Feeling lost in a sea of interview questions? Landed that dream interview for Electroslag Welding Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Electroslag Welding Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

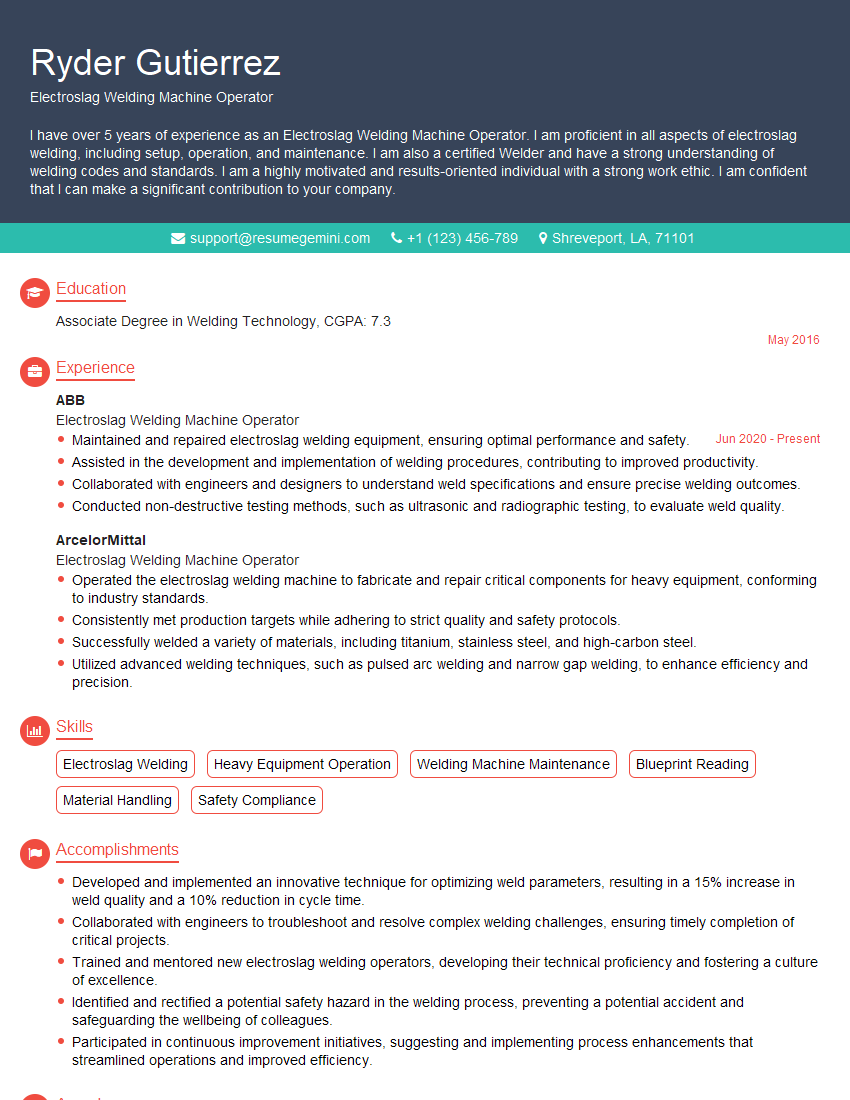

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electroslag Welding Machine Operator

1. Describe the basic steps involved in electroslag welding process?

- Prepare the joint by cleaning and chamfering the edges.

- Assemble the joint and secure it with clamps or fixtures.

- Set up the welding machine and select the appropriate welding parameters.

- Initiate the welding process by starting the molten slag bath.

- Feed the electrode wire into the molten slag bath and maintain a constant arc length.

- Control the welding process by monitoring the current, voltage, and other parameters.

- Complete the weld by filling the joint with molten metal and solidifying the slag.

- Remove the slag and clean the weld joint.

2. What are the advantages and disadvantages of electroslag welding?

Advantages:

- High deposition rates, resulting in increased productivity.

- Deep penetration, allowing for welding of thick sections in a single pass.

- Minimal distortion, making it suitable for welding large and complex structures.

- Good weld quality, with low levels of porosity and inclusions.

Disadvantages:

- Limited accessibility, as the process requires a closed joint.

- High equipment cost and setup time.

- Potential for slag entrapment if the process parameters are not controlled properly.

3. How do you ensure the quality of electroslag welds?

- Proper joint preparation and assembly.

- Selection and control of welding parameters (current, voltage, wire feed rate).

- Monitoring of the welding process, including slag bath temperature and electrode arc length.

- Control of slag chemistry and flux composition.

- Post-weld inspection and testing, such as visual inspection, radiography, and ultrasonic testing.

4. What are the safety considerations when operating an electroslag welding machine?

- Wear appropriate personal protective equipment (PPE), including welding helmet, gloves, and clothing.

- Ensure adequate ventilation to remove welding fumes.

- Handle molten slag and weld metal with care to avoid burns.

- Be aware of electrical hazards and follow safe electrical practices.

- Follow established work procedures and company safety regulations.

5. Describe the role of flux in electroslag welding?

- Creates and maintains the molten slag bath.

- Protects the weld pool from oxidation and contamination.

- Influences the weld metal composition and properties.

- Helps to remove impurities from the weld metal.

6. What are the different types of electrodes used in electroslag welding?

- Solid wire electrodes

- Flux-cored wire electrodes

- Composite electrodes

- Strip electrodes

7. How do you troubleshoot common problems in electroslag welding?

- Slag entrapment: Adjust welding parameters, flux composition, or joint design.

- Porosity: Check gas shielding, welding parameters, or joint preparation.

- Incomplete penetration: Increase welding current or wire feed rate, or reduce welding speed.

- Arc instability: Check electrical connections, wire feed system, or welding parameters.

8. What are the applications of electroslag welding?

- Fabrication of thick-section structures in shipbuilding, offshore platforms, and heavy machinery.

- Welding of large components in power generation, petrochemical, and mining industries.

- Repair and refurbishment of large structures, such as bridges, cranes, and pipelines.

9. Describe the differences between electroslag welding and submerged arc welding?

- Joint configuration: Electroslag welding requires a closed joint, while submerged arc welding can be used for both open and closed joints.

- Electrode type: Electroslag welding uses consumable electrodes, while submerged arc welding uses non-consumable electrodes.

- Flux usage: Electroslag welding utilizes a molten slag bath, while submerged arc welding uses a granular flux.

- Welding direction: Electroslag welding is mostly performed in the vertical down position, while submerged arc welding can be used in various positions.

10. What are the future trends in electroslag welding technology?

- Development of advanced fluxes and electrodes for improved weld quality and performance.

- Automation and process monitoring systems to enhance productivity and consistency.

- Exploration of new applications, such as welding of dissimilar materials and advanced materials.

- Research on reducing environmental impact and improving energy efficiency during electroslag welding.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electroslag Welding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electroslag Welding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electroslag Welding Machine Operators play a crucial role in the fabrication and construction industries, specializing in the operation of electroslag welding machines. Their primary responsibilities include:

1. Machine Operation and Maintenance

Operate and maintain electroslag welding machines, ensuring optimal performance and efficiency.

2. Welding Process Execution

Execute electroslag welding procedures according to specifications, following established safety guidelines.

3. Quality Control and Inspection

Monitor the welding process, inspect welds for defects, and ensure adherence to quality standards.

4. Setup and Preparation

Prepare and set up welding equipment, including electrodes, flux, and consumables.

5. Troubleshooting and Repair

Troubleshoot and repair welding equipment as needed, ensuring timely and efficient operations.

6. Coordination and Collaboration

Collaborate with other team members, such as engineers and quality control inspectors, to ensure project completion.

Interview Preparation Tips

To ace an interview for the Electroslag Welding Machine Operator position, it is crucial to be well-prepared. Here are some effective tips and hacks:

1. Research the Company and Industry

Familiarize yourself with the company’s history, values, and products. Research industry trends and advancements to demonstrate your knowledge.

2. Practice Your Welding Skills

Ensure your welding skills are up-to-date by practicing on sample materials or reviewing previous work.

3. Highlight Your Experience and Certifications

Emphasize your relevant experience in operating electroslag welding machines. Showcase any certifications or training that enhance your credibility.

4. Demonstrate Safety Awareness

Stress your adherence to safety protocols and regulations. Explain how you prioritize safety in your workplace.

5. Use Specific Examples

Provide concrete examples from your experience that demonstrate your skills and abilities. Quantify your accomplishments whenever possible.

6. Prepare Questions

Asking thoughtful questions at the end of the interview shows your engagement and interest in the role and company.

7. Professional Appearance and Attitude

Present yourself professionally and maintain a positive attitude throughout the interview. Dress appropriately and arrive on time.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electroslag Welding Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!