Are you gearing up for a career in Electronic Gluing Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Electronic Gluing Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

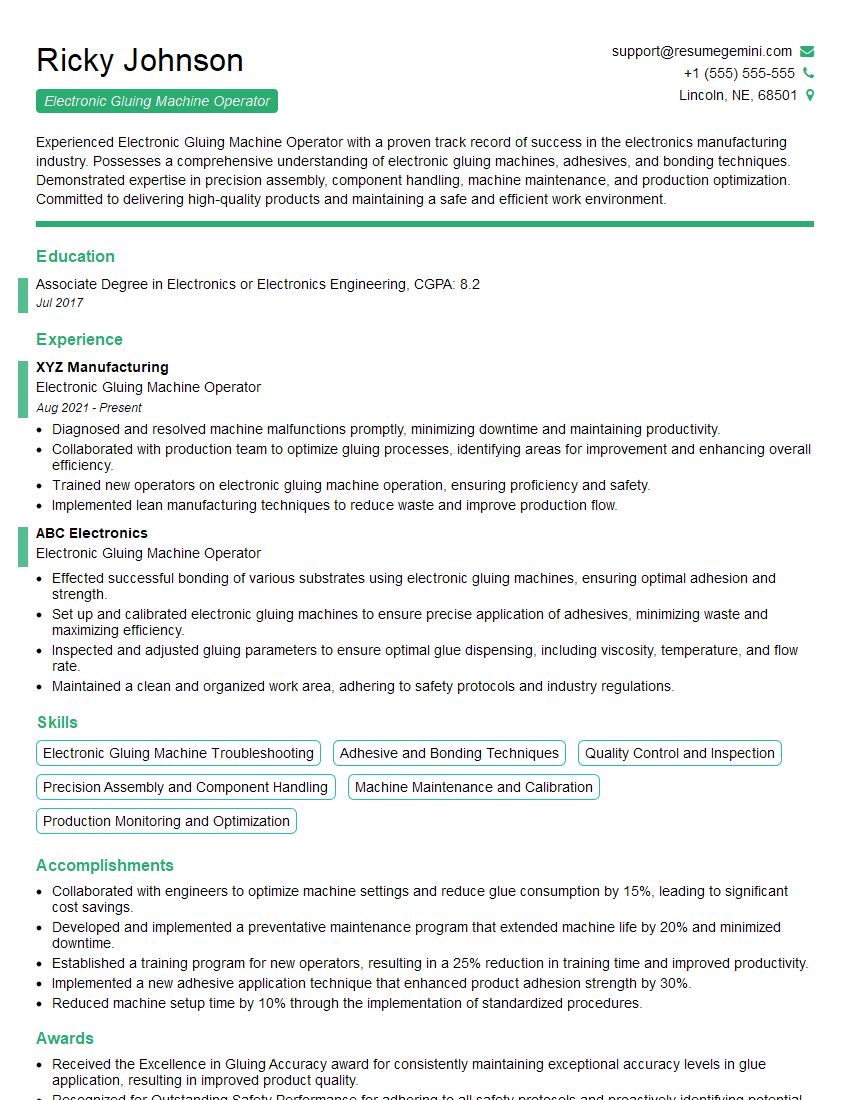

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electronic Gluing Machine Operator

1. Describe the process of loading and unloading the machine with substrate and electronic components.

- Securely load the substrate onto the machine’s table, ensuring proper alignment with the gluing patterns.

- Carefully place the electronic components onto the designated areas of the substrate, following the specified layout.

- Unload the finished product from the machine, ensuring that the glued components are secure and the substrate is intact.

2. Explain how to calibrate and maintain the machine for optimal gluing results.

Calibration

- Check and adjust the machine’s settings for proper dispensing accuracy, temperature, and pressure.

- Ensure the dispensing nozzle is aligned precisely and calibrated for the specific glue type and application.

Maintenance

- Clean the machine regularly to prevent glue buildup and nozzle clogging.

- Inspect and replace worn or damaged parts as needed to maintain optimal performance.

3. What are the key safety precautions to follow when operating an electronic gluing machine?

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a lab coat.

- Ensure the work area is well-ventilated to avoid exposure to glue fumes.

- Follow proper handling and storage procedures for the glue and substrates.

- Report any malfunctions or safety concerns promptly to the supervisor.

4. How do you ensure the quality of the glued products?

- Inspect the glued components for proper alignment, glue coverage, and secure bonding.

- Use specialized testing equipment to verify the strength and durability of the glued joints.

- Document and record inspection results for quality control purposes.

5. Describe the different types of glues used in electronic gluing machines and their applications.

- Epoxy adhesives: High strength, durable, and resistant to harsh environments.

- Acrylic adhesives: Fast-curing, clear, and provide good bonding strength.

- Cyanoacrylate adhesives: Quick-setting, ideal for small and precise bonding applications.

6. How do you troubleshoot common issues that may arise with the electronic gluing machine?

- No glue dispensing: Check nozzle clogging, glue supply, and dispensing settings.

- Poor adhesion: Verify component alignment, glue type suitability, and curing parameters.

- Glue leakage: Inspect nozzle for damage, adjust pressure settings, or use a different glue type.

7. What are the best practices for minimizing glue waste and maximizing efficiency in electronic gluing?

- Use the appropriate glue type and viscosity for the application.

- Optimize dispensing parameters to minimize glue overflow and waste.

- Implement proper glue dispensing techniques to avoid excessive consumption.

8. How do you stay updated with the latest advancements in electronic gluing technology?

- Attend industry conferences and workshops.

- Read technical publications and research articles.

- Engage with industry experts and manufacturers.

9. What is your experience with implementing process improvements for electronic gluing operations?

- Optimized machine settings to reduce glue consumption.

- Developed a quality control system to ensure product consistency.

- Improved process efficiency through automation and lean manufacturing principles.

10. How do you ensure that all glued products meet the required specifications and quality standards?

- Adhere to strict adherence to established manufacturing processes and quality control protocols.

- Utilize precision measurement and testing equipment to verify compliance.

- Maintain detailed records of product inspections and quality data.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electronic Gluing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electronic Gluing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Electronic Gluing Machine Operator is responsible for operating and maintaining electronic gluing machines used in the assembly of electronic components or devices. They ensure that the machines are operating efficiently and producing high-quality products.

1. Machine Operation

Sets up and operates electronic gluing machines according to specifications.

- Loads and unloads materials, including substrates, adhesives, and electronic components.

- Adjusts machine settings, such as temperature, pressure, and speed, to achieve optimal gluing results.

2. Quality Control

Inspects glued products for defects and ensures that they meet quality standards.

- Uses visual inspection techniques and measuring instruments to verify product dimensions, alignment, and bonding strength.

- Identifies and corrects any deviations from specifications, and reports any issues to supervisors.

3. Maintenance

Performs routine maintenance and troubleshooting on electronic gluing machines.

- Cleans and lubricates machine components.

- Replaces worn or damaged parts.

- Calibrates and adjusts machines to ensure accuracy and precision.

4. Safety

Adheres to all safety regulations and procedures in the workplace.

- Wears appropriate personal protective equipment (PPE), such as gloves, safety glasses, and lab coats.

- Follows proper handling and storage procedures for hazardous materials, such as adhesives and solvents.

Interview Tips

Preparing thoroughly for an interview is crucial for success. Here are some tips to help candidates ace their Electronic Gluing Machine Operator interview:

1. Research the Company and the Role

Before the interview, take the time to research the company and the specific role you are applying for. This will help you understand the company’s culture, products, services, and the key responsibilities of the position.

2. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful answers. Practice answering questions related to your experience, skills, knowledge of electronic gluing machines, quality control techniques, and troubleshooting abilities.

3. Highlight Relevant Experience and Skills

During the interview, emphasize your relevant experience and skills that align with the job requirements. Quantify your accomplishments whenever possible, using specific examples to demonstrate your proficiency.

4. Be Enthusiastic and Confident

Project a positive and enthusiastic attitude throughout the interview. Confidence in your abilities and a genuine interest in the role will make a lasting impression on the interviewers.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Electronic Gluing Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.