Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Enameler position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

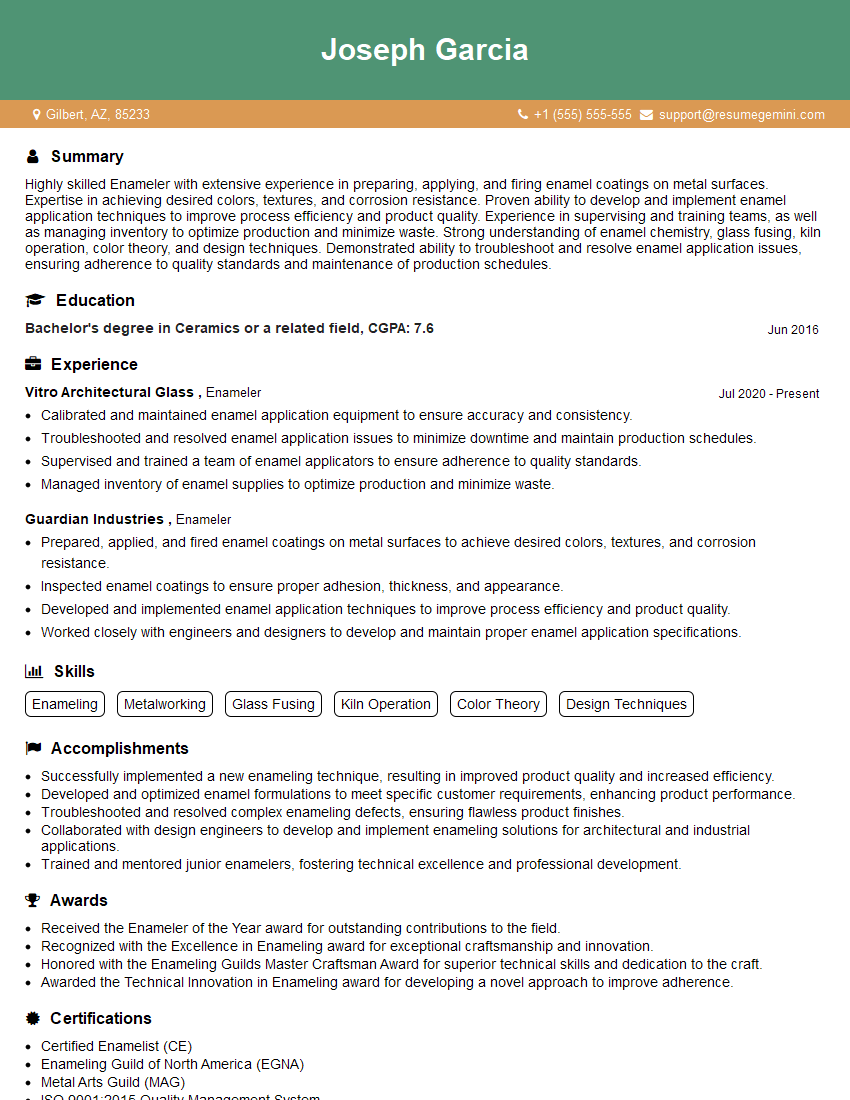

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Enameler

1. How do you prepare the metal surface for enamelling?

To prepare the metal surface for enamelling, I follow a rigorous process:

- Cleaning: I thoroughly clean the metal surface using solvents, detergents, or ultrasonic cleaners to remove any dirt, grease, or oxides.

- Sandblasting: I create a rough surface for better adhesion by sandblasting the metal with fine grit media.

- Pickling: I immerse the metal in an acidic solution (e.g., hydrochloric acid) to remove any remaining oxides or impurities.

- Fluxing: I apply a thin layer of flux (a chemical composition) to promote adhesion between the metal and enamel.

2. What are the different types of enamels available?

Vitreous Enamels

- Cloisonné: Cells are created on the metal, and enamel is applied within the cells.

- Champlevé: The enamel is recessed into the metal, creating a raised effect.

- Painted: Enamel is applied directly onto the metal surface and fired.

- Overglaze: Enamel is applied over an existing fired glaze layer.

Non-Vitreous Enamels

- Cold Enamels: Resin-based enamels that can be applied at room temperature.

3. How do you select the appropriate enamel for a project?

I consider several factors when selecting the appropriate enamel:

- Type of metal: Different metals have different compatibility with enamels.

- Desired finish: The enamel’s translucency, colour, and texture should match the desired aesthetic.

- Firing temperature: The enamel’s firing temperature must be compatible with the metal’s melting point.

- Budget: Different enamels have varying costs, depending on the materials and techniques used.

4. What are the common defects that can occur in enamelling?

- Blistering: Trapped gases in the enamel cause bubbles or blisters.

- Crazing: Fine cracks in the enamel surface due to thermal expansion differences.

- Crawling: Enamel retracts from the metal surface, leaving bare areas.

- Flux burn: Excessive flux can cause discolouration or pitting of the enamel.

- Pinholing: Tiny holes in the enamel surface due to gas bubbles or impurities.

5. How do you troubleshoot and correct common defects in enamelling?

- Blistering: Reduce firing temperature, ensure proper drying before firing, and check for trapped air pockets.

- Crazing: Control firing temperature and ramp, match enamel coefficient of expansion to metal, and use a flux with the correct composition.

- Crawling: Clean the metal surface thoroughly, apply flux evenly, and ensure the enamel is not too thick.

- Flux burn: Use the correct flux type and quantity, and remove excess flux before firing.

- Pinholing: Check the enamel consistency, remove impurities, and fire at a lower temperature.

6. What are the safety precautions that must be followed when enamelling?

- Wear protective clothing, including gloves, apron, and mask.

- Ensure proper ventilation in the workspace.

- Handle acidic solutions and fluxes with care.

- Use appropriate firing equipment and follow safety guidelines.

- Beware of hot surfaces and molten enamel.

7. What are the different techniques used for applying enamel?

- Dry Sifting: Enamel powder is sprinkled onto the metal surface.

- Wet Packing: Enamel powder is mixed with water and applied as a paste.

- Slurry: Enamel powder is mixed with oil or wax and applied with a brush or pipette.

- Screen Printing: Enamel powder is applied through a stencil using a screen.

- Airbrushing: Enamel powder is mixed with water and applied using an airbrush.

8. How do you fire enamel and what are the key parameters to control?

Enamel firing involves heating the enamel to a specific temperature and holding it for a defined duration:

- Temperature: Enamels have specific firing temperatures, which must be precisely controlled to ensure proper melting and adhesion.

- Time: Enamels require sufficient time at the firing temperature to fully vitrify and bond with the metal.

- Atmosphere: The firing atmosphere (e.g., oxidising or reducing) can affect the enamel’s colour and properties.

- Cooling: Controlled cooling after firing is essential to prevent cracking or stress fractures.

9. What are the different types of kilns used for enamelling?

- Electric Kilns: Versatile and commonly used, offering precise temperature control.

- Gas Kilns: Provide high temperatures but require more expertise to operate.

- Microwaves: Suitable for small-scale enamelling, but require specialised equipment.

10. How do you maintain and calibrate your enamelling equipment?

- Kilns: Regular cleaning, thermocouple calibration, and electrical safety checks.

- Balances: Calibrated regularly to ensure accurate weighing of enamel powders.

- Grinders and Polishers: Maintained sharp and clean for optimal surface preparation.

- Ventilation System: Ensured to be in good working order for proper fume extraction.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Enameler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Enameler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Enamelers are responsible for applying a thin layer of glass to metal surfaces, creating a durable and decorative finish. They work in various industries, including jewelry, tableware, and architecture, and their tasks can include:

1. Preparing the Metal Surface

Enamelers begin by preparing the metal surface by cleaning and degreasing it. They may also apply a layer of primer to help the enamel adhere.

2. Applying the Enamel

Enamelers can apply enamel in various ways, such as brushing, dipping, or spraying. They use specialized techniques to ensure an even, smooth application.

3. Firing the Enamel

Once the enamel has been applied, it must be fired in a kiln. This high-temperature process fuses the enamel to the metal, creating a permanent bond.

4. Cooling and Finishing

After firing, the enameled piece must be allowed to cool slowly to prevent cracking. Enamelers may also perform additional finishing touches, such as polishing or carving.

Interview Tips

Preparing for an enameler interview requires a combination of technical knowledge and communication skills. Here are some tips:

1. Research the Company and Industry

Learn about the company’s products, services, and the specific role you’re applying for. Familiarity with the industry’s trends and best practices will also impress interviewers.

2. Highlight Your Technical Expertise

Discuss your proficiency in enamel application techniques, kiln operation, and metalworking skills. Provide specific examples of your ability to create high-quality enameled pieces.

3. Showcase Your Artistic Abilities

Enameling requires a keen eye for detail and a creative flair. Prepare examples of your work that demonstrate your artistic abilities and your ability to bring design concepts to life.

4. Emphasize Your Communication Skills

Enamelers often collaborate with designers, engineers, and clients. Strong communication and interpersonal skills are essential for effective collaboration and building relationships.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Enameler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!