Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Electronics Inspector interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Electronics Inspector so you can tailor your answers to impress potential employers.

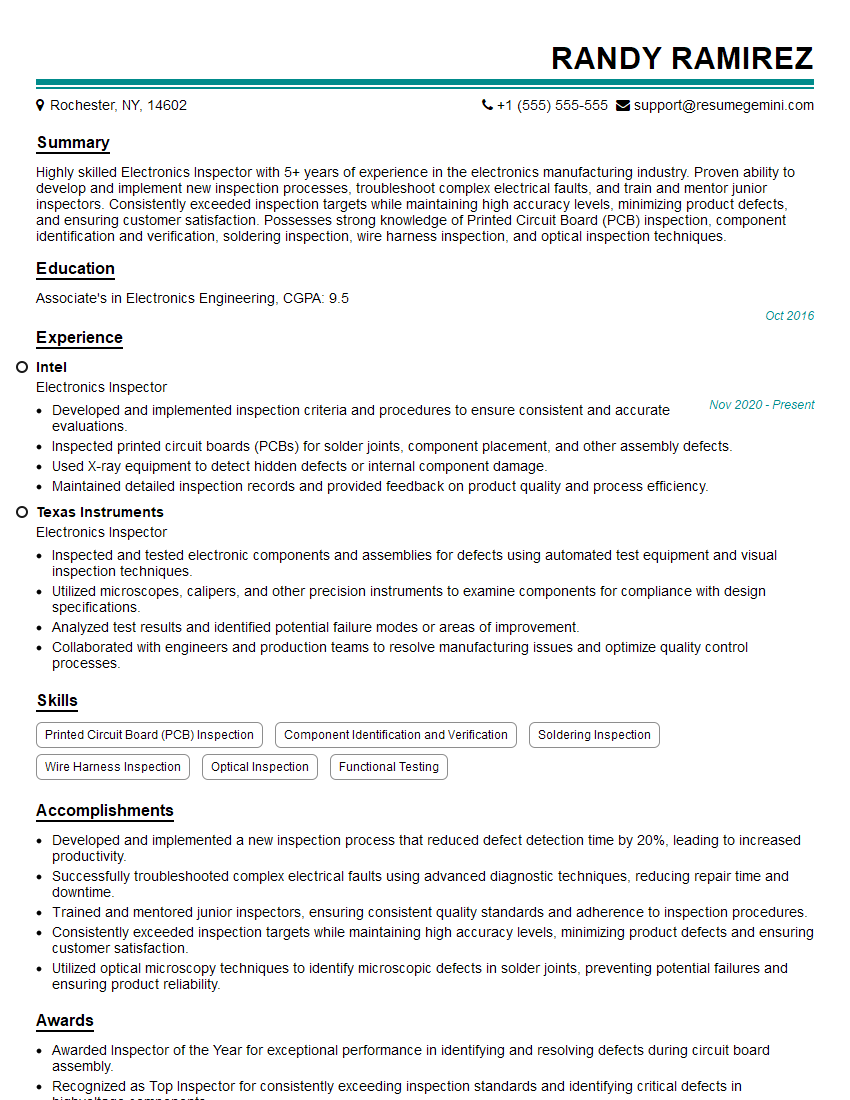

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electronics Inspector

1. What is the importance of ESD control in electronics inspection?

ESD control is crucial in electronics inspection to prevent damage to sensitive electronic components due to electrostatic discharge. It involves implementing measures like grounding equipment, using anti-static materials, and maintaining a clean and dry work environment to minimize the risk of ESD events.

2. Explain the role of visual inspection in electronics inspection.

Checking for Physical Defects

- Detect defects such as scratches, dents, or missing components on PCBs and other electronic assemblies.

- Identify any deviations from design specifications or manufacturing standards.

Assessing Assembly Quality

- Inspect soldering joints for proper formation, alignment, and solderability.

- Verify the correct placement and orientation of components, cables, and connectors.

Identifying Potential Issues

- Detect signs of overheating, burn marks, or discoloration on components.

- Identify any potential areas of concern or deviations that may require further investigation or testing.

3. Describe the different types of test equipment used in electronics inspection.

- Digital Multimeters: Measure voltage, current, and resistance to check electrical continuity and insulation.

- Logic Analyzers: Capture and analyze digital signals to verify logic functionality.

- Oscilloscopes: Display and analyze electrical signals to troubleshoot timing issues and signal quality.

- Automated Optical Inspection (AOI) Systems: Use cameras and image processing to perform high-volume visual inspections with precision and speed.

- X-ray Inspection Systems: Non-destructive testing method used to inspect hidden areas of assemblies for defects, such as solder joints and component placement.

4. How do you ensure the accuracy and consistency of your inspections?

- Adhering to Inspection Standards: Follow established inspection procedures and industry standards to maintain consistency.

- Using Calibrated Equipment: Regularly calibrate test equipment to ensure accurate readings and reliable results.

- Regular Training and Certification: Participate in training programs and obtain industry certifications to stay up-to-date on best practices and technologies.

- Cross-Verification and Double-Checking: Implement a system of cross-verification and double-checking to minimize errors and ensure accuracy.

5. What are the common challenges you encounter in electronics inspection?

- Identifying Defects in Complex Assemblies: Inspecting densely populated PCBs with numerous components can be challenging to identify defects visually.

- Troubleshooting Intermittent Issues: Diagnosing and resolving intermittent electrical issues requires patience and thorough troubleshooting techniques.

- Keeping Up with Technological Advancements: The electronics industry is constantly evolving, requiring inspectors to stay informed about new technologies and inspection methods.

- Ensuring Inspection Efficiency: Balancing thorough inspections with efficient processes to meet production deadlines can be a challenge.

6. How do you handle discrepancies between your inspection results and those of other inspectors?

- Communicate and Discuss: Discuss the discrepancies with the other inspector to understand their findings and perspective.

- Re-Inspect the Unit: Re-inspect the unit independently to verify your own observations and identify any potential errors.

- Consult with a Supervisor or Engineer: Seek guidance and support from a supervisor or engineer if necessary to resolve the discrepancies.

- Document and Record: Document the discrepancies, discussions, and resolution to prevent future misunderstandings.

7. Describe your experience with rework and repair of electronic assemblies.

- Identify and Repair Defects: Identify and repair defects such as faulty soldering joints, damaged components, or incorrect assembly.

- Follow Repair Procedures: Adhere to established repair procedures and use appropriate tools and materials.

- Test and Verify Repairs: Conduct thorough testing to ensure that repairs are successful and the assembly meets specifications.

- Document Repair History: Maintain accurate records of all repairs performed, including the nature of the defect, repair actions taken, and test results.

8. How do you stay up-to-date with advancements in electronics inspection technology?

- Attend Industry Events and Conferences: Participate in industry events and conferences to learn about new technologies and best practices.

- Read Technical Publications and Journals: Review technical publications, journals, and online resources to stay informed about industry trends.

- Undergo Training and Certification: Enroll in training programs and obtain industry certifications to enhance knowledge and skills.

- Network with Industry Professionals: Connect with other electronics inspectors and experts to share knowledge and experiences.

9. What are the qualities of a successful Electronics Inspector?

- Attention to Detail: Ability to identify and detect even minor defects or discrepancies.

- Strong Analytical Skills: Ability to troubleshoot and resolve electrical and mechanical issues.

- Technical Knowledge: Understanding of electronics principles, circuits, and components.

- Manual Dexterity: Ability to handle delicate components and perform repairs with precision.

- Excellent Communication Skills: Ability to convey inspection findings, discuss discrepancies, and provide clear documentation.

10. How do you prioritize inspection tasks and manage your time effectively?

- Establish Inspection Priorities: Determine the criticality and urgency of inspection tasks based on factors such as product specifications, deadlines, and customer requirements.

- Create a Structured Schedule: Plan and allocate time for each inspection task, considering the complexity and estimated duration.

- Use Inspection Tools and Technology: Leverage automated inspection systems and other tools to improve efficiency and reduce inspection time.

- Delegate and Collaborate: If necessary, delegate certain inspection tasks to team members or collaborate with other inspectors to optimize time management.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electronics Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electronics Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

In a fast-paced manufacturing environment, the Electronics Inspector plays a pivotal role in ensuring product quality and reliability. Their responsibilities entail:

1. Visual and Functional Inspection

The inspector meticulously examines electronic components, assemblies, and finished products against specifications, using visual aids and specialized testing equipment.

- Inspecting for defects, deviations, and compliance with design specifications

- Testing functionality and operability of electronic systems and devices

2. Quality Control and Assurance

They actively participate in establishing and maintaining quality standards, ensuring consistent production of high-quality electronics.

- Adhering to established quality control procedures and industry standards

- Identifying and rectifying quality issues promptly

- Providing feedback and suggestions for process improvement

3. Documentation and Reporting

The inspector maintains accurate records of inspection findings, test results, and product disposition.

- Completing inspection reports and documentation

- Communicating inspection results to relevant stakeholders

4. Troubleshooting and Analysis

When defects or issues arise, the inspector investigates and diagnoses the root cause to prevent recurrence.

- Analyzing test data and defect patterns

- Troubleshooting and resolving complex technical issues

- Suggesting corrective actions to improve product quality

Interview Tips

To ace the interview for an Electronics Inspector position, consider these strategies:

1. Research the Company and Role

Demonstrate your interest in the company and the position by researching their website, products, and industry reputation. Familiarize yourself with the key responsibilities and expectations to align your answers accordingly.

2. Highlight Relevant Skills and Experience

Emphasize your technical proficiency in electronics inspection, including your expertise in visual inspection, testing methodologies, and quality control procedures. Share specific examples of complex issues you have resolved and improvements you have implemented.

3. Showcase Your Attention to Detail

Stress your meticulous nature and ability to detect even the slightest defects or deviations. Explain how you use your keen observation and analytical skills to ensure product accuracy and reliability.

4. Prepare for Technical Questions

Anticipate technical questions related to electronics principles, test equipment, and troubleshooting techniques. Brush up on your knowledge of electrical components, circuit analysis, and quality standards to present yourself as a knowledgeable professional.

5. Convey Enthusiasm and Problem-Solving Skills

Express your passion for electronics and your eagerness to contribute to the company’s quality assurance efforts. Describe your problem-solving approach and how you apply it to identify and resolve technical issues effectively.

6. Prepare Example Outline

Consider preparing an outline of key points you want to convey during the interview. Organize your answers to common questions using the STAR method (Situation, Task, Action, Result). This will help you deliver structured and impactful responses.

Example Outline:

- Tell us about a time when you identified a critical defect that could have impacted product safety.

- Describe a project where you implemented a process improvement that significantly reduced product failures.

- Explain how you approach troubleshooting complex technical issues in electronic devices.

- Share an example of how your attention to detail led to the discovery of a potential hazard.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electronics Inspector interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.