Feeling lost in a sea of interview questions? Landed that dream interview for Electronic Components Insertion Machine Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Electronic Components Insertion Machine Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

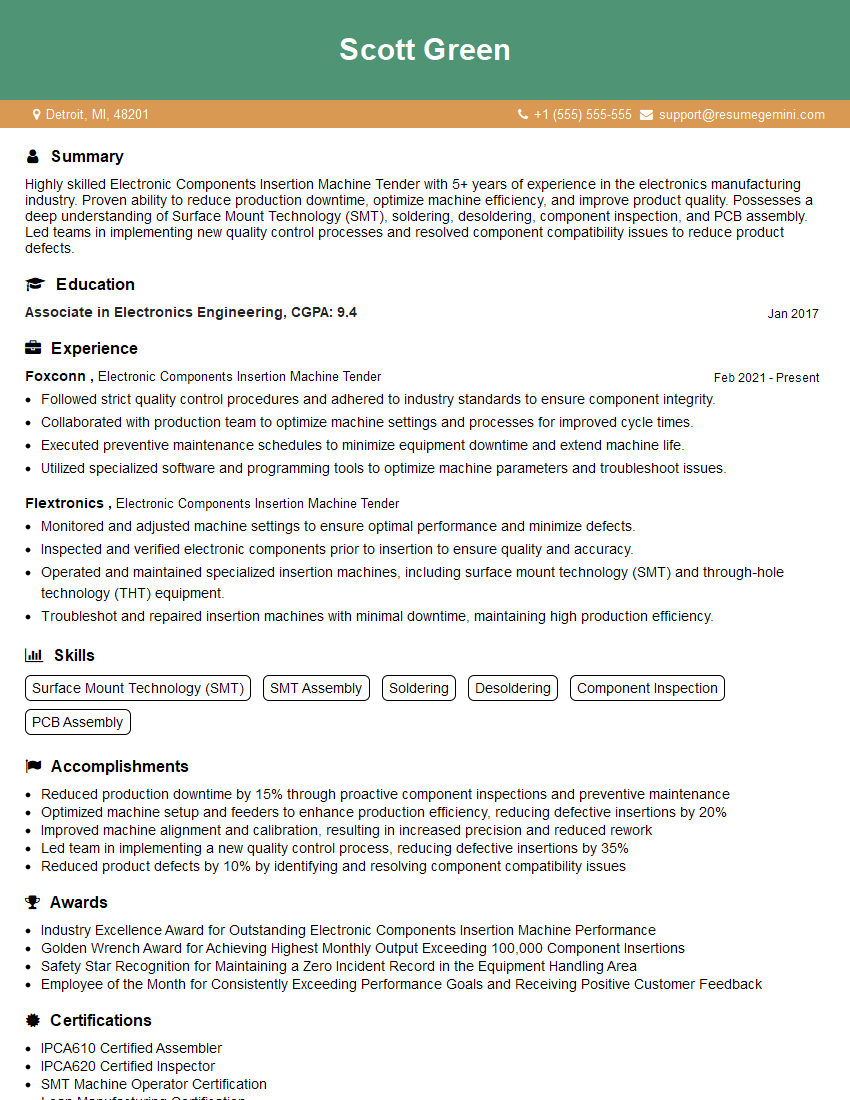

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electronic Components Insertion Machine Tender

1. What are the key responsibilities of an Electronic Components Insertion Machine Tender?

The key responsibilities of an Electronic Components Insertion Machine Tender include:

- Loading and unloading electronic components insertion machines

- Monitoring the operation of machines and making adjustments as needed

- Identifying and correcting defects in electronic components

- Maintaining a clean and organized work area

- Following safety procedures and regulations

2. What are the different types of electronic components insertion machines?

Vacuum Placement Machines

- Use a vacuum to pick up and place components

- Suitable for high-speed, high-volume applications

Mechanical Placement Machines

- Use mechanical grippers to pick up and place components

- Suitable for lower-speed, lower-volume applications

3. What are the key factors to consider when selecting an electronic components insertion machine?

When selecting an electronic components insertion machine, it is important to consider the following factors:

- The type of components to be inserted

- The volume of components to be inserted

- The desired speed and accuracy of the machine

- The available budget

4. How do you troubleshoot an electronic components insertion machine that is not inserting components correctly?

To troubleshoot an electronic components insertion machine that is not inserting components correctly, I would first check the following:

- The power supply to the machine

- The air supply to the machine

- The vacuum system of the machine

- The grippers or nozzles of the machine

- The software of the machine

5. What are the safety precautions that must be taken when operating an electronic components insertion machine?

When operating an electronic components insertion machine, it is important to take the following safety precautions:

- Wear appropriate safety gear, such as safety glasses, gloves, and a lab coat

- Keep long hair and loose clothing away from moving parts

- Do not operate the machine if it is not properly grounded

- Follow all safety instructions provided by the machine manufacturer

6. What are the maintenance procedures that must be performed on an electronic components insertion machine?

The maintenance procedures that must be performed on an electronic components insertion machine include:

- Regularly cleaning and inspecting the machine

- Lubricating moving parts

- Calibrating the machine

- Performing software updates

7. What are the potential hazards associated with working with electronic components insertion machines?

The potential hazards associated with working with electronic components insertion machines include:

- Electrical shock

- Pinch points

- Eye injuries

- Repetitive strain injuries

8. What are the quality control procedures that must be followed when working with electronic components insertion machines?

The quality control procedures that must be followed when working with electronic components insertion machines include:

- Inspecting components before and after insertion

- Testing assembled boards for functionality

- Documenting all quality control procedures

9. What are the training requirements for working with electronic components insertion machines?

The training requirements for working with electronic components insertion machines vary depending on the specific machine and the company’s policies. However, most training programs include the following:

- Safety training

- Machine operation training

- Quality control training

10. What are the career advancement opportunities for Electronic Components Insertion Machine Tenders?

Career advancement opportunities for Electronic Components Insertion Machine Tenders include:

- Supervisor

- Quality control inspector

- Equipment maintenance technician

- Manufacturing engineer

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electronic Components Insertion Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electronic Components Insertion Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electronic Components Insertion Machine Tenders are responsible for setting up, operating, and maintaining computerized machines that insert electronic components onto printed circuit boards.

1. Machine Setup and Operation

Setup and operate electronic components insertion machines according to established procedures and specifications.

- Load printed circuit boards and electronic components into the machine.

- Program the machine to insert the components in the correct locations on the circuit board.

- Monitor the machine’s operation and make adjustments as needed.

- Unload finished circuit boards from the machine.

2. Machine Maintenance

Perform routine maintenance on electronic components insertion machines.

- Clean and lubricate the machine’s components.

- Inspect the machine for wear and tear.

- Replace worn or damaged parts.

- Calibrate the machine.

3. Quality Control

Inspect electronic components and circuit boards for defects.

- Use precision measuring tools to ensure that components are inserted correctly.

- Identify and correct defects in the circuit boards.

4. Troubleshooting

Diagnose and resolve problems with electronic components insertion machines.

- Identify the source of the problem.

- Repair or replace the faulty components.

- Retest the machine to ensure that it is functioning properly.

Interview Tips

Preparing for an interview for an Electronic Components Insertion Machine Tender position requires specific knowledge of the role and effective interview techniques.

1. Research the Company and Position

Thoroughly research the company’s website, industry publications, and social media pages to understand its culture, values, and products/services.

- Identify the specific requirements of the Electronic Components Insertion Machine Tender role and tailor your responses accordingly.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in operating and maintaining electronic components insertion machines.

- Quantify your accomplishments and provide specific examples of successful machine setups, maintenance procedures, and troubleshooting experiences.

- Showcase your understanding of electronic components, printed circuit boards, and quality control standards.

3. Demonstrate Problem-Solving Abilities

Interviews often include situational questions to assess your problem-solving skills.

- Describe a time when you encountered a technical issue with an electronic components insertion machine and how you diagnosed and resolved it.

- Explain how you prioritize tasks and handle multiple projects simultaneously.

4. Articulate Attention to Detail

Electronic Components Insertion Machine Tenders require meticulous attention to detail to ensure accuracy and quality.

- Provide examples of your ability to follow precise instructions, inspect components for defects, and maintain a clean and organized work area.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Electronic Components Insertion Machine Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.