Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Electrotype Caster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

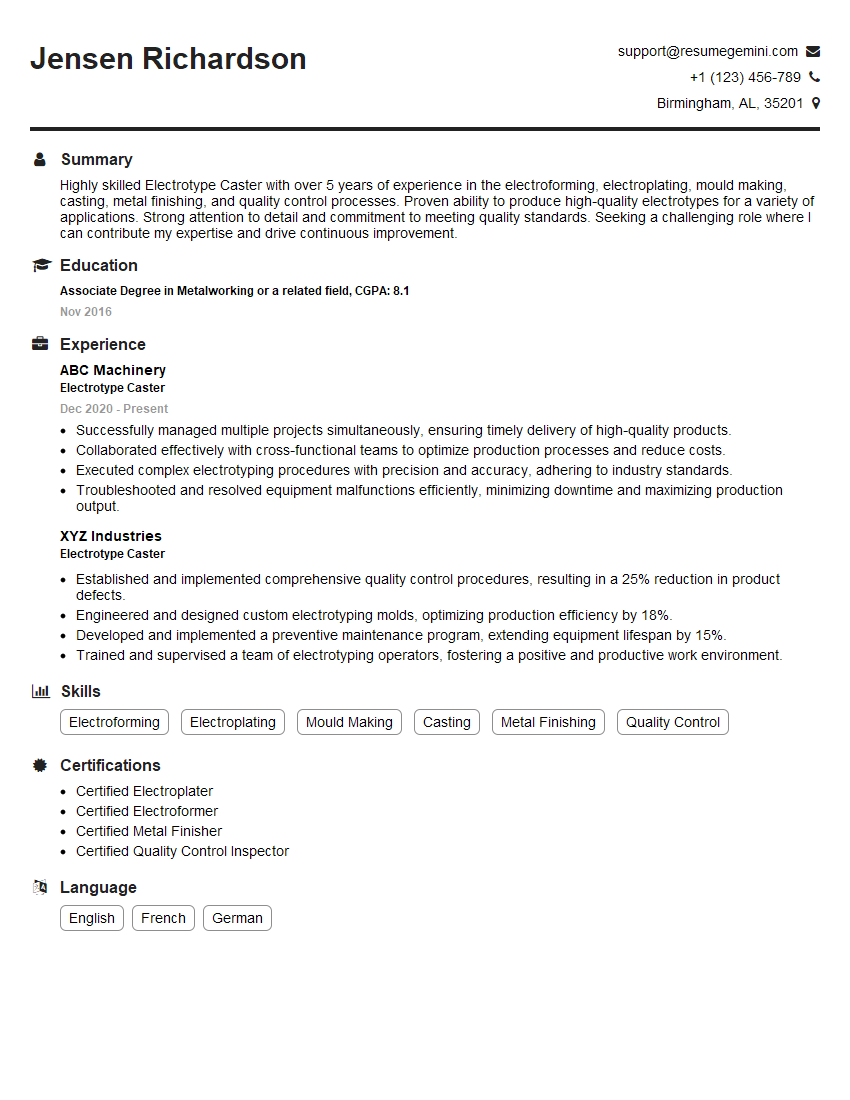

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrotype Caster

1. Describe the process of electrotyping?

Electrotyping is a process of creating a metal duplicate of an object using an electrolytic bath. It involves the following steps:

- Preparing the mold: The object to be duplicated is used to create a mold, typically made of wax or plastic.

- Creating the cathode: A conductive material, such as graphite or stainless steel, is used to create the cathode, which will serve as the base for the electroplated metal.

- Preparing the electrolytic bath: An electrolytic bath is prepared, consisting of a metal salt solution (e.g., copper sulfate) and an electrolyte (e.g., sulfuric acid).

- Electrolysis: The cathode and mold are placed in the electrolytic bath, and an electric current is passed through the solution. Metal ions from the solution are deposited onto the cathode, forming a metallic replica of the mold.

- Separating the electrotype: Once the electroplating process is complete, the electrotype is separated from the mold and polished to remove any imperfections.

2. What are the different types of electroplating solutions used in electrotyping?

- Acid copper: Widely used for electrotyping due to its high deposition rate and good surface finish. It produces a bright, smooth deposit.

- Cyanide copper: Produces a more ductile and malleable deposit, but is more toxic and requires careful handling.

- Nickel: Used for applications requiring high corrosion resistance and wear resistance. Produces a hard, durable deposit.

- Gold: Used for decorative purposes or for electrical applications. Produces a lustrous, corrosion-resistant deposit.

3. How do you determine the thickness of the electroplated metal?

The thickness of the electroplated metal can be determined using various methods:

- Micrometer: A micrometer can be used to measure the thickness of the electroplated layer by measuring the difference in thickness between the base metal and the electroplated surface.

- Cross-sectioning: A cross-section of the electroplated object can be examined under a microscope to measure the thickness of the metal deposit.

- Magnetic thickness gauge: A magnetic thickness gauge can be used to measure the thickness of non-magnetic electroplated coatings on magnetic base metals.

4. What factors affect the quality of the electroplated metal?

- Bath composition: The composition of the electrolytic bath, including the concentration of metal ions, pH, and temperature, can influence the quality of the electroplated metal.

- Current density: The current density applied during electrolysis affects the rate of deposition and the grain size of the metal deposit.

- Agitation: Agitation of the electrolytic bath helps to ensure uniform deposition and prevent the formation of defects.

- Substrate preparation: Proper preparation of the substrate before electroplating, including cleaning and activation, is essential for good adhesion and quality of the electroplated metal.

5. What are the safety precautions that must be taken when working with electroplating solutions?

Working with electroplating solutions requires careful adherence to safety precautions:

- Personal protective equipment: Wear appropriate personal protective equipment, including gloves, eye protection, and a lab coat, to minimize exposure to chemicals and electrical hazards.

- Ventilation: Ensure adequate ventilation in the work area to prevent the accumulation of toxic fumes.

- Electrical safety: Follow electrical safety protocols to prevent electrical shock and ensure proper grounding of equipment.

- Chemical handling: Handle electroplating solutions and chemicals with care, following proper disposal and storage procedures.

6. How do you troubleshoot common problems that may occur during electrotyping?

Common problems that may occur during electrotyping and their troubleshooting steps include:

- Poor adhesion: Check for proper substrate preparation, ensure the mold is clean and free of contaminants, and adjust the bath composition.

- Uneven deposition: Adjust the current density, agitation, and bath temperature to achieve uniform deposition.

- Burn marks: Reduce the current density and increase the agitation to prevent localized overheating and burning of the deposit.

- Treeing: Adjust the bath composition, current density, and agitation to minimize the formation of dendritic growth on the electroplated surface.

7. What are the applications of electrotyping?

- Duplication of objects: Electrotyping is used to create high-quality duplicates of objects for various purposes, such as art, historical preservation, and industrial applications.

- Electroforming: Electrotyping is employed to create hollow metal objects through a process known as electroforming, used in jewelry, electronics, and medical devices.

- Surface modification: Electroplating can be used to modify the surface properties of metal objects, enhancing their corrosion resistance, wear resistance, and electrical conductivity.

8. How do you stay updated on the latest advancements in electrotyping technology?

To stay updated on the latest advancements in electrotyping technology:

- Attend industry conferences and workshops: Participate in events where experts share their knowledge and research findings.

- Read technical journals and publications: Review industry-specific journals and publications to stay informed about new developments.

- Network with professionals: Connect with other electrotypers, researchers, and suppliers to exchange ideas and learn about emerging technologies.

9. What are the challenges and opportunities in the electrotyping industry?

Challenges

- Environmental regulations: Strict environmental regulations can impact the use and disposal of electroplating solutions and chemicals.

- Competition: The electrotyping industry faces competition from alternative manufacturing processes, such as 3D printing and CNC machining.

Opportunities

- Advanced materials: New advancements in materials science provide opportunities for developing electroplated coatings with enhanced properties.

- Growing demand: The increasing demand for high-quality metal products and surface treatments creates opportunities for electrotypers.

10. How do you plan to contribute to our company as an Electrotype Caster?

As an Electrotype Caster, I plan to contribute to your company in the following ways:

- Expertise and knowledge: Utilize my expertise in electrotyping to produce high-quality electroplated products that meet customer specifications.

- Problem-solving: Apply my problem-solving skills to address any challenges that may arise during the electrotyping process, ensuring efficient production and customer satisfaction.

- Collaboration: Collaborate effectively with other team members to optimize production processes and maintain a positive work environment.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrotype Caster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrotype Caster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrotype Casters are responsible for producing metal duplicates of molds using electroforming techniques. Their primary duties involve:

1. Mold Preparation

Preparing molds for electroforming by cleaning, inspecting, and applying conductive coatings.

- Cleaning molds to remove any dirt, debris, or contaminants.

- Inspecting molds for defects, such as cracks or voids, that could affect the electroforming process.

- Applying conductive coatings to the molds to facilitate the deposition of metal during electroforming.

2. Electroforming

Operating electroforming equipment to deposit metal onto the molds, creating duplicates.

- Setting up and operating electroforming baths, including preparing electrolytes and controlling temperature and current.

- Monitoring the electroforming process to ensure proper deposition of metal and prevent defects.

- Removing electroformed duplicates from the molds once the process is complete.

3. Post-Processing

Performing post-processing steps on electroformed duplicates, such as finishing and inspection.

- Cleaning and polishing electroformed duplicates to remove any excess metal or imperfections.

- Inspecting electroformed duplicates to ensure they meet the required specifications and standards.

- Packaging and storing electroformed duplicates for shipment or further processing.

4. Equipment Maintenance

Maintaining and troubleshooting electroforming equipment to ensure optimal performance.

- Performing regular inspections and maintenance on electroforming equipment, including cleaning and calibration.

- Troubleshooting and resolving any issues that arise with electroforming equipment to minimize downtime.

- Collaborating with maintenance technicians or engineers to address complex equipment issues.

Interview Tips

To ace an interview for an Electrotype Caster position, candidates should prepare thoroughly and demonstrate their knowledge and skills. Here are some interview tips:

1. Research the Role and Company

Research the specific responsibilities of an Electrotype Caster and the company’s electroforming processes. This will help you understand the requirements of the job and tailor your answers accordingly.

- Review the job description carefully and identify key skills and experience the employer is looking for.

- Visit the company’s website and social media pages to learn about their business and electroforming operations.

2. Highlight Relevant Skills and Experience

Emphasize your relevant skills and experience in mold preparation, electroforming, post-processing, and equipment maintenance. Use specific examples to demonstrate your abilities.

- Describe your involvement in electroforming projects, including the types of molds you worked with and the results you achieved.

- Provide examples of your attention to detail and quality control procedures when performing post-processing steps.

3. Practice Answering Common Interview Questions

Prepare for common interview questions about your technical skills, experience, and problem-solving abilities. Practice answering these questions concisely and effectively.

- Prepare answers to questions about your understanding of electroforming principles and processes.

- Be ready to discuss your troubleshooting techniques and how you handle unexpected challenges.

4. Ask Insightful Questions

Asking thoughtful questions during the interview demonstrates your interest in the role and the company. It also gives you an opportunity to clarify any aspects of the job or the electroforming process that you are unfamiliar with.

- Inquire about the specific electroforming techniques used by the company and the industry standards they adhere to.

- Ask about opportunities for professional development and career growth within the organization.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electrotype Caster interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.