Feeling lost in a sea of interview questions? Landed that dream interview for Electrotype Molder but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Electrotype Molder interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

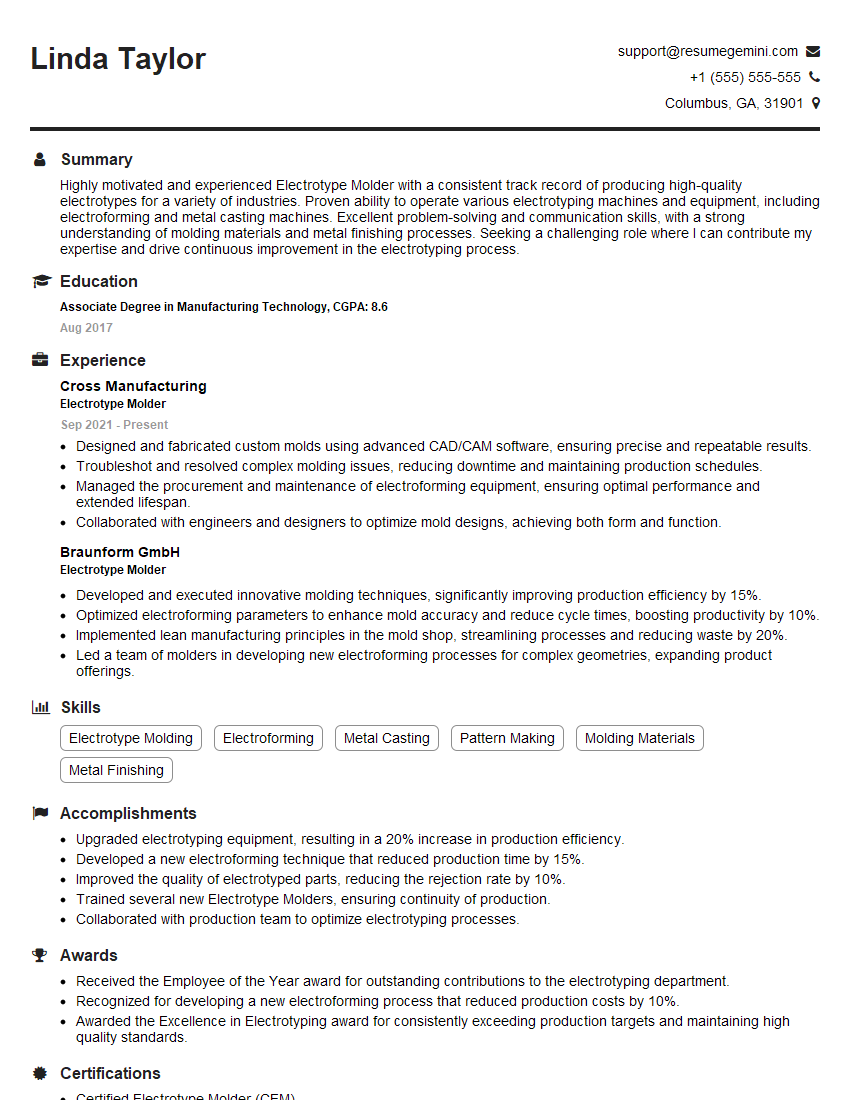

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Electrotype Molder

1. Describe the electrotyping process in detail.

- The electrotyping process involves creating a duplicate of an original object by electroplating it with a metal.

- First, a mold is made of the original object.

- The mold is then coated with a conductive material, such as graphite or silver.

- The mold is then placed in an electroplating bath, which contains a solution of the metal that will be used to create the duplicate.

- An electrical current is passed through the solution, which causes the metal to deposit on the mold.

- The metal will continue to deposit on the mold until the desired thickness is achieved.

- Once the desired thickness is achieved, the mold is removed from the bath and the duplicate object is complete.

2. What are the different types of molds that can be used in electrotyping?

- There are two main types of molds that can be used in electrotyping: rigid molds and flexible molds.

- Rigid molds are made of a hard material, such as metal or plastic.

- Flexible molds are made of a soft material, such as rubber or silicone.

- Rigid molds are more durable than flexible molds, but they can be more difficult to make.

- Flexible molds are easier to make than rigid molds, but they are not as durable.

3. What are the different types of metals that can be used in electrotyping?

- A variety of metals can be used in electrotyping, including copper, nickel, silver, and gold.

- Copper is the most common metal used in electrotyping because it is relatively inexpensive and easy to work with.

- Nickel is a good choice for electrotyping objects that will be exposed to wear and tear, such as jewelry or tools.

- Silver is a good choice for electrotyping objects that will be used for decorative purposes.

- Gold is a good choice for electrotyping objects that will be used for electronic applications.

4. What are the factors that affect the thickness of the electroplated metal?

- The thickness of the electroplated metal is determined by a number of factors, including the current density, the temperature of the solution, and the duration of the electroplating process.

- A higher current density will result in a thicker metal deposit.

- A higher temperature will also result in a thicker metal deposit.

- A longer duration of the electroplating process will also result in a thicker metal deposit.

5. What are the different applications of electrotyping?

- Electrotyping has a wide range of applications, including:

- The production of jewelry

- The production of tools

- The production of decorative objects

- The production of electronic components

- The repair of damaged objects

6. What are the safety precautions that must be taken when working with electrotyping?

- When working with electrotyping, it is important to take the following safety precautions:

- Wear gloves and eye protection.

- Use a well-ventilated area.

- Do not touch the electrical components of the electroplating system.

- Do not leave the electroplating system unattended.

- Dispose of chemicals properly.

7. What are the troubleshooting tips for electrotyping?

- Here are some troubleshooting tips for electrotyping:

- If the metal deposit is too thin, increase the current density, the temperature of the solution, or the duration of the electroplating process.

- If the metal deposit is too thick, decrease the current density, the temperature of the solution, or the duration of the electroplating process.

- If the metal deposit is not uniform, check the conductivity of the mold and the electrical connections.

- If the metal deposit is pitted or rough, increase the current density or the temperature of the solution.

8. What are the latest developments in electrotyping technology?

- Some of the latest developments in electrotyping technology include:

- The use of new materials, such as nanomaterials and composites, to create electroplated objects with unique properties.

- The development of new techniques to improve the efficiency and accuracy of the electroplating process.

- The use of electrotyping to create objects for new applications, such as in the medical and aerospace industries.

9. What is the future of electrotyping?

- Electrotyping is a versatile and powerful technology with a wide range of applications.

- As new materials and techniques are developed, the applications of electrotyping will continue to expand.

- Electrotyping is expected to play an increasingly important role in the manufacturing, repair, and decoration of objects in the future.

10. Do you have any questions for me?

- This is an opportunity for you to ask the interviewer any questions you may have about the position or the company.

- It is also a good opportunity to show the interviewer that you are interested in the position and the company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Electrotype Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Electrotype Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Electrotype Molders are responsible for creating electrotype molds for various industrial applications. Electrotype molds are used to produce high-quality metal parts. The key responsibilities of an Electrotype Molder include:

1. Mold Preparation

Preparing the mold surface by cleaning, polishing, and applying a release agent.

- Inspecting the mold surface for defects and repairing any imperfections.

- Applying a conductive coating to the mold surface.

2. Electroplating

Setting up and operating electroplating equipment.

- Monitoring the electroplating process to ensure the desired thickness and quality of the metal coating.

- Removing the metal coating from the mold after electroplating.

3. Mold Finishing

Inspecting the finished mold for defects and repairing any imperfections.

- Applying a protective coating to the mold.

- Storing the mold for future use.

4. Equipment Maintenance

Maintaining and calibrating electroplating equipment.

- Troubleshooting and repairing electroplating equipment.

- Ensuring that electroplating equipment is operating safely and efficiently.

Interview Tips

Preparing for an Electrotype Molder interview can help you showcase your skills and increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Role

Before the interview, take the time to research the company and the Electrotype Molder role. This will help you understand the company’s culture, values, and the specific requirements of the job.

- Visit the company’s website and social media pages.

- Read industry news and articles about electrotype molding.

- Look up electrotype molding equipment and techniques on Linkedin and other online forums.

2. Practice Your Answers

Take some time to practice answering common interview questions. This will help you feel more confident and prepared during the interview.

- Prepare a brief introduction of yourself and your experience.

- Practice describing your skills and abilities, focusing on those relevant to electrotype molding.

- Prepare examples of your work experience that demonstrate your skills and abilities.

3. Be Enthusiastic and Professional

During the interview, be enthusiastic and professional. Show the interviewer that you are interested in the role and that you have the skills and experience to be successful.

- Make eye contact with the interviewer.

- Speak clearly and confidently.

- Dress appropriately for the interview.

4. Ask Questions

At the end of the interview, ask the interviewer questions about the role and the company. This shows that you are interested in the position and that you are taking the interview seriously.

- Ask about the company’s culture and values.

- Ask about the specific responsibilities of the Electrotype Molder role.

- Ask about the company’s growth plans and opportunities for advancement.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Electrotype Molder interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.