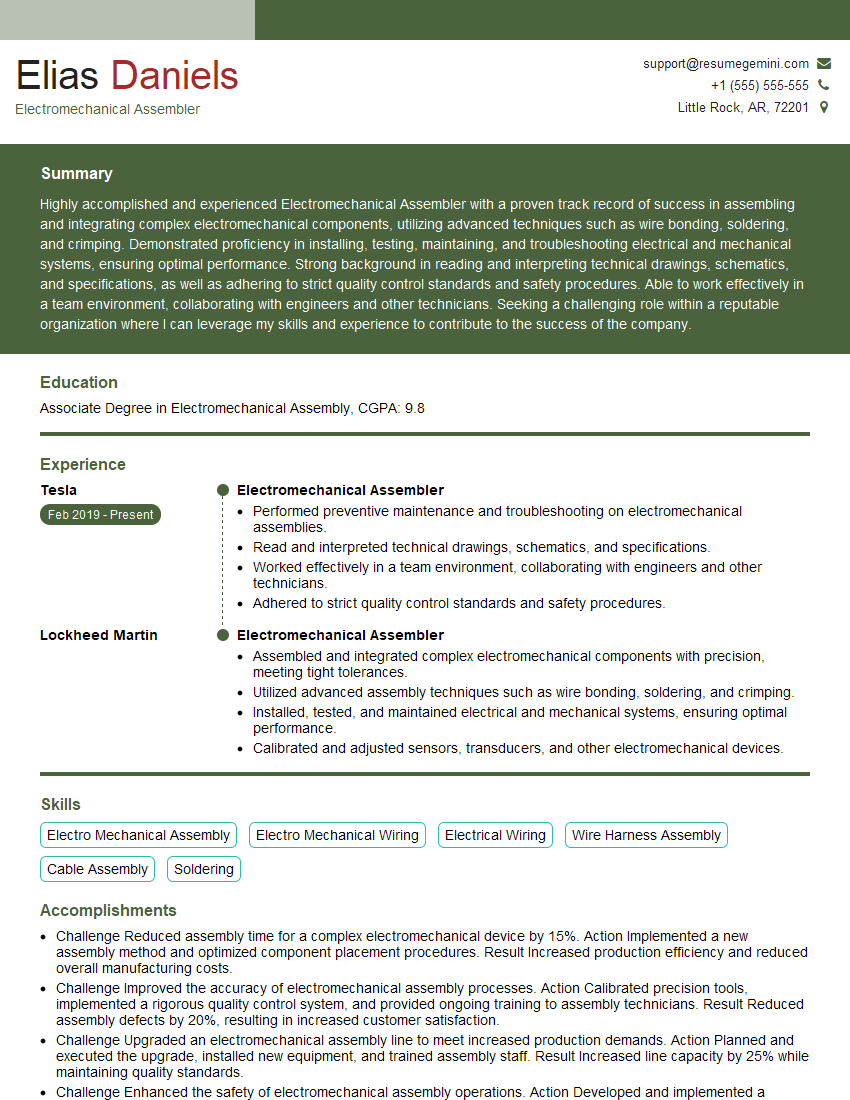

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electromechanical Assembler

1. How do you ensure that the electromechanical assemblies meet the specified requirements and tolerances?

In order to ensure that the electromechanical assemblies meet the specified requirements and tolerances, I follow a meticulous process that involves:

- Thorough Inspection of Components: I begin by meticulously inspecting each individual component to verify its compliance with the technical specifications and drawings.

- Precise Assembly and Calibration: I meticulously assemble the components in strict accordance with the assembly instructions, ensuring that all connections are secure and that the tolerances are met using precision measuring instruments.

- Comprehensive Testing and Validation: Once the assembly is complete, I conduct a series of comprehensive tests to validate its functionality, performance, and adherence to the specified requirements. This includes electrical, mechanical, and environmental testing.

- Continuous Monitoring and Adjustment: Throughout the assembly process, I continuously monitor the assembly’s progress and make necessary adjustments to ensure that it meets the desired specifications. I document all measurements taken and adjustments made for traceability.

2. What is your approach to troubleshooting and resolving issues in electromechanical systems?

Problem Identification and Analysis

- I carefully observe the system’s behavior and identify any deviations from normal operation.

- I analyze the system’s components, wiring, and software to determine the potential cause of the issue.

Solution Implementation

- Based on my analysis, I develop a plan to resolve the issue.

- I implement the solution, which may involve repairing or replacing components, adjusting settings, or updating software.

Testing and Verification

- After implementing the solution, I thoroughly test the system to ensure that the issue has been resolved.

- I verify that the system is operating as expected and meets the required specifications.

Documentation and Follow-up

3. How do you stay updated with the latest advancements in electromechanical assembly techniques and technologies?

To keep abreast of the latest advancements in electromechanical assembly techniques and technologies, I:

- Attend Industry Conferences and Workshops: I actively participate in industry conferences and workshops to learn about new products, technologies, and best practices.

- Read Technical Publications: I regularly read technical journals, white papers, and application notes to stay informed about emerging trends and developments.

- Engage in Online Learning: I take online courses and tutorials to enhance my knowledge and skills in specific areas of electromechanical assembly.

- Network with Professionals: I connect with other electromechanical assemblers and engineers through professional organizations and LinkedIn to share knowledge and learn from their experiences.

4. Can you describe your experience in working with different types of electromechanical components, such as sensors, actuators, and motors?

Throughout my career, I have worked extensively with a wide range of electromechanical components, including:

- Sensors: I have experience in installing, calibrating, and troubleshooting various types of sensors, such as temperature sensors, pressure sensors, and proximity sensors.

- Actuators: I am proficient in working with linear actuators, rotary actuators, and stepper motors. I have experience in integrating them into electromechanical systems and ensuring their proper operation.

- Motors: I have a strong understanding of different types of motors, including DC motors, AC motors, and servo motors. I am skilled in wiring, controlling, and troubleshooting motor systems.

5. What software and tools are you proficient in using for electromechanical assembly and testing?

I am proficient in using various software and tools for electromechanical assembly and testing, including:

- Computer-Aided Design (CAD) Software: I am proficient in using CAD software such as SolidWorks and AutoCAD to create and modify electromechanical designs.

- Electrical Design Software: I am familiar with electrical design software such as EPLAN and Altium Designer, which I use to design and simulate electrical circuits.

- Testing Equipment: I am skilled in using various test equipment, including oscilloscopes, multimeters, and power analyzers, to conduct electrical, mechanical, and environmental testing of electromechanical systems.

6. How do you ensure that the electromechanical assemblies are properly documented and maintained?

To ensure proper documentation and maintenance of electromechanical assemblies, I follow these steps:

- Assembly Documentation: I create detailed assembly drawings, schematics, and assembly instructions to document the assembly process and component details.

- Maintenance Records: I maintain comprehensive maintenance records that include inspection reports, repair logs, and calibration certificates.

- Preventive Maintenance: I perform regular preventive maintenance tasks, such as cleaning, lubrication, and testing, to ensure the ongoing reliability and performance of the electromechanical assemblies.

7. What are the safety precautions you observe when working with electromechanical systems?

When working with electromechanical systems, I strictly adhere to the following safety precautions:

- Electrical Safety: I always verify that the power is isolated before working on electrical components. I use appropriate personal protective equipment (PPE), such as insulated gloves and safety glasses.

- Mechanical Safety: I ensure that all moving parts are properly guarded to prevent accidental contact. I use appropriate tools and techniques to handle and move heavy components.

- Environmental Safety: I am aware of the potential hazards associated with hazardous materials, such as lead and solvents. I take appropriate measures to protect myself and the environment.

8. Can you describe a complex electromechanical assembly project that you have worked on and the challenges you encountered?

One of the most complex electromechanical assembly projects I worked on was the development of a robotic arm for a manufacturing application. The challenges I encountered included:

- Precise Assembly: Ensuring the precise assembly and alignment of multiple mechanical components to achieve accurate and repeatable movements.

- Electrical Integration: Integrating various electrical components, including sensors, actuators, and controllers, to enable seamless communication and control.

- Testing and Validation: Conducting rigorous testing and validation to ensure the robotic arm met the performance and safety requirements of the application.

9. What is your approach to quality control in electromechanical assembly?

I implement a comprehensive quality control approach in electromechanical assembly, which includes:

- Inspection and Verification: I thoroughly inspect all incoming components to ensure they meet specifications. I also verify the assembly process at each stage to identify any potential defects.

- Testing and Validation: I perform rigorous testing and validation procedures to ensure the assembled systems meet the required performance and functional requirements.

- Continuous Improvement: I actively seek opportunities to improve the assembly process and identify areas for optimization. I implement corrective and preventive actions based on quality control data.

10. How do you handle working under pressure and meeting tight deadlines in an electromechanical assembly environment?

In an electromechanical assembly environment with tight deadlines, I manage pressure by:

- Prioritizing Tasks: I prioritize tasks based on their importance and urgency to ensure that critical tasks are completed first.

- Time Management: I effectively manage my time and utilize efficient work practices to optimize productivity and meet deadlines.

- Communication: I maintain open communication with team members and supervisors to keep them informed of my progress and any challenges encountered.

- Stress Management: I practice stress management techniques to maintain focus and composure under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electromechanical Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electromechanical Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Electromechanical Assembler combines electrical components, mechanical parts, and subassemblies to create complex electromechanical systems. They are responsible for ensuring that all components are properly assembled and that the finished product meets the required specifications.

1. Component and subassembly preparation:

Prepares components, subassemblies, and materials for assembly by cleaning and inspecting parts.

- Verifies the accuracy and completeness of parts and materials.

- Assembles and installs electrical and mechanical components according to engineering drawings and specifications.

- Tests assembled electromechanical systems to ensure proper operation.

2. System Assembly:

Assembles electromechanical systems according to specifications and blueprints.

- Installs and connects electrical and mechanical components, such as motors, sensors, controllers, and wiring.

- Performs mechanical assembly tasks, such as drilling, tapping, and fastening.

3. Wiring and electrical installation:

Installs and connects electrical wiring and components according to electrical schematics.

- Solders and crimps wires and terminals to connect electrical components.

- Inspects and tests electrical wiring and components to ensure proper functionality.

4. Testing and troubleshooting:

Conducts tests to ensure that electromechanical systems meet specifications.

- Troubleshoots and repairs malfunctioning systems.

- Calibrates and adjusts systems to ensure optimal performance.

Interview Tips

Preparing thoroughly for an Electromechanical Assembler interview can significantly increase your chances of success. Here are some tips to help you prepare:

1. Research the company and the position:

Familiarize yourself with the company’s background, products or services, and industry. Research the specific role you are applying for and understand its responsibilities and requirements.

- Visit the company’s website, LinkedIn page, and other online resources.

- Read industry news and articles to stay updated on the latest trends and developments.

2. Highlight your skills and experience:

Emphasize your skills and experience in electromechanical assembly, including component preparation, system assembly, wiring, testing, and troubleshooting.

- Quantify your accomplishments and provide specific examples of projects you have worked on.

- Use technical terms and industry jargon to demonstrate your knowledge and expertise.

3. Prepare for common interview questions:

Practice answering common interview questions, such as “Tell me about yourself,” “Why are you interested in this position,” and “Describe your experience in electromechanical assembly.”

- Prepare concise and well-rehearsed answers that highlight your qualifications.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers.

4. Practice your technical skills:

Review basic electrical and mechanical principles and brush up on your knowledge of tools and equipment used in electromechanical assembly.

- Consider taking online courses or workshops to refresh your technical skills.

- Practice soldering, wiring, and other technical tasks that are relevant to the position.

5. Dress professionally and arrive on time:

First impressions matter, so dress professionally and arrive for your interview on time. Be polite and respectful to everyone you meet.

- Wear a suit or business casual attire.

- Arrive at the interview location 15 minutes early to allow for unexpected delays.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Electromechanical Assembler, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Electromechanical Assembler positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.