Feeling lost in a sea of interview questions? Landed that dream interview for Electronic Die Maker but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Electronic Die Maker interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

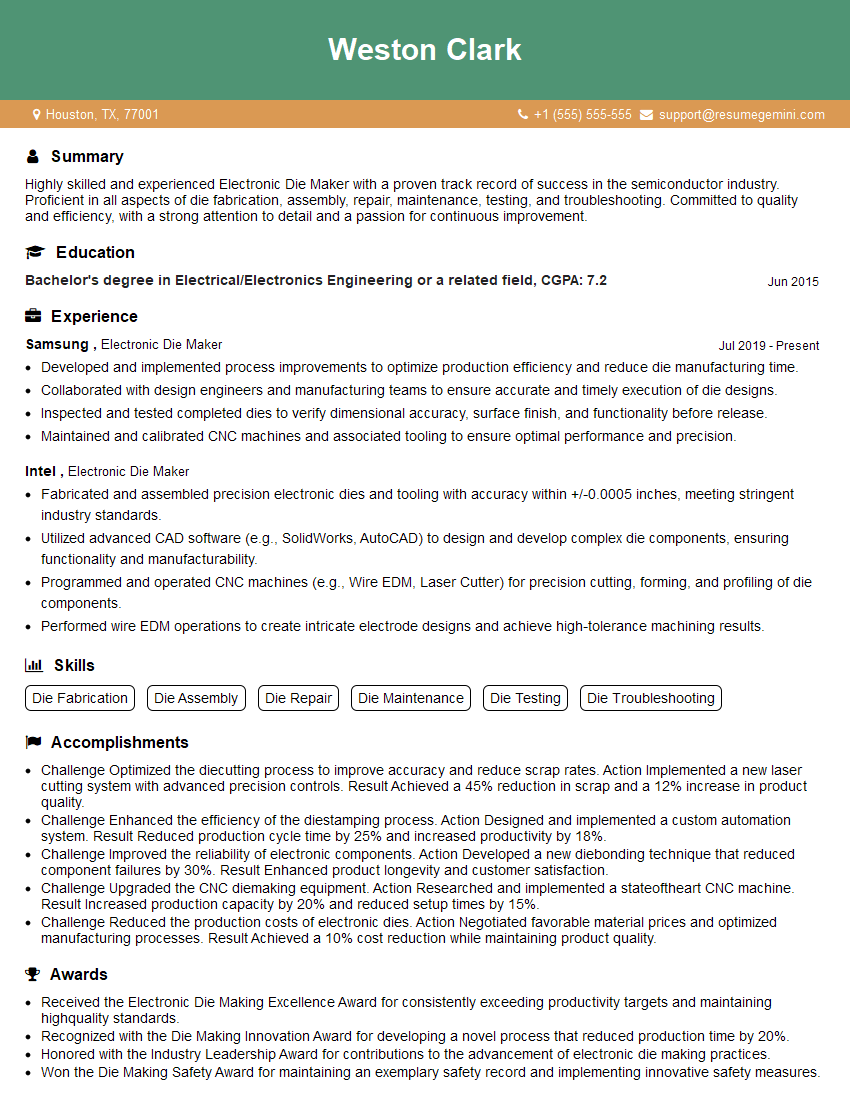

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electronic Die Maker

1. Explain the process of creating an electronic die.

- Start with a design concept and create a 3D model.

- Use computer-aided design (CAD) software to create a 2D layout of the die.

- Transfer the layout to a photomask, which is used to expose a light-sensitive resist on a silicon wafer.

- Develop the resist, which leaves behind a pattern of exposed silicon.

- Etch the exposed silicon to create the die.

2. What are the different types of electronic dies?

- CMOS dies: Used in a wide range of electronic devices, including computers, smartphones, and digital cameras.

- Bipolar dies: Used in high-power applications, such as power amplifiers and voltage regulators.

- GaAs dies: Used in high-frequency applications, such as microwave devices and satellite communications.

3. What are the key factors to consider when designing an electronic die?

- Functionality: The die must perform the desired function.

- Performance: The die must meet the required performance specifications, such as speed, power consumption, and reliability.

- Cost: The die must be manufactured at a cost that is competitive with other products.

4. What are the challenges of electronic die making?

- Precision: Electronic dies must be manufactured with extremely high precision to ensure proper functionality.

- Contamination: The manufacturing process must be controlled to prevent contamination, which can lead to defects.

- Yield: The yield rate of electronic dies is often low, which can increase the cost of production.

5. What are the latest trends in electronic die making?

- 3D dies: 3D dies are used to create more complex and functional devices.

- Advanced packaging: Advanced packaging techniques are used to improve the performance and reliability of electronic dies.

- New materials: New materials are being developed to improve the performance and cost of electronic dies.

6. How do you stay up-to-date on the latest trends in electronic die making?

- Attend industry conferences and exhibitions.

- Read technical journals and articles.

- Network with other professionals in the field.

7. What is your experience with electronic die making?

- I have worked as an electronic die maker for the past 5 years.

- I have experience with a variety of electronic die making processes, including CMOS, bipolar, and GaAs dies.

- I have a strong understanding of the key factors to consider when designing an electronic die.

8. What are your strengths and weaknesses as an electronic die maker?

- Strengths: I am a highly skilled and experienced electronic die maker with a strong understanding of the industry.

- Weaknesses: I am sometimes too detail-oriented, which can slow down the production process.

9. Why are you interested in this job?

- I am interested in this job because it offers me the opportunity to work with a team of experienced professionals on cutting-edge electronic die making projects.

- I am also excited about the opportunity to contribute to the development of new electronic products.

10. What are your salary expectations?

- My salary expectations are in line with the market rate for electronic die makers with my experience and skills.

- I am willing to negotiate a salary that is fair and competitive.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electronic Die Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electronic Die Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electronic Die Makers are responsible for designing, fabricating, and maintaining dies used in the production of electronic components. They work closely with engineers and other manufacturing personnel to ensure that the dies meet the required specifications and produce high-quality products.

1. Die Design

Electronic Die Makers design and develop dies using computer-aided design (CAD) software. They consider factors such as the material properties of the workpiece, the desired product shape, and the manufacturing process to be used.

- Create new die designs or modify existing ones based on engineering specifications.

- Analyze and optimize die designs to ensure they meet production requirements and quality standards.

2. Die Fabrication

Electronic Die Makers fabricate dies using a variety of precision machining techniques. They use machines such as milling machines, lathes, and wire electrical discharge machines (WEDMs) to cut and shape the die components.

- Select appropriate materials and tooling for die fabrication.

- Operate various machining and fabrication equipment to create die components with high precision and accuracy.

3. Die Maintenance

Electronic Die Makers maintain dies to ensure they are in good working condition and produce high-quality products. They perform regular inspections and repairs, and they replace worn or damaged components.

- Conduct routine inspections and maintenance checks on dies to identify any issues or wear.

- Repair or replace damaged or worn die components to ensure optimal performance.

4. Quality Control

Electronic Die Makers play a crucial role in ensuring the quality of the products produced using the dies they create and maintain. They conduct quality control checks on the dies and the products they produce.

- Inspect dies and products to verify adherence to specifications and quality standards.

- Identify and address any quality issues or defects to maintain high production standards.

Interview Tips

Preparing for an interview for an Electronic Die Maker position requires a well-rounded understanding of the role and its responsibilities. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, thoroughly research the company you are applying to and the specific Electronic Die Maker position. This will give you a deeper understanding of the company’s culture, values, and the specific requirements of the role.

- Review the company website, social media pages, and industry publications to gather information about their products, services, and market position.

- Study the job description carefully and identify the key skills, experience, and qualifications required for the position.

2. Highlight Your Skills and Experience

During the interview, emphasize your skills and experience that are relevant to the Electronic Die Maker position. Focus on your proficiency in die design, fabrication, maintenance, and quality control.

- Quantify your accomplishments whenever possible, using specific metrics and examples to demonstrate your impact.

- Be prepared to discuss your experience with different types of dies, materials, and manufacturing processes.

3. Showcase Your Problem-Solving Abilities

Electronic Die Makers often face complex problems in their work. In the interview, be prepared to share examples of how you have solved technical problems in the past.

- Describe a time when you encountered a challenging problem with a die and how you used your analytical skills and technical knowledge to resolve it.

- Emphasize your ability to think critically, identify root causes, and develop effective solutions.

4. Demonstrate Your Attention to Detail

Attention to detail is crucial for Electronic Die Makers. In the interview, provide examples of how you pay attention to precision and accuracy in your work.

- Share an instance where you detected a minor defect in a die component and took proactive steps to prevent it from affecting production.

- Discuss your approach to quality assurance and how you ensure that dies meet the required specifications.

5. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions that demonstrate your enthusiasm and curiosity about the role and the company.

- Inquire about the company’s current projects and future plans.

- Ask about the training and development opportunities available for Electronic Die Makers within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electronic Die Maker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!