Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electronic Wirer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

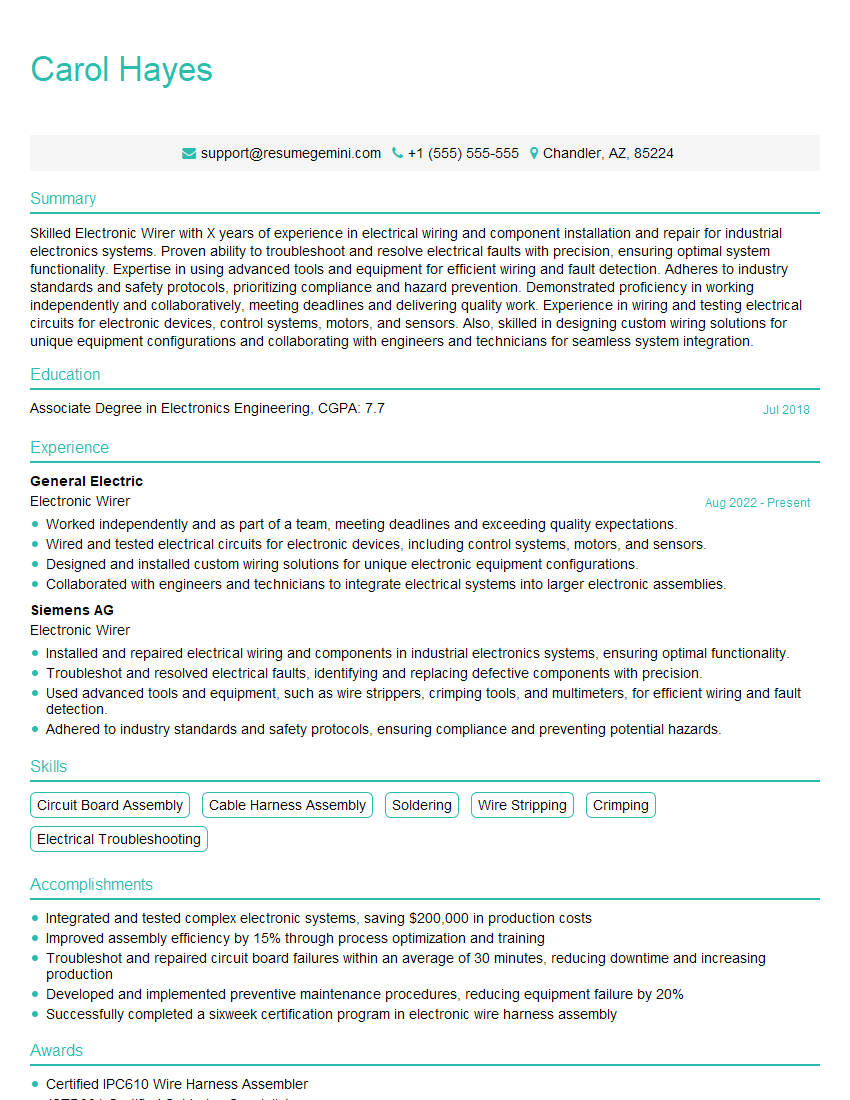

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electronic Wirer

1. What different types of electronic wiring do you have experience with?

In my previous roles, I have worked with various types of electronic wiring, including:

- PCB (printed circuit board) wiring

- Coaxial cable wiring

- Fiber optic cable wiring

- High-voltage wiring

- Low-voltage wiring

2. What are the different types of soldering techniques used in electronic wiring?

Flux-cored solder

- Pros: Easy to use, provides a good electrical connection

- Cons: Can be messy, can leave flux residue

Solid core solder

- Pros: Cleaner than flux-cored solder, provides a stronger electrical connection

- Cons: More difficult to use, requires separate flux

3. What is the difference between a stranded wire and a solid wire? When would you use each type?

- Stranded wire is made up of multiple thin strands of wire twisted together. It is more flexible than solid wire and is therefore better suited for applications where the wire will be subjected to movement or vibration.

- Solid wire is made up of a single strand of wire. It is more rigid than stranded wire and is therefore better suited for applications where the wire will not be subjected to movement or vibration.

4. What are the different types of wire gauges and what are their applications?

Wire gauge is a measure of the thickness of a wire. The thicker the wire, the lower the gauge number. Some common wire gauges and their applications include:

- 10 AWG: Used for high-current applications, such as power distribution

- 12 AWG: Used for medium-current applications, such as lighting circuits

- 14 AWG: Used for low-current applications, such as signal circuits

- 16 AWG: Used for very low-current applications, such as data transmission

5. What are the different types of wire insulation and what are their properties?

There are many different types of wire insulation, each with its own unique properties. Some common types of wire insulation include:

- PVC (polyvinyl chloride): PVC is a common type of wire insulation that is inexpensive and durable. It is resistant to moisture, heat, and chemicals.

- XLPE (cross-linked polyethylene): XLPE is a type of wire insulation that is more expensive than PVC, but it is also more flexible and durable. It is resistant to moisture, heat, and chemicals, and it can be used in high-voltage applications.

- Teflon (PTFE): Teflon is a type of wire insulation that is very expensive, but it is also the most durable. It is resistant to moisture, heat, chemicals, and radiation.

6. What are the different types of wire connectors and how are they used?

There are many different types of wire connectors, each with its own unique purpose. Some common types of wire connectors include:

- Butt connectors: Butt connectors are used to connect two wires together end-to-end.

- Splice connectors: Splice connectors are used to connect two or more wires together in a parallel configuration.

- Ring terminals: Ring terminals are used to connect a wire to a terminal block or other electrical device.

- Fork terminals: Fork terminals are used to connect a wire to a battery or other electrical device.

7. What are the safety precautions that should be taken when working with electrical wiring?

When working with electrical wiring, it is important to take the following safety precautions:

- Always wear appropriate safety gear, such as gloves, safety glasses, and a hard hat.

- Never work on live electrical circuits. Always turn off the power before starting work.

- Use proper tools and materials. Make sure that the tools and materials you are using are rated for the voltage and amperage of the circuit you are working on.

- Be aware of your surroundings. Make sure that there are no flammable materials or other hazards in the area where you are working.

- Follow all safety codes and regulations. Make sure that you are familiar with the safety codes and regulations that apply to the work you are doing.

8. What are the different types of test equipment used to troubleshoot electrical wiring?

There are many different types of test equipment that can be used to troubleshoot electrical wiring. Some common types of test equipment include:

- Multimeters: Multimeters can be used to measure voltage, current, and resistance.

- Clamp meters: Clamp meters can be used to measure current without breaking the circuit.

- Insulation testers: Insulation testers can be used to test the insulation resistance of electrical wiring.

- Circuit tracers: Circuit tracers can be used to trace the path of electrical circuits.

- Megohmmeters: Megohmmeters can be used to measure the resistance of insulation.

9. What are the different types of repairs that can be performed on electrical wiring?

The type of repair that can be performed on electrical wiring depends on the type of damage that has occurred. Some common types of repairs include:

- Splicing: Splicing is a method of repairing broken wires by connecting them together with a splice connector.

- Soldering: Soldering is a method of repairing broken wires by melting solder onto the ends of the wires and joining them together.

- Insulating: Insulating is a method of repairing damaged insulation by wrapping the damaged area with electrical tape or heat shrink tubing.

- Replacing: Replacing is a method of repairing damaged wiring by cutting out the damaged section and replacing it with new wiring.

10. What are the different types of electrical schematics and how are they used?

There are many different types of electrical schematics, each with its own unique purpose. Some common types of electrical schematics include:

- Block diagrams: Block diagrams show the overall layout of an electrical system, including the major components and their interconnections.

- Circuit diagrams: Circuit diagrams show the detailed electrical connections between the components of an electrical system.

- Wiring diagrams: Wiring diagrams show the physical layout of the wiring in an electrical system.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electronic Wirer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electronic Wirer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electronic Wirers are responsible for assembling, installing, and maintaining electrical systems and components. They work with a variety of materials, including wires, cables, and connectors, to create electrical circuits that power and control electronic devices. Some of the key job responsibilities of an Electronic Wirer include:

1. Assembling Electrical Systems

Electronic Wirers assemble electrical systems according to design specifications. They use a variety of tools and equipment to connect wires, cables, and connectors, and to test the functionality of the system.

- Read and interpret electrical diagrams and schematics

- Select and use appropriate tools and equipment

- Connect wires, cables, and connectors according to specifications

- Test the functionality of electrical systems

2. Installing Electrical Systems

Electronic Wirers install electrical systems in a variety of settings, including buildings, vehicles, and industrial machinery. They work with other tradespeople, such as electricians and plumbers, to ensure that electrical systems are installed safely and correctly.

- Install electrical systems according to code requirements

- Work with other tradespeople to ensure safe and correct installation

- Troubleshoot and repair electrical systems

3. Maintaining Electrical Systems

Electronic Wirers maintain electrical systems to ensure that they are operating safely and efficiently. They perform regular inspections and maintenance tasks, such as checking connections, testing components, and replacing worn or damaged parts.

- Perform regular inspections and maintenance tasks

- Troubleshoot and repair electrical systems

- Maintain records of electrical system maintenance

Interview Tips

Preparing for an interview for an Electronic Wirer position can be a daunting task, but following a few tips can help you ace the interview and land the job. Here are some tips to help you prepare:

1. Research the Company and the Position

Before you go on an interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, values, and goals, as well as the specific requirements of the position. You can research the company’s website, social media pages, and news articles to learn more about them.

2. Practice Answering Common Interview Questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice answering these questions in advance so that you can deliver your answers confidently and clearly.

3. Prepare Questions to Ask the Interviewer

Asking the interviewer questions at the end of the interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the company and the position. Some good questions to ask include “What are the biggest challenges facing the company right now?” and “What are the opportunities for advancement within the company?”

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally and arrive on time for your interview. This shows the interviewer that you are serious about the position and that you respect their time.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Electronic Wirer, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Electronic Wirer positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.