Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electroplating Laborer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

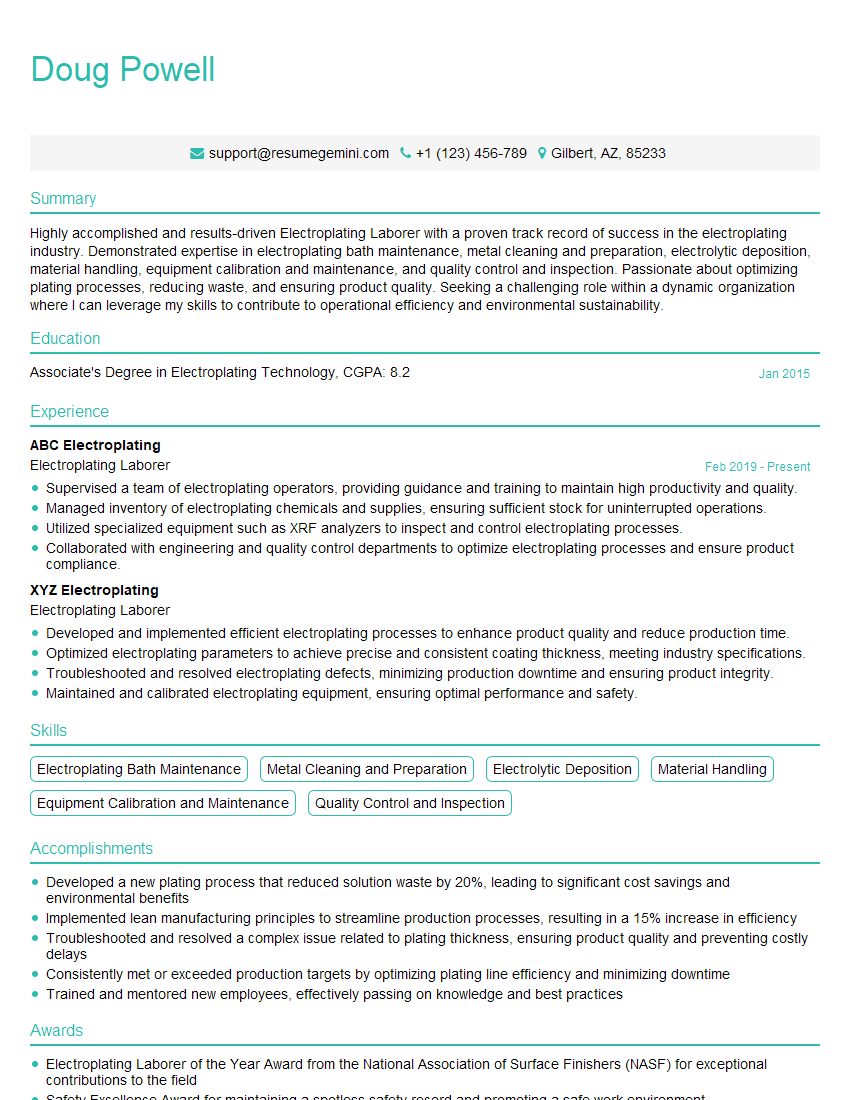

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electroplating Laborer

1. What are the different types of electroplating processes?

- Electroplating: This is the most common type of electroplating. A metal coating is deposited onto the surface of a conductive object (substrate) by electrochemical reactions.

- Electroless plating: This type of electroplating does not require an external power source. The deposition of metal coating is done by a chemical reducing agent, usually in an aqueous solution.

2. What are the steps involved in the electroplating process?

Surface Preparation

- Cleaning

- Rinsing

- Pickling

Electroplating

- Striking

- Plating

Post Treatment

- Rinsing

- Drying

- Inspection

3. What are the different types of plating solutions used in electroplating?

- Acidic plating solutions: These solutions contain a high concentration of acid (such as sulfuric acid or hydrochloric acid) and are used for plating metals such as copper, nickel, and zinc.

- Alkaline plating solutions: These solutions contain a high concentration of alkali (such as sodium hydroxide or potassium hydroxide) and are used for plating metals such as gold, silver, and tin.

- Neutral plating solutions: These solutions have a pH close to 7 and are used for plating metals such as lead, tin, and zinc.

4. What are the factors that affect the quality of the electroplated deposit?

- Surface preparation

- Plating solution composition

- Electroplating current and voltage

- Plating time and temperature

5. What are the different methods used to control the thickness of the electroplated deposit?

- Controlling the plating current and voltage

- Using a plating thickness gauge

- Using a microsection

6. What are the different types of equipment used in electroplating?

- Electroplating tanks

- Electroplating power supplies

- Electroplating filters

- Electroplating racks

7. What are the safety precautions that should be taken when working with electroplating chemicals?

- Wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and a lab coat.

- Work in a well-ventilated area.

- Handle chemicals carefully and avoid contact with skin and eyes.

- Dispose of chemicals properly.

8. What are the environmental regulations that apply to electroplating operations?

- Clean Air Act

- Clean Water Act

- Resource Conservation and Recovery Act

9. What is the role of an electroplating laborer?

- Prepare and clean surfaces for electroplating

- Operate electroplating equipment

- Monitor and control electroplating process

- Maintain electroplating equipment and work area

10. What skills and qualifications are required to be an electroplating laborer?

- High school diploma or equivalent

- Experience in electroplating or a related field

- Knowledge of electroplating processes and equipment

- Ability to read and understand blueprints

- Ability to work independently and follow instructions

- Strong safety awareness

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electroplating Laborer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electroplating Laborer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electroplating Laborers are responsible for operating and maintaining electroplating equipment, preparing and cleaning parts for plating, and performing other tasks related to the electroplating process.

1. Operating and Maintaining Equipment

Electroplating Laborers must be able to operate and maintain a variety of electroplating equipment, including plating tanks, rectifiers, and filtration systems.

- Monitor and adjust plating parameters, such as temperature, pH, and current density.

- Perform routine maintenance on equipment, such as cleaning tanks and filters.

2. Preparing and Cleaning Parts

Electroplating Laborers are responsible for preparing and cleaning parts prior to plating.

- Remove dirt, oil, and other contaminants from parts using a variety of methods, such as degreasing, pickling, and etching.

- Mask off areas of parts that should not be plated.

3. Performing Quality Control Procedures

Electroplating Laborers are responsible for performing quality control procedures to ensure that plated parts meet specifications.

- Inspect plated parts for defects, such as pits, scratches, and blisters.

- Perform thickness testing to ensure that plated parts meet the required specifications.

4. Maintaining a Clean and Safe Work Environment

Electroplating Laborers are responsible for maintaining a clean and safe work environment.

- Clean up spills and leaks.

- Follow all safety procedures, such as wearing proper personal protective equipment.

Interview Tips

To help you ace your interview for an Electroplating Laborer position, here are some tips and tricks

1. Research the Company and the Position

Before you go on your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

- Visit the company’s website to learn about their history, products, and services.

- Read online reviews of the company to get an idea of what it is like to work there.

- Talk to people in your network who may have worked for the company or know someone who does.

2. Prepare Answers to Common Interview Questions

There are some common interview questions that you can expect to be asked in an interview for an Electroplating Laborer position. Here are some examples of common questions and tips on how to answer them:

- Tell me about yourself. This is a common question that is used to get to know you and your background. In your answer, focus on your relevant experience and skills, and how they make you a good fit for the job.

- Why are you interested in this position? This question is used to assess your motivation for applying for the job. In your answer, explain why you are interested in the company and the position, and how your skills and experience make you a good fit.

- What are your strengths and weaknesses? This question is used to assess your self-awareness and your ability to identify your own strengths and weaknesses. In your answer, be honest about your strengths and weaknesses, and focus on how your strengths can benefit the company.

3. Be Prepared to Talk About Your Experience

In your interview, you will likely be asked to talk about your relevant experience. Be prepared to discuss your experience in detail, and be able to provide specific examples of your accomplishments.

- If you have previous experience as an Electroplating Laborer, be sure to highlight your accomplishments in that role.

- If you do not have direct experience as an Electroplating Laborer, you can still highlight your relevant skills and experience. For example, if you have experience in a related field, such as manufacturing or quality control, be sure to mention that in your interview.

4. Ask Questions

At the end of your interview, be sure to ask the interviewer some questions. This shows that you are interested in the position and the company. Some good questions to ask include:

- What are the company’s goals for this position?

- What is the company culture like?

- What are the opportunities for advancement?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electroplating Laborer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!