Feeling lost in a sea of interview questions? Landed that dream interview for Embossing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Embossing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

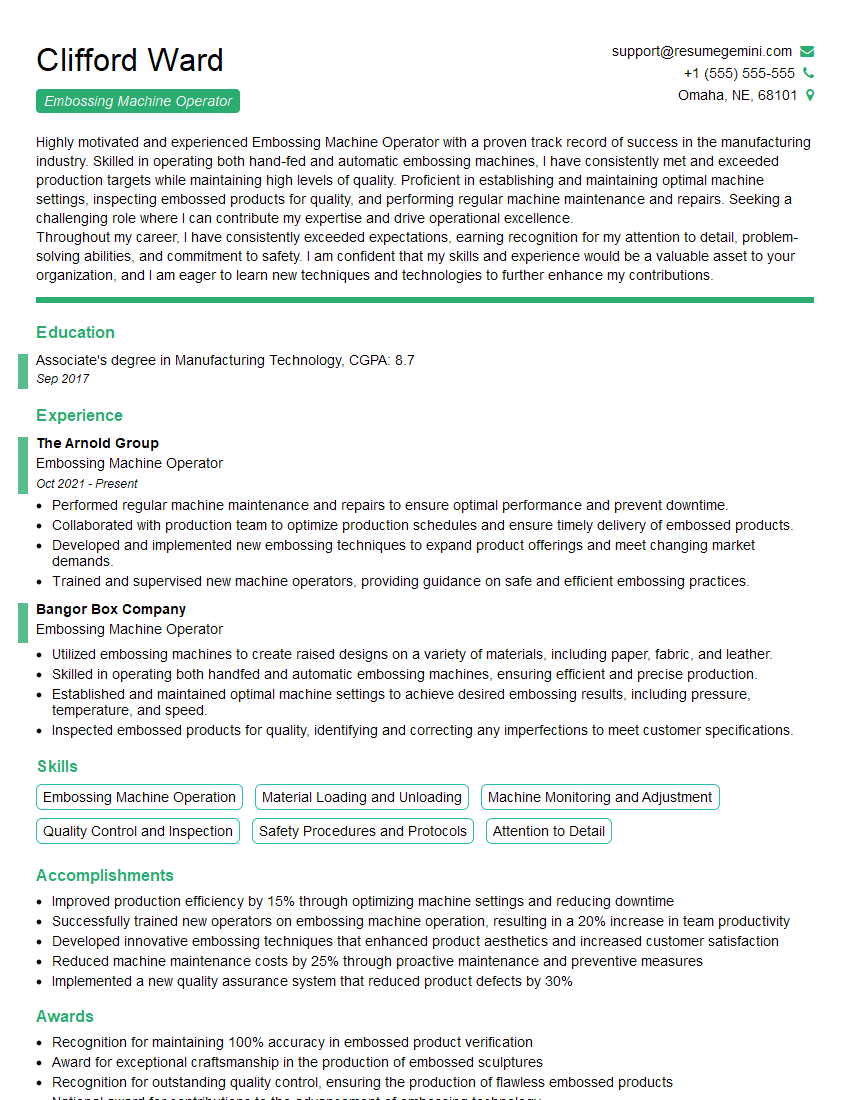

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Embossing Machine Operator

1. Describe the process of setting up an embossing machine for a specific job?

- First, I would need to gather the necessary materials, which include the embossing machine, the die, the substrate, and any necessary adhesives.

- Next, I would need to set up the machine according to the manufacturer’s instructions.

- This would involve mounting the die on the machine, setting the pressure and temperature, and feeding the substrate through the machine.

- Once the machine is set up, I would need to test it on a scrap piece of material to ensure that it is working properly.

- Once I am satisfied that the machine is working properly, I would begin embossing the substrate.

- I would need to feed the substrate through the machine evenly and at a consistent speed.

- I would also need to monitor the pressure and temperature to ensure that the embossing is done correctly.

2. What are the different types of dies used in embossing?

- There are many different types of dies used in embossing, each with its own unique purpose.

- The most common type of die is the flat die, which is used to create a raised or recessed image on the substrate.

- Other types of dies include rotary dies, which are used to create continuous patterns, and transfer dies, which are used to transfer an image from one substrate to another.

- The type of die used will depend on the desired result.

3. What are the different materials that can be embossed?

- A variety of materials can be embossed, including paper, plastic, metal, and leather.

- The type of material used will depend on the desired result.

- For example, paper is often used for embossing invitations and stationery, while metal is often used for embossing jewelry and other decorative items.

4. What are the different types of adhesives used in embossing?

- There are many different types of adhesives used in embossing, each with its own unique properties.

- The most common type of adhesive used is water-based adhesive, which is easy to use and dries quickly.

- Other types of adhesives include solvent-based adhesives, which are more durable but can be more difficult to use, and heat-activated adhesives, which require heat to bond.

- The type of adhesive used will depend on the materials being embossed and the desired result.

5. What are the different factors that affect the quality of an embossed image?

- The quality of an embossed image is affected by a number of factors, including:

- The type of die used

- The type of material being embossed

- The type of adhesive used

- The pressure and temperature used during embossing

- The speed at which the substrate is fed through the machine

- The skill of the operator

6. What are the most common problems that can occur during embossing?

- The most common problems that can occur during embossing include:

- The die becoming stuck in the substrate

- The substrate tearing or wrinkling

- The adhesive not bonding properly

- The embossed image being too faint or too deep

- The machine overheating

7. How do you troubleshoot and resolve problems that occur during embossing?

- If the die becomes stuck in the substrate, I would first try to remove it gently with a pair of tweezers.

- If the substrate tears or wrinkles, I would need to start over with a new piece of material.

- If the adhesive is not bonding properly, I would try using a different type of adhesive or applying more pressure during embossing.

- If the embossed image is too faint or too deep, I would adjust the pressure and temperature settings on the machine.

- If the machine overheats, I would turn it off and allow it to cool down before continuing.

8. What are the safety precautions that should be taken when operating an embossing machine?

- When operating an embossing machine, it is important to take the following safety precautions:

- Always wear safety glasses.

- Never put your hands in the machine while it is running.

- Keep the work area clean and free of debris.

- Be aware of the potential for the machine to overheat.

- Follow all of the manufacturer’s instructions.

9. What are the maintenance procedures that should be performed on an embossing machine?

- To keep an embossing machine in good working order, it is important to perform the following maintenance procedures:

- Clean the machine regularly with a soft cloth.

- Oil the moving parts of the machine on a regular basis.

- Inspect the dies for wear and tear.

- Check the adhesive for proper bonding.

- Follow all of the manufacturer’s instructions for maintenance.

10. What are the different applications for embossing?

- Embossing is used in a variety of applications, including:

- Creating invitations and stationery

- Decorating scrapbook pages

- Making jewelry and other decorative items

- Identifying products and packaging

- Creating raised lettering on signs and plaques

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Embossing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Embossing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Embossing Machine Operators play a pivotal role in the manufacturing industry by utilizing specialized machines to create raised or recessed designs on various materials.

1. Setup and Operation

Operators are responsible for setting up and operating embossing machines ensuring proper alignment and tension of materials.

- Mount and adjust dies and rollers

- Set machine parameters (temperature, pressure, speed)

2. Material Handling

They handle a variety of materials such as paper, plastic, fabric, and leather with care and precision.

- Load and unload materials into machines

- Monitor material flow and adjust as necessary

3. Quality Control

Operators inspect finished products to ensure they meet quality standards and specifications.

- Identify and correct defects

- Maintain records of production and quality

4. Troubleshooting and Maintenance

They identify and resolve minor malfunctions and perform routine maintenance to keep machines operating efficiently.

- Diagnose and repair mechanical and electrical issues

- Clean and lubricate machines

Interview Tips

Preparing thoroughly for an Embossing Machine Operator interview can significantly boost your chances of success.

1. Research the Company and Role

Gain insights into the company’s industry, products, and culture. Understand the specific responsibilities of the role and how they align with your skills and experience.

- Visit the company website and social media pages

- Read industry publications and news articles

2. Highlight Relevant Skills and Experience

Emphasize your technical proficiency in embossing machine operation, material handling, and quality control. Share specific examples of your accomplishments in these areas.

- Quantify your results using specific metrics (e.g., increased production efficiency by 15%)

- Showcase your problem-solving abilities and attention to detail

3. Practice Common Interview Questions

Anticipate common interview questions and prepare thoughtful responses with concrete examples.

- Tell me about your experience operating embossing machines

- How do you ensure the quality of embossed products?

- What are some common troubleshooting steps you perform?

4. Demonstrate Enthusiasm and Motivation

Convey your passion for the industry and your eagerness to contribute to the company’s success.

- Express your interest in new technologies and advancements in embossing techniques

- Show your willingness to learn and take on new challenges

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Embossing Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!