Are you gearing up for a career in Emblem Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Emblem Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

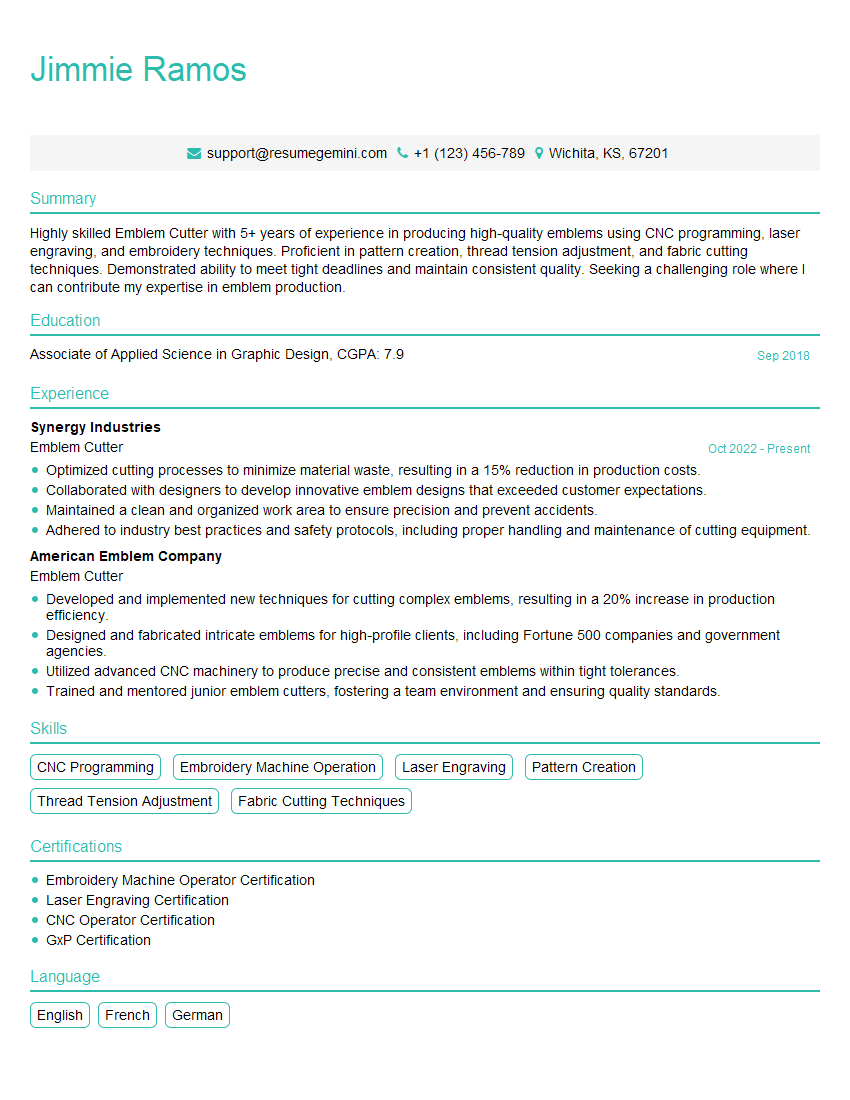

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Emblem Cutter

1. What are the different types of engraving techniques that can be used for emblems?

- Laser engraving: This is a precise and versatile technique that can be used to create intricate designs on a variety of materials, including metal, wood, plastic, and glass.

- Rotary engraving: This technique uses a rotating cutter to create designs in metal or plastic.

- Chemical etching: This technique uses acid to etch designs into metal or glass.

- Embossing: This technique uses a die to create raised designs on metal or paper.

- Debossing: This technique uses a die to create recessed designs on metal or paper.

2. What are the key considerations when choosing an engraving technique for an emblem?

Factors to consider:

- The material of the emblem

- The desired level of detail

- The budget for the project

- The turnaround time

Example:

- For a high-quality emblem with intricate details, laser engraving or rotary engraving would be a good choice.

- For a more budget-friendly option, chemical etching or embossing could be used.

3. What are the most common materials used for emblems?

- Metal: Metal is a durable and versatile material that can be used to create a variety of emblem designs.

- Wood: Wood is a natural material that can be used to create rustic or elegant emblems.

- Plastic: Plastic is a lightweight and affordable material that can be used to create emblems in a variety of colors and shapes.

- Glass: Glass is a transparent material that can be used to create emblems with a modern or sophisticated look.

- Paper: Paper is a versatile material that can be used to create emblems for a variety of purposes, such as awards, certificates, and invitations.

4. What are the different types of finishes that can be applied to emblems?

- Polished finish: This finish gives the emblem a shiny and reflective surface.

- Brushed finish: This finish gives the emblem a matte and textured surface.

- Antiqued finish: This finish gives the emblem a vintage or aged look.

- Painted finish: This finish can be used to add color and detail to the emblem.

- Enameled finish: This finish is a type of paint that is baked onto the emblem, creating a durable and glossy surface.

5. What are the quality control standards that you follow when creating emblems?

Quality Control Standards:

- Inspecting the material for defects

- Ensuring that the engraving is accurate and detailed

- Checking the finish for any imperfections

- Packaging the emblem securely to prevent damage

Example:

- We use a magnifying glass to inspect the engraving for any errors.

- We use a micrometer to measure the thickness of the metal to ensure that it meets our specifications.

- We package the emblems in bubble wrap and cardboard boxes to protect them from damage during shipping.

6. What is your experience with using different types of engraving machines?

Rotary Engraving Machine:

- Used a rotary engraving machine to create intricate designs on metal emblems.

- Familiar with the different types of cutter bits and how to use them to achieve different effects.

- Able to operate the machine safely and efficiently.

Laser Engraving Machine:

- Used a laser engraving machine to create detailed designs on wood and plastic emblems.

- Understand the different laser settings and how to use them to achieve different results.

- Able to operate the machine safely and maintain it properly.

7. How do you ensure that the emblems you create meet the customer’s specifications?

Communication with Customer:

- Clarifying the customer’s requirements and expectations

- Discussing different design options and materials

- Providing samples for approval before production

Attention to Detail:

- Paying close attention to the customer’s specifications

- Inspecting the emblems carefully before delivery

- Making any necessary adjustments to ensure satisfaction

8. What is your experience with working with different types of clients?

Collaboration with Customers:

- Working with clients from a variety of industries and backgrounds

- Understanding their needs and objectives

- Providing them with tailored solutions

Building Relationships:

- Establishing and maintaining long-term relationships with clients

- Providing excellent customer service

- Going above and beyond to meet their expectations

9. How do you stay up-to-date on the latest trends and technologies in the emblem industry?

Industry Research:

- Reading industry publications and attending trade shows

- Exploring new materials and techniques

- Networking with other professionals in the field

Continuous Learning:

- Taking courses and workshops to enhance skills

- Experimenting with new technologies

- Seeking opportunities to learn from experienced colleagues

10. What are your strengths and weaknesses as an Emblem Cutter?

Strengths:

- Skilled in using various engraving techniques

- Strong attention to detail and accuracy

- Excellent customer service skills

- Ability to work independently and as part of a team

- Passionate about creating high-quality emblems

Weaknesses:

- Limited experience with certain types of materials

- Sometimes perfectionistic, which can lead to delays

- Not always comfortable with working under pressure

- Open to feedback and eager to improve

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Emblem Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Emblem Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Emblem Cutters are responsible for creating and producing emblems, which are ornamental designs or symbols that are often used on flags, uniforms, and other items. Their key job responsibilities include:

1. Designing and Creating Emblems

Emblem Cutters design and create emblems based on customer specifications. They use a variety of tools and techniques to create emblems, including hand tools, engraving machines, and computer-aided design (CAD) software.

- Create original emblem designs or modify existing designs to meet customer specifications.

- Use hand tools, engraving machines, and computer-aided design (CAD) software to create emblems.

2. Producing Emblems

Emblem Cutters produce emblems using a variety of materials, including metal, wood, plastic, and fabric. They use a variety of processes to produce emblems, including stamping, engraving, and embroidery.

- Select and prepare materials such as metal, wood, plastic, and fabric for emblem production.

- Use stamping, engraving, and embroidery techniques to produce emblems.

3. Inspecting and Testing Emblems

Emblem Cutters inspect and test emblems to ensure that they meet customer specifications. They check for defects and ensure that the emblems are properly made.

- Inspect and test emblems to ensure they meet quality standards and customer specifications.

- Identify and correct defects in emblems.

4. Maintaining Equipment

Emblem Cutters maintain equipment used in the production of emblems. They clean and calibrate equipment and perform minor repairs.

- Clean and calibrate equipment used in emblem production.

- Perform minor repairs and maintenance on equipment.

Interview Tips

Preparing for an interview for an Emblem Cutter position can help you make a great impression on the interviewer. Here are some tips to help you ace the interview:

1. Research the Company and Position

Before your interview, take the time to research the company and the Emblem Cutter position. This will help you understand the company’s culture and the specific requirements of the job.

- Visit the company’s website and social media pages.

- Read industry publications and news articles about the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

- Prepare a brief introduction of yourself, including your skills and experience.

- Highlight your interest in the Emblem Cutter position and why you are a good fit for the company.

3. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions to ask the interviewer, such as “What are the biggest challenges facing the company?” or “What is the company’s culture like?”

- Ask questions about the company, the position, and the industry.

- Show that you are engaged and interested in the opportunity.

4. Dress Professionally and Arrive on Time

First impressions matter, so make sure to dress professionally for your interview. Arrive on time for your interview and be polite and respectful to everyone you meet.

- Wear a suit or business casual attire.

- Be punctual and arrive on time for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Emblem Cutter interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.