Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Element Winding Machine Tender interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Element Winding Machine Tender so you can tailor your answers to impress potential employers.

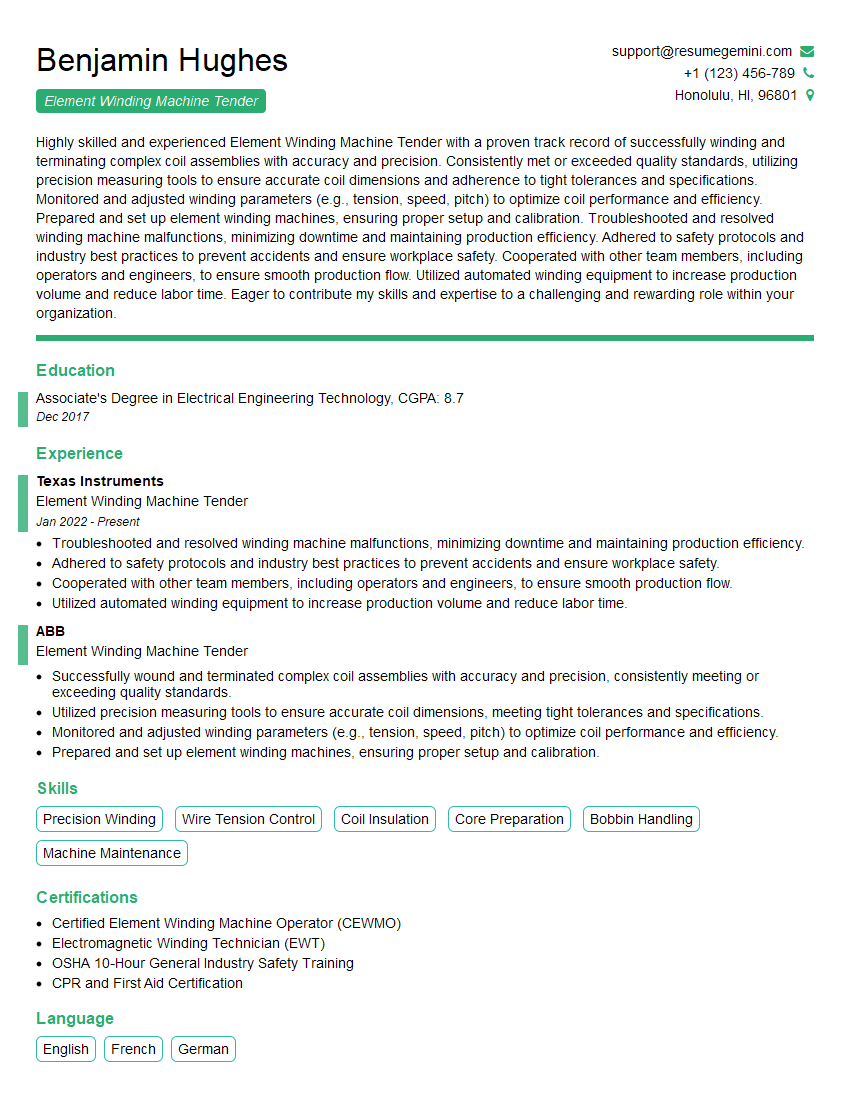

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Element Winding Machine Tender

1. Explain the process of winding elements in a transformer using an element winding machine?

The process involves several key steps:

- Preparation: Gather the necessary materials, including the conductor wire, insulation, and winding machine.

- Set up the machine: Configure the winding machine’s parameters, such as the wire tension, winding speed, and number of turns.

- Load the conductor wire: Secure the conductor wire onto the winding machine’s spool.

- Begin winding: Start the winding process, ensuring that the wire is wound evenly and tightly around the core.

- Insulate the windings: Apply insulation between layers of windings to prevent electrical shorts and ensure proper insulation.

- Complete the winding: Continue winding until the desired number of turns is achieved.

- Secure the windings: Tie or clamp the windings in place to prevent movement and ensure stability.

2. How do you determine the correct tension for winding the conductor wire?

Importance of Correct Tension

- Prevents wire breakage during winding.

- Ensures proper insulation and electrical performance.

Methods to Determine Tension

- Tension gauge: Use a tension gauge to measure the wire tension directly.

- Experience and judgment: Experienced winding machine operators can estimate the correct tension based on the wire size, winding speed, and machine settings.

- Manufacturer’s specifications: Refer to the manufacturer’s instructions or guidelines for recommended tension values.

3. Describe the different types of insulation used in element winding and their properties?

- Paper insulation: Made from cellulose fibers, providing good electrical insulation and moisture resistance.

- Nomex insulation: A synthetic material with high thermal stability and dielectric strength.

- Mylar insulation: A polyester film with excellent electrical properties and dimensional stability.

- Kapton insulation: A polyimide film with high-temperature resistance and chemical inertness.

4. How do you troubleshoot common issues that may occur during element winding?

- Wire breakage: Check wire tension, spool alignment, and machine settings.

- Uneven winding: Adjust machine parameters, inspect the conductor wire, and ensure proper tension.

- Electrical shorts: Verify insulation integrity, check for any exposed conductors, and inspect the winding pattern.

- Overheating: Check machine settings, ensure proper ventilation, and inspect for any binding or friction.

5. Explain the importance of quality control in element winding?

- Ensures product reliability: Proper winding techniques and quality control measures prevent defects that could lead to transformer failures.

- Optimizes transformer performance: Consistent winding quality ensures proper electrical characteristics, such as inductance and voltage withstand.

- Reduces maintenance costs: High-quality windings are less prone to insulation failures and other issues, minimizing maintenance requirements.

6. How do you maintain and calibrate an element winding machine?

- Regular cleaning and lubrication: Keep the machine clean and lubricated to prevent wear and tear.

- Tension calibration: Use a tension gauge to calibrate the machine’s tension settings regularly.

- Speed calibration: Check and adjust the winding speed to ensure it meets specifications.

- Mechanical inspection: Inspect the machine for any loose parts, worn components, or damage.

7. Describe the safety precautions that must be followed when operating an element winding machine?

- Wear appropriate PPE: Safety glasses, gloves, and ear protection.

- Secure loose clothing: Avoid loose clothing that could get caught in the machine.

- Keep work area clean and organized: Prevent tripping hazards and ensure easy access to controls.

- Follow lockout/tagout procedures: Lock out the machine before performing maintenance or repairs.

8. How do you interpret the technical drawings and specifications for an element winding project?

- Study the drawings thoroughly: Examine the dimensions, winding pattern, and insulation requirements.

- Identify key parameters: Note the wire size, number of turns, and type of insulation specified.

- Clarify any uncertainties: Consult with the engineering team or supervisor if any aspect of the drawings is unclear.

9. Explain how you ensure the accuracy and consistency of the winding process?

- Use calibrated equipment: Ensure that the winding machine and tension gauge are properly calibrated.

- Follow standard procedures: Adhere to established winding techniques and quality control guidelines.

- Inspect windings regularly: Monitor the winding process and inspect the windings for any defects or irregularities.

- Maintain records: Document winding parameters, inspection results, and any adjustments made to ensure traceability.

10. Describe your experience in working with different types of conductors and insulation materials?

- Conductors: Experience working with copper, aluminum, and other conductor materials, understanding their properties and handling requirements.

- Insulation: Knowledge of different insulation materials, their electrical characteristics, and application techniques.

- Adaptability: Ability to work with various materials and adjust winding techniques accordingly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Element Winding Machine Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Element Winding Machine Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Element Winding Machine Tender is responsible for the operation and maintenance of element winding machines. They work in a manufacturing environment and ensure that the machines are running smoothly and producing quality products.

1. Machine Operation

The primary responsibility of an Element Winding Machine Tender is to operate the element winding machine. This involves loading the machine with raw materials, setting up the machine for the desired product, and monitoring the machine during operation. They must also be able to troubleshoot any problems that may occur and make any necessary adjustments.

- Load the machine with raw materials, such as wire and insulation.

- Set up the machine for the desired product, including the winding pattern and tension.

- Monitor the machine during operation to ensure that it is running smoothly and producing quality products.

- Troubleshoot any problems that may occur, such as breaks in the wire or insulation.

- Make any necessary adjustments to the machine to ensure that it is operating properly.

2. Machine Maintenance

In addition to operating the machine, an Element Winding Machine Tender is also responsible for its maintenance. This involves regular cleaning and lubrication of the machine, as well as inspecting the machine for any signs of wear or damage. They must also be able to perform minor repairs on the machine and replace any worn or damaged parts.

- Clean and lubricate the machine on a regular basis.

- Inspect the machine for any signs of wear or damage.

- Perform minor repairs on the machine, such as replacing worn or damaged parts.

- Keep a log of all maintenance activities.

3. Quality Control

An Element Winding Machine Tender is also responsible for the quality of the products produced by the machine. They must be able to inspect the products for any defects and make any necessary adjustments to the machine to ensure that the products meet the required specifications.

- Inspect the products produced by the machine for any defects.

- Make any necessary adjustments to the machine to ensure that the products meet the required specifications.

- Keep a log of all quality control activities.

4. Safety

An Element Winding Machine Tender must also be aware of the safety hazards associated with operating the machine. They must be able to follow all safety procedures and wear the appropriate safety gear. They must also be able to identify any potential hazards and take steps to mitigate them.

- Follow all safety procedures.

- Wear the appropriate safety gear.

- Identify any potential hazards and take steps to mitigate them.

- Report any accidents or injuries to the supervisor.

Interview Tips

Preparing for an interview for the position of Element Winding Machine Tender requires careful consideration and planning. Here are some tips and hacks to help you ace the interview:

1. Research the Company

Before the interview, take the time to research the company. This will show the interviewer that you are interested in the position and that you have taken the time to learn about the company. You can research the company’s website, social media pages, and news articles.

- Visit the company’s website to learn about its history, mission, values, and products or services.

- Follow the company on social media to get a sense of its culture and recent news.

- Read news articles about the company to stay up-to-date on its latest developments.

2. Practice Your Answers

Once you have researched the company, take some time to practice your answers to common interview questions. This will help you to feel more confident and prepared during the interview. You can practice answering questions with a friend or family member, or you can record yourself answering questions.

- Think about common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

- Practice answering these questions out loud.

- Get feedback from a friend or family member on your answers.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for the interview. This means wearing clean, pressed clothes that are appropriate for a business setting. Avoid wearing casual or revealing clothing.

- Choose clothes that are clean, pressed, and fit well.

- Avoid wearing casual or revealing clothing.

- Consider wearing a suit or dress pants and a button-down shirt.

4. Be Punctual

Punctuality is important for any interview, but it is especially important for an interview for a manufacturing position. This shows the interviewer that you are reliable and that you respect their time. Arrive at the interview location on time, or even a few minutes early.

- Plan your route to the interview location in advance.

- Leave yourself plenty of time to get to the interview location.

- If you are running late, call the interviewer to let them know.

5. Be Yourself

The most important thing is to be yourself during the interview. The interviewer wants to get to know the real you, so don’t try to be someone you’re not. Be honest and genuine in your answers, and let your personality shine through.

- Be honest and genuine in your answers.

- Let your personality shine through.

- Don’t try to be someone you’re not.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Element Winding Machine Tender interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!