Are you gearing up for a career in Embosser? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Embosser and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

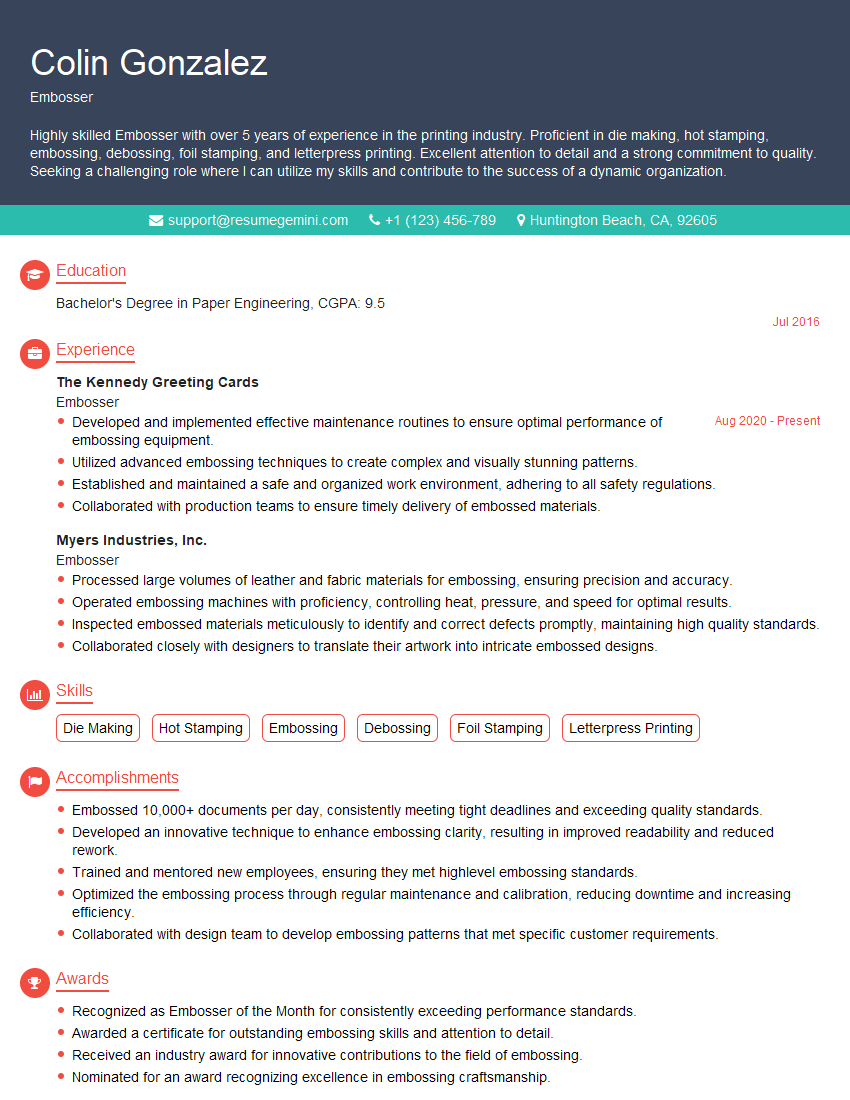

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Embosser

1. What are the different types of embossing machines?

- Hand-operated embossers: These machines are manually operated and require the use of a hammer or mallet to create the embossed design.

- Electric embossers: These machines use an electric motor to power the embossing process. They offer greater precision and control than hand-operated machines.

- Hydraulic embossers: These machines use hydraulic pressure to create the embossed design. They are typically used for large-scale embossing operations.

- Pneumatic embossers: These machines use compressed air to create the embossed design. They offer high precision and speed.

2. What are the different types of embossing dies?

- Flat dies: These dies are used to create simple, two-dimensional designs.

- Raised dies: These dies are used to create three-dimensional designs.

- Indented dies: These dies are used to create recessed designs.

- Combination dies: These dies combine elements of flat, raised, and indented dies to create complex designs.

3. What are the different factors that affect the quality of an embossed design?

- The type of embossing machine

- The type of embossing die

- The material being embossed

- The depth of the embossing

- The speed of the embossing process

4. What are the different applications of embossing?

- Creating decorative patterns on paper, leather, fabric, and other materials

- Producing embossed logos and designs on products such as jewelry, awards, and plaques

- Creating raised lettering on signs and documents

5. What are the safety precautions that need to be taken when operating an embossing machine?

- Wear gloves and safety glasses to protect hands and eyes from injury.

- Ensure that the machine is properly grounded to prevent electrical shock.

- Keep hands and fingers away from moving parts.

- Do not operate the machine if it is damaged or malfunctioning.

6. What are the common problems that can occur during embossing and how can you troubleshoot them?

- Problem: The embossed design is not clear or sharp. Solution: Check the embossing die for damage or wear and replace it if necessary. Increase the depth of the embossing or slow down the embossing speed.

- Problem: The material being embossed is tearing or breaking. Solution: Use a thicker or more durable material. Reduce the depth of the embossing or slow down the embossing speed.

- Problem: The embossing machine is making a strange noise or vibrating excessively. Solution: Check the machine for any loose or damaged parts. Lubricate the machine according to the manufacturer’s instructions.

7. What is the difference between embossing and debossing?

- Embossing creates a raised design on the surface of the material, while debossing creates a recessed design.

- Embossing is typically used for decorative purposes, while debossing is often used for branding or creating raised lettering.

8. What are the advantages of using embossing over other printing techniques?

- Embossing creates a tactile and visually appealing design that can add value to a product.

- Embossing is a relatively inexpensive printing technique that can be used on a variety of materials.

- Embossed designs are durable and can withstand wear and tear.

9. What are the challenges of working as an embosser?

- Embossing can be a physically demanding job, as it requires the use of heavy equipment and materials.

- Embossers must have a keen eye for detail and be able to produce high-quality designs.

- Embossers must be able to work quickly and efficiently to meet production deadlines.

10. What are your career goals as an embosser?

- I would like to develop my skills and become a master embosser.

- I would like to work on a variety of projects and learn about different embossing techniques.

- I would like to eventually start my own embossing business.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Embosser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Embosser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Embossers are responsible for creating raised designs on a variety of materials, including paper, plastic, and metal. They use a variety of techniques, including hand-embossing, machine-embossing, and hot-stamping, to create intricate and detailed designs.

1. Hand-embossing

This is the most traditional method of embossing, and it involves using a hammer and chisel to create a design on the surface of the material.

- Use a hammer and chisel to create a design on the surface of the material.

- Hold the chisel at a 45-degree angle to the surface of the material.

- Tap the chisel with the hammer to create a raised design.

2. Machine-embossing

This method uses a machine to create a design on the surface of the material. The machine can be either manual or automated, and it uses a variety of dies to create different designs.

- Set up the machine according to the manufacturer’s instructions.

- Load the material into the machine.

- Start the machine and allow it to create the design on the material.

3. Hot-stamping

This method uses heat to create a design on the surface of the material. A heated die is pressed against the material, and the heat causes the material to soften and conform to the shape of the die. The design can then be removed from the material.

- Heat the die to the desired temperature.

- Place the material on the die.

- Press the die against the material for a few seconds.

- Remove the die and allow the material to cool.

4. Quality Control

In addition to creating designs, embossers are also responsible for quality control. They inspect the finished products to ensure that they meet the required standards.

- Inspect the finished products to ensure that they meet the required standards.

- Identify and correct any defects in the finished products.

- Maintain a clean and organized work area.

Interview Tips

Preparing for an embosser interview can be daunting, but with the right tips, you can increase your chances of success.

1. Research the company and the position

Before you go to the interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture, the job requirements, and the interviewer’s expectations.

- Visit the company’s website.

- Read online reviews of the company.

- Talk to people who work for the company.

2. Prepare your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”. Practice answering these questions in advance so that you can deliver confident and articulate responses.

- Write down your answers to common interview questions.

- Practice answering these questions out loud.

- Get feedback from a friend or family member.

3. Bring your portfolio

If you have a portfolio of your work, bring it to the interview. This will give the interviewer a chance to see your skills and experience firsthand.

- Create a portfolio that showcases your best work.

- Include a variety of projects that demonstrate your skills in different areas.

- Be prepared to talk about your portfolio in detail.

4. Dress professionally

First impressions matter, so make sure to dress professionally for your interview. This means wearing a suit or business casual attire.

- Wear a suit or business casual attire.

- Make sure your clothes are clean and pressed.

- Accessorize with a tie or scarf.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Embosser interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!