Are you gearing up for an interview for a Emery Grinder position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Emery Grinder and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

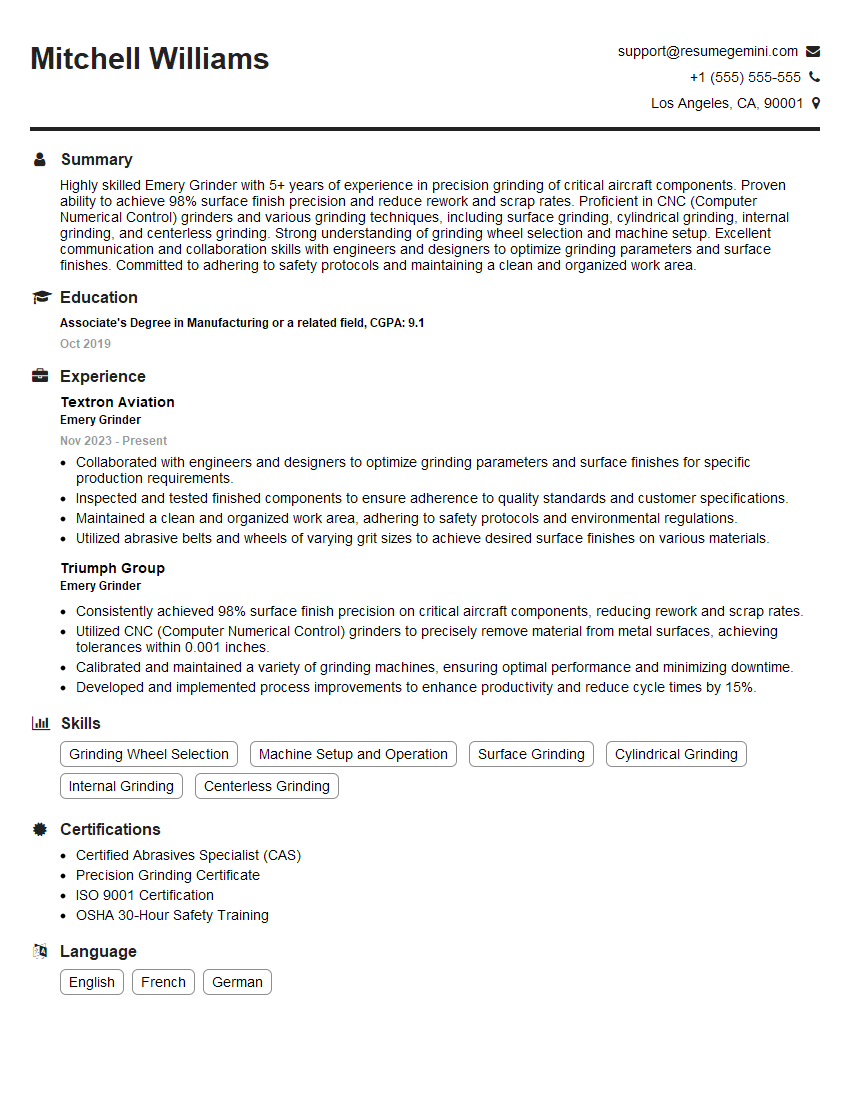

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Emery Grinder

1. What are the different types of grinding wheels and their applications?

- Diamond wheels: Used for grinding hard materials such as ceramics, glass, and gemstones.

- Cubic boron nitride (CBN) wheels: Used for grinding hardened steels and other hard materials.

- Aluminum oxide wheels: Used for grinding a wide range of materials, including metals, plastics, and wood.

- Silicon carbide wheels: Used for grinding hard materials such as stone, concrete, and ceramics.

- Ceramic wheels: Used for grinding a wide range of materials, including metals, plastics, and composites.

2. What are the factors to consider when selecting a grinding wheel?

Factors to consider when selecting a grinding wheel

- The material being ground

- The desired surface finish

- The operating speed of the grinder

- The size and shape of the workpiece

- The type of grinding operation (e.g., surface grinding, cylindrical grinding, etc.)

subheading of the answer

- By considering these factors, you can select the grinding wheel that is best suited for your specific application.

- For example, if you are grinding a hard material such as steel, you would choose a diamond or CBN wheel.

- If you are grinding a soft material such as wood, you would choose an aluminum oxide or silicon carbide wheel.

3. What are the different types of grinding machines and their applications?

- Surface grinders: Used for grinding flat surfaces.

- Cylindrical grinders: Used for grinding cylindrical surfaces.

- Centerless grinders: Used for grinding workpieces without the use of centers.

- Internal grinders: Used for grinding the inside of holes.

- Tool and cutter grinders: Used for grinding cutting tools and other tools.

4. What are the safety precautions that must be taken when operating a grinding machine?

- Always wear the appropriate safety gear, including goggles, gloves, and a respirator.

- Make sure the grinding machine is properly guarded and that the workpiece is securely clamped.

- Never operate a grinding machine that is not in good working condition.

- Be aware of the potential for sparks and flying debris.

- Always follow the manufacturer’s instructions for operating the grinding machine.

5. What are the common problems that can occur when grinding and how can they be solved?

- Chattering: This can be caused by a number of factors, including an unbalanced grinding wheel, a workpiece that is not securely clamped, or a grinding machine that is not in good working condition. To solve this problem, check the balance of the grinding wheel, make sure the workpiece is securely clamped, and ensure that the grinding machine is in good working condition.

- Burning: This can be caused by using a grinding wheel that is too hard for the material being ground, or by grinding at too high a speed. To solve this problem, use a grinding wheel that is less hard and grind at a slower speed.

- Glazing: This can be caused by using a grinding wheel that is too soft for the material being ground, or by grinding at too low a speed. To solve this problem, use a grinding wheel that is harder and grind at a higher speed.

6. What are the different types of coolants used in grinding and what are their advantages and disadvantages?

- Water-based coolants: These are the most common type of coolant used in grinding. They are inexpensive and readily available. However, they can cause rust and corrosion on the workpiece and the grinding machine.

- Oil-based coolants: These coolants are less likely to cause rust and corrosion than water-based coolants. However, they are more expensive and can be more difficult to dispose of.

- Synthetic coolants: These coolants are designed to provide the best of both worlds. They are less likely to cause rust and corrosion than water-based coolants and they are less expensive than oil-based coolants.

7. What are the different types of grinding fluids and what are their applications?

- Straight oils: These are unadulterated oils, such as mineral oil or vegetable oil. They are used for light-duty grinding operations and provide good lubrication and cooling.

- Soluble oils: These are oils that have been mixed with water. They are used for medium-duty grinding operations and provide good lubrication, cooling, and rust protection.

- Synthetic fluids: These are fluids that have been specifically designed for grinding operations. They are used for heavy-duty grinding operations and provide excellent lubrication, cooling, and rust protection.

8. What are the different types of grinding wheels and how are they used?

- Abrasive wheels: These wheels are made from a variety of abrasive materials, such as aluminum oxide, silicon carbide, and diamond. They are used for grinding a wide range of materials, from metals to plastics.

- Bonded wheels: These wheels are made from abrasive materials that are bonded together with a binder, such as resin or ceramic. They are used for heavy-duty grinding operations.

- Coated wheels: These wheels are made from abrasive materials that are coated onto a backing material, such as paper or cloth. They are used for light-duty grinding operations.

9. What are the different types of grinding machines and how are they used?

- Surface grinders: These machines are used to grind flat surfaces. They have a rotating grinding wheel that moves across the surface of the workpiece.

- Cylindrical grinders: These machines are used to grind cylindrical surfaces. They have a rotating grinding wheel that moves around the workpiece.

- Centerless grinders: These machines are used to grind workpieces without the use of centers. They have two grinding wheels that rotate in opposite directions.

10. What are the different types of grinding processes and how are they used?

- Conventional grinding: This is the most common type of grinding process. It uses a rotating grinding wheel to remove material from the workpiece.

- Creep feed grinding: This process uses a slowly rotating grinding wheel to remove material from the workpiece. It is used to produce high-quality surfaces.

- High-speed grinding: This process uses a high-speed rotating grinding wheel to remove material from the workpiece. It is used to produce high-production rates.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Emery Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Emery Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Emery Grinder’s primary undertaking is to meticulously shape, grind, and polish a wide spectrum of workpieces employing an emery wheel as their tool of choice. The skillful execution of this task demands precision and expertise in order to achieve accurate dimensions, eliminate burrs, and impart a smooth finish.

1. Material Handling

An Emery Grinder’s adept handling of materials is paramount in ensuring the seamless execution of tasks and the preservation of workplace safety.

- Properly secures the workpiece on the grinder’s table or fixture for unwavering stability and precision during operation.

- Accurately positions the workpiece relative to the emery wheel to achieve desired results.

2. Grinding and Polishing

With deft precision, Emery Grinders meticulously shape and refine workpieces using the emery wheel’s abrasive surface.

- Skilfully operates the emery wheel, applying the appropriate pressure and motion to achieve precise dimensions and a smooth finish.

- Expertly employs various techniques to grind, deburr, and polish workpieces, tailoring the process to the specific material and desired outcome.

3. Inspection and Measurement

An Emery Grinder’s keen eye for detail ensures that workpieces meet exacting specifications.

- Meticulously inspects workpieces throughout the grinding and polishing process to verify conformity with blueprints and quality standards.

- Utilizes precision measuring instruments to ensure accurate dimensions, ensuring that workpieces adhere to specified tolerances.

4. Equipment Maintenance

The upkeep of equipment is an integral aspect of an Emery Grinder’s role, ensuring optimal performance and longevity.

- Regularly inspects and cleans the emery wheel, dressing it as needed to maintain its abrasive properties.

- Conducts routine maintenance on the grinder, including lubrication, belt changes, and other essential tasks.

Interview Tips

To prepare for an Emery Grinder interview, it is imperative to showcase your proficiency in the key job responsibilities outlined above. Additionally, the following tips will help you ace the interview:

1. Research and Preparation

Invest time in thoroughly researching the company, the specific industry, and the role of an Emery Grinder. This will demonstrate your enthusiasm for the opportunity and provide you with valuable insights to draw upon during the interview.

- Familiarize yourself with the company’s products, services, and industry standing.

- Research the role’s responsibilities, as well as the company’s expectations for the position.

2. Highlight Relevant Skills and Experience

Emphasize your proficiency in the key job responsibilities, providing specific examples to illustrate your abilities.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your responses to the specific requirements of the role, highlighting the skills and experience that are most relevant to the position.

3. Practice Common Interview Questions

Prepare for common interview questions by rehearsing your answers and practicing articulation.

- Anticipate questions about your experience, skills, and qualifications.

- Craft thoughtful and concise answers that showcase your strengths and enthusiasm for the role.

4. Professionalism and Etiquette

Maintain a professional demeanor throughout the interview, demonstrating respect and enthusiasm.

- Dress appropriately and arrive on time for your interview.

- Maintain eye contact, speak clearly, and actively listen to the interviewer’s questions.

Next Step:

Now that you’re armed with the knowledge of Emery Grinder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Emery Grinder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini