Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the End Maker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a End Maker so you can tailor your answers to impress potential employers.

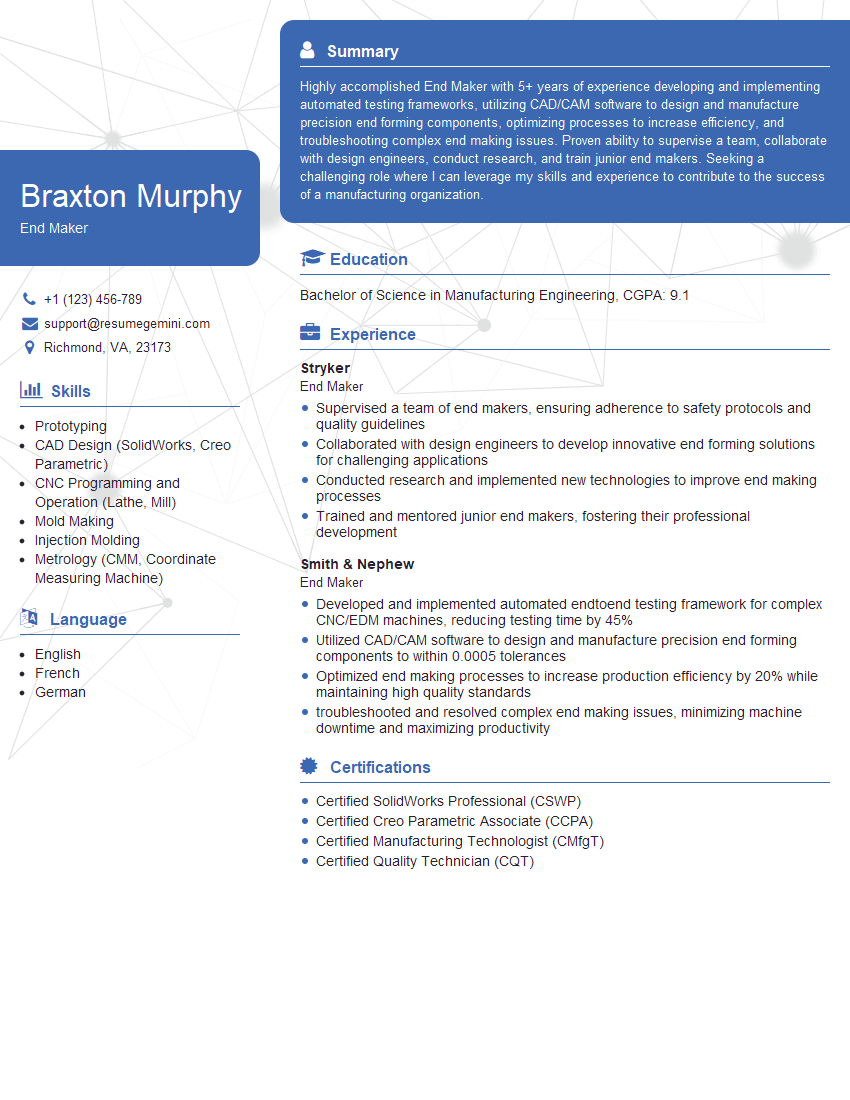

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For End Maker

1. What is the difference between a 3-axis and a 5-axis CNC machine?

- A 3-axis CNC machine can move the cutting tool in three directions: X, Y, and Z.

- A 5-axis CNC machine can move the cutting tool in five directions: X, Y, Z, A, and B.

- The additional two axes of movement (A and B) on a 5-axis CNC machine allow for more complex machining operations, such as contouring and undercutting.

- 5-axis CNC machines are more expensive than 3-axis CNC machines, but they can produce more complex parts with higher accuracy.

2. What are the different types of CNC controls?

G-Code

- G-code is a programming language used to control CNC machines.

- G-code programs are typically generated by CAM software.

- G-code programs contain instructions for the CNC machine, such as the position of the cutting tool, the feed rate, and the spindle speed.

Conversational

- Conversational CNC controls are user-friendly and easy to learn.

- Conversational CNC controls use a graphical user interface (GUI) to guide the user through the programming process.

- Conversational CNC controls are typically used for simple machining operations.

3. What are the different types of cutting tools used in CNC machining?

- End mills

- Drill bits

- Taps

- Dies

- Reamers

- Boring bars

- Knurling tools

- The type of cutting tool used depends on the machining operation being performed.

4. What is the difference between a collet and a chuck?

- A collet is a type of workholding device used to hold a cutting tool in a CNC machine.

- Collets are typically used to hold small-diameter cutting tools.

- A chuck is another type of workholding device used to hold a cutting tool in a CNC machine.

- Chucks are typically used to hold large-diameter cutting tools.

- Collets are more precise than chucks, but chucks are more versatile.

5. What is the difference between a roughing cut and a finishing cut?

Roughing cut

- A roughing cut is a machining operation that removes a large amount of material from a workpiece.

- Roughing cuts are typically performed with a large-diameter cutting tool.

- Roughing cuts are not as precise as finishing cuts.

Finishing cut

- A finishing cut is a machining operation that removes a small amount of material from a workpiece to achieve the desired surface finish.

- Finishing cuts are typically performed with a small-diameter cutting tool.

- Finishing cuts are more precise than roughing cuts.

6. What is the purpose of a coolant in CNC machining?

- A coolant is a liquid that is used to cool the cutting tool and the workpiece during CNC machining.

- Coolants help to reduce friction and heat, which can extend the life of the cutting tool and improve the surface finish of the workpiece.

- Coolants can also help to remove chips from the cutting area.

7. What is the difference between a tapered end mill and a ball end mill?

- A tapered end mill has a conical shape, with the diameter of the cutting tool decreasing from the shank to the tip.

- Tapered end mills are used for machining tapered holes and slots.

- A ball end mill has a spherical shape, with the cutting tool having a radius at the tip.

- Ball end mills are used for machining curved surfaces and pockets.

8. What is the difference between a pocket and a cavity?

- A pocket is a machined recess in a workpiece that has a closed bottom.

- Pockets are typically used to hold bearings or other components.

- A cavity is a machined recess in a workpiece that has an open bottom.

- Cavities are typically used to reduce the weight of a workpiece or to provide access to internal components.

9. What is the difference between a thread mill and a tap?

- A thread mill is a cutting tool that is used to machine threads in a workpiece.

- Thread mills are typically used for machining internal threads.

- A tap is a cutting tool that is used to machine threads in a workpiece by hand or with a machine.

- Taps are typically used for machining external threads.

10. What is the difference between a chamfer and a radius?

- A chamfer is a beveled edge on a workpiece.

- A radius is a curved edge on a workpiece.

- Chamfers are typically used to remove sharp edges or to improve the appearance of a workpiece.

- Radii are typically used to improve the strength or durability of a workpiece.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for End Maker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the End Maker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

End Maker plays a crucial role in the manufacturing process, ensuring the smooth and efficient production of finished goods. Their responsibilities span various aspects of the production line, from setting up and operating machinery to quality control and troubleshooting.

1. Machine Operation and Setup

End Makers are responsible for setting up and operating a variety of machines, including automated assembly lines, conveyor systems, and testing equipment. They must ensure that the machines are properly calibrated and adjusted to produce high-quality products.

- Setting up and adjusting machines according to specifications

- Monitoring machine performance and making necessary adjustments

2. Product Assembly and Inspection

End Makers play a key role in assembling and inspecting finished products. They ensure that products meet quality standards and are free from defects. They also perform final assembly tasks, such as attaching labels, packaging, and testing products.

- Assembling products according to specifications

- Inspecting products for defects and verifying compliance with standards

3. Process Improvement and Troubleshooting

End Makers are actively involved in identifying and resolving production issues. They analyze production data, identify bottlenecks, and implement solutions to improve efficiency and reduce waste. They also troubleshoot machine malfunctions and develop preventive maintenance plans.

- Analyzing production data to identify areas for improvement

- Implementing process improvements to increase efficiency and reduce costs

4. Quality Control and Compliance

End Makers are responsible for maintaining high levels of product quality. They perform regular quality checks to ensure that products meet specifications and comply with industry standards. They also work closely with quality control personnel to identify and address any quality issues.

- Performing quality checks on finished products

- Ensuring compliance with industry standards and regulations

Interview Tips

Preparing thoroughly for an End Maker interview can significantly increase your chances of success. Here are some tips and hacks to help you ace the interview:

1. Research the Company and Industry

Familiarize yourself with the company’s website, products, and industry trends. This knowledge will demonstrate your interest in the role and the company’s mission.

- Visit the company’s website to learn about their history, products, and culture.

- Research industry-specific publications and news articles to stay up-to-date on current trends.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as “Tell me about yourself,” “Why are you interested in this role?,” and “What are your strengths and weaknesses?” Practice delivering your answers clearly and concisely.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Focus on highlighting your relevant skills and experiences.

3. Showcase Your Technical Skills

End Makers are expected to have a strong understanding of manufacturing processes and machinery. If possible, mention specific software or equipment you have worked with in your previous roles.

- Be prepared to discuss your experience with automated assembly lines, conveyor systems, and testing equipment.

- Highlight your proficiency in quality control techniques and industry standards.

4. Emphasize Your Problem-Solving Abilities

End Makers often encounter production issues that require quick and effective solutions. Emphasize your ability to identify problems, analyze data, and implement solutions.

- Share examples of how you have successfully resolved production issues in the past.

- Discuss your approach to problem-solving and decision-making.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your engagement and interest in the role. Prepare questions that show your understanding of the company and the industry.

- Ask about the company’s future plans and growth prospects.

- Inquire about the training and development opportunities available to employees.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a End Maker, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for End Maker positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.