Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Embossing Press Operator Apprentice position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

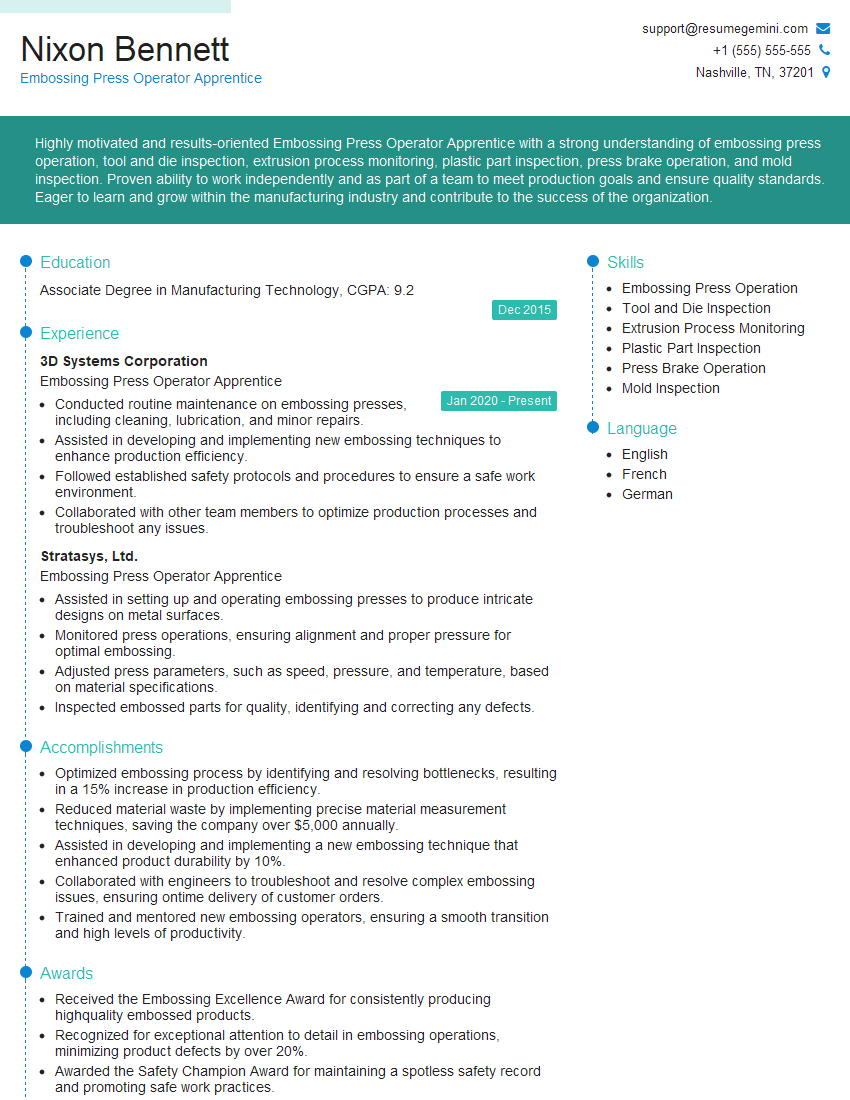

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Embossing Press Operator Apprentice

1. What are the different types of embossing presses and their uses?

- Roll-to-roll embossing press: These presses use two rolls, one with the pattern and one with a backing material, to emboss the material passing through them.

- Flat-bed embossing press: These presses use a flat die with the pattern to emboss the material against a flat backing plate.

- Cylinder embossing press: These presses use a cylinder with the pattern to emboss the material against a flat backing plate.

2. What are the key factors to consider when selecting an embossing press?

Factors to consider when selecting an embossing press:

- The type of material to be embossed

- The desired embossing pattern

- The production volume

- The budget

Additional factors to consider:

- The size of the press

- The speed of the press

- The accuracy of the press

- The ease of use of the press

3. How do you set up and operate an embossing press?

The steps to set up and operate an embossing press may vary depending on the specific press. However, the general steps are as follows:

- Install the die in the press.

- Set the pressure and speed of the press.

- Feed the material into the press.

- Activate the press to emboss the material.

- Remove the embossed material from the press.

4. How do you troubleshoot common problems with embossing presses?

- Problem: The material is not being embossed properly.

- Possible causes: The die is not installed correctly, the pressure is too low, the speed is too low, or the material is too thick.

- Problem: The press is making a lot of noise.

- Possible causes: The bearings are worn out, the gears are not meshing properly, or the press is not properly lubricated.

- Problem: The press is not working at all.

- Possible causes: The power is not turned on, the motor is not working, or the press is not properly wired.

5. What are the safety precautions that should be taken when operating an embossing press?

The following are some of the safety precautions that should be taken when operating an embossing press:

- Wear appropriate safety gear, such as safety glasses, gloves, and earplugs.

- Keep hands and fingers away from the moving parts of the press.

- Do not attempt to operate the press if you are not trained to do so.

- Follow all of the manufacturer’s instructions for safe operation.

6. What are the different types of materials that can be embossed?

A variety of materials can be embossed, including paper, cardboard, plastic, metal, and leather. The type of material that can be embossed will depend on the type of embossing press being used.

7. What are the different types of embossing patterns?

There are many different types of embossing patterns, including geometric patterns, floral patterns, animal patterns, and custom patterns. The type of embossing pattern that is used will depend on the desired look and feel of the embossed material.

8. What are the different applications for embossed materials?

Embossed materials can be used in a variety of applications, including packaging, decoration, and signage. Embossed materials can be used to add a touch of elegance and sophistication to any product or project.

9. What are the advantages of using an embossing press?

There are many advantages to using an embossing press, including:

- Embossing presses can create a variety of patterns and designs.

- Embossing presses can be used to emboss a variety of materials.

- Embossing presses are relatively easy to operate.

- Embossing presses are relatively affordable.

10. What are the disadvantages of using an embossing press?

There are some disadvantages to using an embossing press, including:

- Embossing presses can be large and bulky.

- Embossing presses can be noisy.

- Embossing presses can be dangerous to operate if not used properly.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Embossing Press Operator Apprentice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Embossing Press Operator Apprentice‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Embossing Press Operator Apprentice is responsible for a variety of tasks related to the operation of an embossing press, including:

1. Setup and Operation

Setting up and operating the embossing press according to specifications.

- Loading and unloading materials.

- Adjusting machine settings.

2. Quality Control

Monitoring the quality of the embossed products and making adjustments as needed.

- Inspecting products for defects.

- Taking corrective action to ensure products meet quality standards.

3. Maintenance

Performing basic maintenance on the embossing press.

- Lubricating and cleaning the machine.

- Replacing worn or damaged parts.

4. Safety

Following all safety procedures and regulations.

- Wearing appropriate safety gear.

- Operating the machine in a safe manner.

Interview Tips

Preparing for an interview for an Embossing Press Operator Apprentice position can be a daunting task, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the Company and the Position

Before you even step into the interview, take some time to research the company and the specific position you are applying for. This will give you a better understanding of the company’s culture, values, and goals, as well as the specific requirements of the job.

- Visit the company’s website.

- Read online reviews of the company.

- Talk to people who work or have worked for the company.

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?”. It is important to practice your answers to these questions so that you can deliver them confidently and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on your skills and experience that are relevant to the job.

- Be prepared to provide specific examples of your work.

3. Be Prepared to Ask Questions

Asking questions at the end of an interview shows that you are interested in the position and the company. It also gives you an opportunity to learn more about the job and the company culture.

- Prepare a list of questions to ask the interviewer.

- Ask questions that are specific to the job and the company.

- Be prepared to answer questions about your own career goals.

4. Dress Professionally and Arrive on Time

First impressions matter, so it is important to dress professionally for your interview. You should also arrive on time, as being late can reflect poorly on you.

- Wear a suit or business casual attire.

- Be well-groomed and make sure your clothes are clean and pressed.

- Plan your route to the interview in advance so that you can avoid getting lost or being late.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Embossing Press Operator Apprentice interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.