Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electron-Beam Photo Mask Technician position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

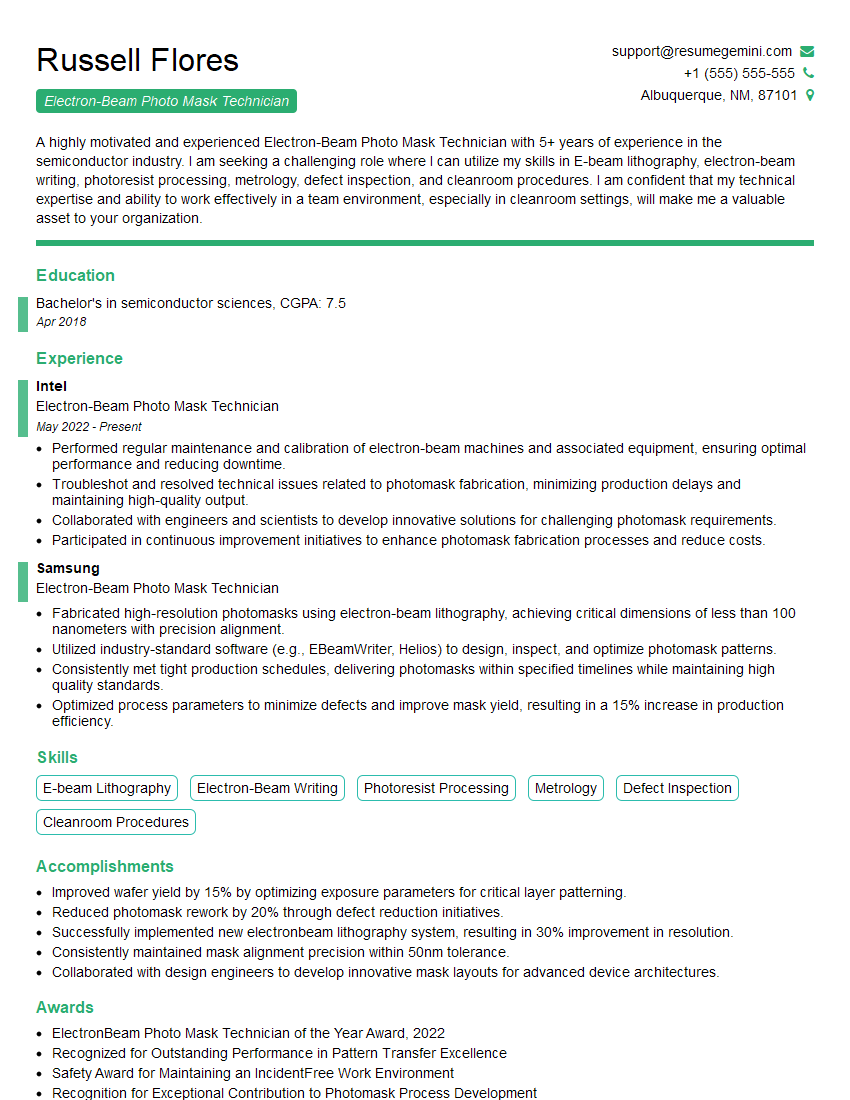

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electron-Beam Photo Mask Technician

1. What are the essential steps involved in fabricating electron-beam photo masks?

The key steps involved in fabricating electron-beam photo masks include:

- Substrate preparation: Cleaning and prepping the glass or quartz substrate to ensure a clean and smooth surface for mask creation.

- Resist coating: Applying a photosensitive resist material onto the substrate, which will be exposed to electron beams and selectively removed during development.

- Pattern generation: Using an electron beam lithography system to expose the resist to a precise pattern of electrons, creating latent images corresponding to the desired circuit design.

- Development: Dissolving and removing the exposed portions of the resist, leaving behind a patterned resist layer that defines the circuit features.

- Etching: Transferring the resist pattern into the underlying substrate using a controlled etching process, creating the desired circuit structures.

- Inspection and metrology: Thoroughly inspecting and measuring the finished mask to ensure accuracy, dimensional compliance, and pattern fidelity.

2. Describe the different types of electron-beam photoresists and their properties.

Positive resists

- Exposed areas become soluble and are removed during development.

- High resolution and good pattern fidelity.

- Examples: PMMA, HSQ

Negative resists

- Exposed areas become cross-linked and remain intact during development.

- Less resolution than positive resists, but thicker resist layers possible.

- Examples: SU-8, SAL601

3. Discuss the factors that can affect the resolution and accuracy of electron-beam patterning.

Factors affecting resolution and accuracy include:

- Electron beam energy and spot size: Higher energy and smaller spot size lead to finer resolution.

- Substrate characteristics: Surface roughness, cleanliness, and thickness can impact pattern fidelity.

- Resist thickness and properties: Thicker resists provide higher aspect ratios but may reduce resolution.

- Exposure dose and development process: Optimizing these parameters is crucial for precise pattern formation.

- Equipment calibration and maintenance: Regular calibration and maintenance of the electron-beam lithography system ensure accuracy.

4. How do you handle and inspect electron-beam photo masks to prevent contamination and damage?

Handling and inspection techniques to prevent contamination and damage:

- Wear gloves and use cleanroom protocols.

- Handle masks by the edges or use vacuum tweezers.

- Inspect masks under controlled lighting and magnification.

- Use non-contact inspection techniques like optical microscopy or laser scanning.

- Store masks in a clean, dry environment with proper humidity control.

5. Describe the role of metrology in electron-beam photo mask fabrication.

Metrology plays a vital role in ensuring the accuracy and quality of electron-beam photo masks:

- Dimensional measurements: Verifying mask dimensions, feature sizes, and placement accuracy.

- Pattern fidelity evaluation: Assessing the sharpness, edge roughness, and overall quality of the patterned features.

- Defect detection: Identifying and classifying defects such as pinholes, scratches, or contamination.

- Process control: Monitoring process parameters and making adjustments to optimize mask fabrication.

6. What are the challenges and emerging trends in electron-beam photo mask technology?

Challenges:

- Achieving higher resolution and accuracy for advanced device fabrication.

- Reducing contamination and defects to meet stringent yield requirements.

- Increasing throughput and efficiency to meet production demands.

Emerging trends:

- Extreme ultraviolet (EUV) lithography: Utilizing shorter wavelengths for even finer resolution.

- Maskless lithography: Direct patterning without the need for physical masks.

- Nanopatterning for advanced materials and devices.

7. How do you stay updated with the latest developments and advancements in electron-beam photo mask technology?

To stay updated, I regularly engage in the following activities:

- Attend industry conferences and workshops.

- Read technical journals and publications.

- Network with experts and professionals in the field.

- Participate in online forums and discussion groups.

- Explore research and development initiatives at universities and research labs.

8. Describe a situation where you successfully resolved a complex technical issue related to electron-beam photo mask fabrication.

In my previous role, we encountered an issue with mask distortion during the development process. I conducted thorough investigations, including metrology measurements, resist characterization, and process parameter analysis. By optimizing the exposure dose and adjusting the developer concentration, I identified and corrected the root cause, resulting in masks with significantly reduced distortion and improved yield.

9. How do you ensure that the fabricated electron-beam photo masks meet the required specifications and quality standards?

To ensure compliance with specifications and quality standards, I implement the following measures:

- Rigorous metrology and inspection procedures to verify dimensional accuracy, pattern fidelity, and defect levels.

- Regular equipment calibration and maintenance to minimize errors and ensure optimal performance.

- Close collaboration with design and process engineers to understand mask requirements and optimize fabrication processes.

- Continuous monitoring of process parameters and implementation of statistical process control techniques.

10. What are your strengths and weaknesses as an Electron-Beam Photo Mask Technician?

Strengths:

- Expertise in electron-beam lithography and mask fabrication.

- Strong understanding of resist chemistry, exposure parameters, and development processes.

- Proficient in metrology and inspection techniques.

- Excellent problem-solving and troubleshooting skills.

Weaknesses:

- Limited experience with extreme ultraviolet (EUV) lithography.

- Seeking opportunities to expand my knowledge of maskless lithography techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electron-Beam Photo Mask Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electron-Beam Photo Mask Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electron-beam photo mask technicians are responsible for the fabrication of photo masks used in the production of semiconductor devices. Their key responsibilities include:

1. Preparing and cleaning substrates

Inspecting, cleaning, and preparing substrates for mask deposition

- Sputtering

- Evaporating

- Electroplating

2. Operating electron-beam lithography systems

Setting up and operating electron-beam lithography systems to write patterns on substrates

- Controlling exposure parameters

- Monitoring system performance

3. Developing and etching masks

Developing and etching masks to create the desired patterns

- Using photoresists

- Using wet and dry etching techniques

4. Inspecting and testing masks

Inspecting and testing masks to ensure they meet specifications

- Using optical and electron microscopes

- Performing electrical tests

Interview Tips

To prepare for an interview for an electron-beam photo mask technician position, candidates should:

1. Research the company and the position

Learn about the company’s products and services, as well as the specific requirements of the position.

- Visit the company’s website

- Read industry publications

- Network with professionals in the field

2. Practice answering common interview questions

Prepare answers to common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”.

- Use the STAR method to answer questions

- Be specific and provide examples

- Practice with a friend or family member

3. Dress professionally and arrive on time

First impressions matter, so dress professionally and arrive on time for your interview.

- Wear a suit or business casual attire

- Be punctual and respectful of the interviewer’s time

- Bring a portfolio of your work

4. Be prepared to ask questions

Asking questions shows that you are interested in the position and the company.

- Ask about the company’s culture

- Ask about the training and development opportunities

- Ask about the company’s future plans

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Electron-Beam Photo Mask Technician role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.