Feeling lost in a sea of interview questions? Landed that dream interview for End-Touching Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common End-Touching Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

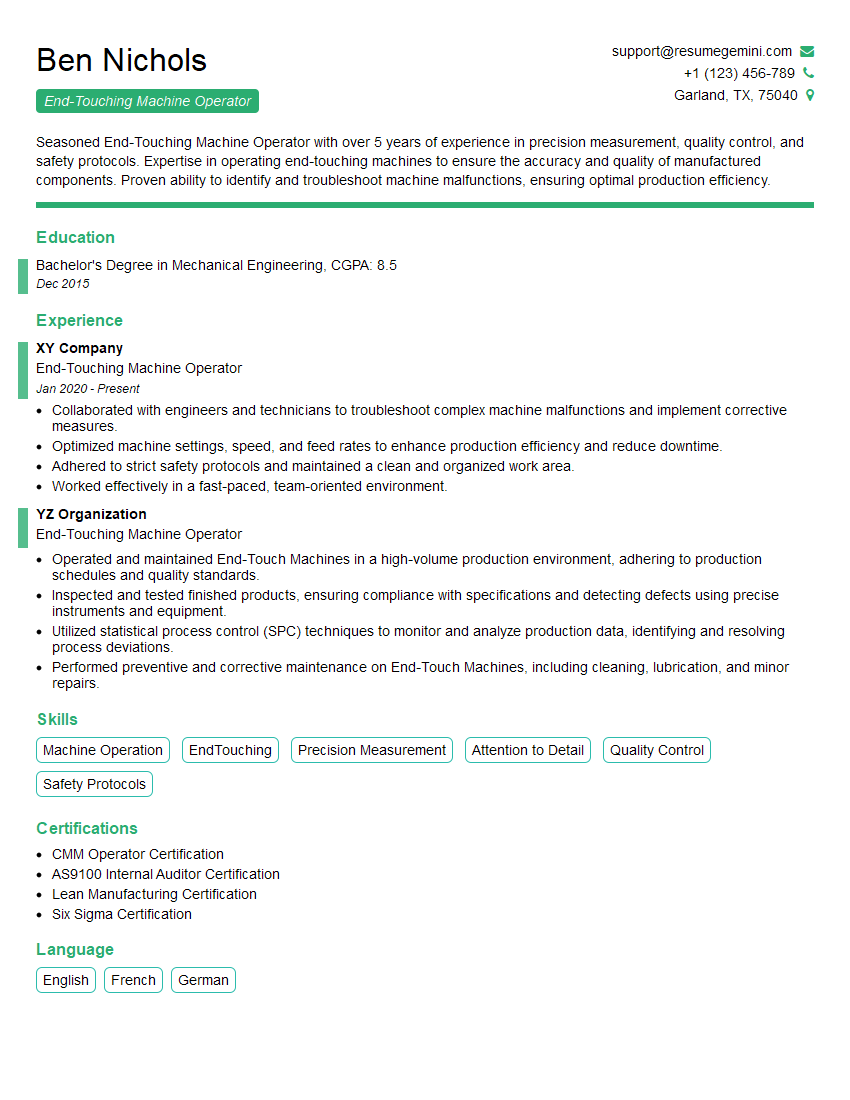

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For End-Touching Machine Operator

1. What are the key responsibilities of an End-Touching Machine Operator?

- Monitor and operate end-touching machines to accurately apply adhesive to materials.

- Inspect products for defects and ensure they meet quality standards.

- Adjust machine settings to optimize production efficiency.

- Maintain a clean and organized work area.

- Follow established safety protocols and procedures.

2. Describe the different types of end-touching machines you have operated.

- Flatbed end-touching machines

- Rotary end-touching machines

- Semi-automatic end-touching machines

- Fully-automatic end-touching machines

3. How do you ensure the accuracy of adhesive application?

- Use precision tools for precise adhesive dispensing.

- Regularly calibrate the machine to maintain accuracy.

- Inspect products frequently for any deviations from specifications.

- Adhere to established operating procedures and guidelines.

4. What are the common defects you encounter in end-touching operations?

- Uneven or excessive adhesive application

- Misalignment of adhesives

- Adhesive spills or contamination

- Product damage due to improper handling or machine malfunction

5. How do you troubleshoot common machine problems?

- Identify the cause of the problem through observation and analysis.

- Consult technical manuals or consult with experienced operators.

- Perform basic maintenance and repairs as necessary.

- Report complex issues to supervisors or maintenance personnel.

6. How do you prioritize tasks and manage your time effectively?

- Set priorities based on urgency and importance.

- Create a work schedule and stick to it.

- Delegate tasks to others when necessary.

- Minimize distractions and interruptions.

7. Describe your experience in working with different types of adhesives.

- Hot melt adhesives

- Pressure-sensitive adhesives

- Water-based adhesives

- Solvent-based adhesives

- UV-curable adhesives

8. How do you ensure the safety of yourself and others while operating end-touching machines?

- Wear appropriate personal protective equipment (PPE).

- Follow established safety protocols and procedures.

- Inspect machines regularly for any potential hazards.

- Maintain a clean and organized work area.

- Report any safety concerns to supervisors immediately.

9. What are your career goals and aspirations?

Answer will vary based on the candidate’s individual goals and aspirations.

10. Why are you interested in working for our company?

Answer will vary based on the candidate’s knowledge and interest in the company.

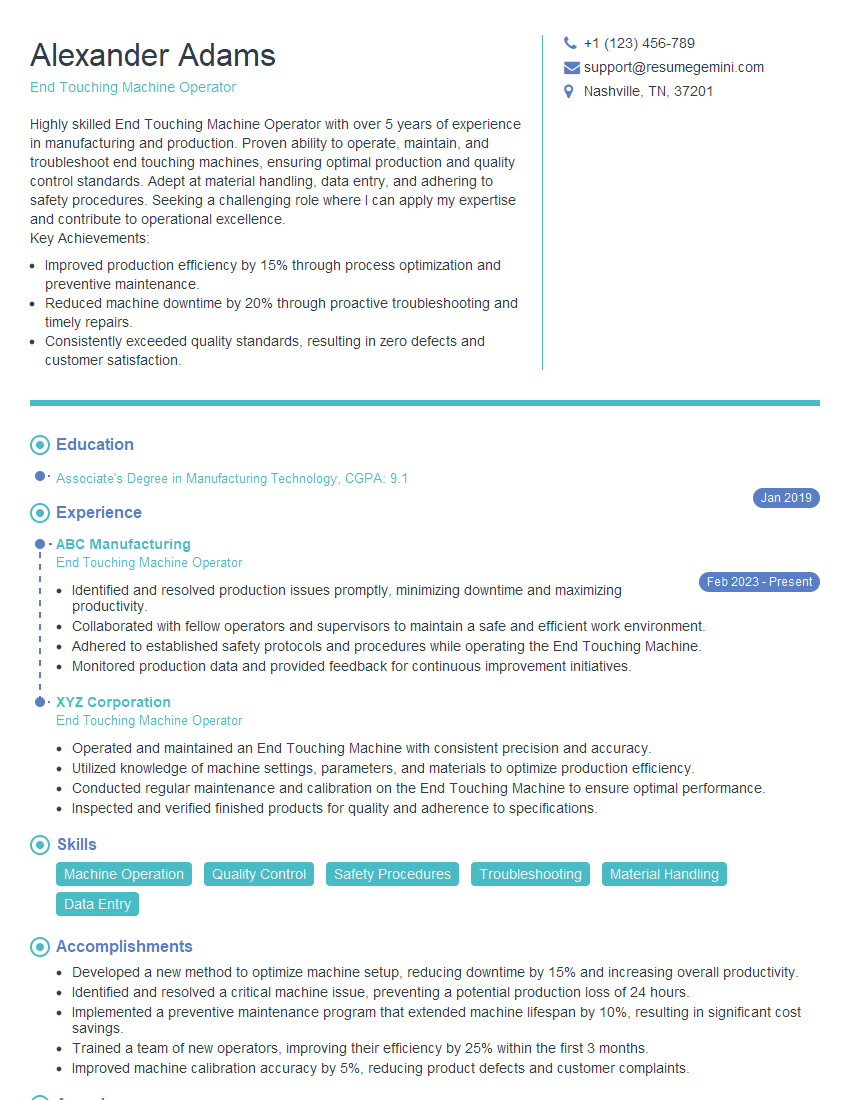

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for End-Touching Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the End-Touching Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

End-Touching Machine Operators are responsible for the proper operation and maintenance of end-touching machines, which are used to finish the edges of fabric, leather, and other materials.

1. Operate the Machine

The operator’s primary responsibility is to operate the end-touching machine efficiently and safely. This involves:

- Loading and unloading the fabric or material onto the machine

- Adjusting the machine settings according to the fabric type and desired finish

- Monitoring the machine during operation to ensure that it is running smoothly

2. Maintain the Machine

In addition to operating the machine, the operator is also responsible for its maintenance. This includes:

- Cleaning and lubricating the machine regularly

- Inspecting the machine for any signs of wear or damage

- Making minor repairs and adjustments as needed

3. Quality Control

The operator is responsible for ensuring that the finished product meets the required quality standards. This involves:

- Inspecting the finished product for any defects

- Making adjustments to the machine or the process as needed to improve quality

- Reporting any quality issues to the supervisor

4. Safety

The operator is responsible for following all safety regulations and procedures. This includes:

- Wearing the proper personal protective equipment (PPE)

- Keeping the work area clean and organized

- Reporting any safety hazards to the supervisor

Interview Tips

Preparing for an interview for an End-Touching Machine Operator position can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and the Position

Before the interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a candidate.

- Visit the company’s website to learn about their history, products or services, and mission statement.

- Read industry news and articles to stay up-to-date on the latest trends and technologies.

- Practice answering common interview questions, such as “Why are you interested in this position?” and “What are your strengths and weaknesses?”.

2. Prepare for Technical Questions

During the interview, you can expect to be asked technical questions about end-touching machines. Be prepared to discuss your experience with different types of machines, as well as your knowledge of machine maintenance and troubleshooting.

- Review the job description and identify the key skills and qualifications required.

- Think about your past experiences that demonstrate your skills and abilities.

- Prepare examples of times when you have successfully operated and maintained end-touching machines.

3. Be Enthusiastic and Professional

First impressions matter. When you arrive for the interview, be sure to dress professionally and arrive on time. During the interview, be enthusiastic and positive about the position and the company.

- Make eye contact with the interviewer and speak clearly and confidently.

- Be polite and respectful, even if you don’t get the job.

- Follow up with the interviewer after the interview to thank them for their time.

4. Ask Questions

Asking questions at the end of the interview shows that you are interested and engaged. It also gives you an opportunity to learn more about the company and the position.

- Ask about the company’s culture and values.

- Inquire about the company’s training and development opportunities.

- Ask about the company’s growth plans and how you can contribute to their success.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the End-Touching Machine Operator role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.