Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the End Worker interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a End Worker so you can tailor your answers to impress potential employers.

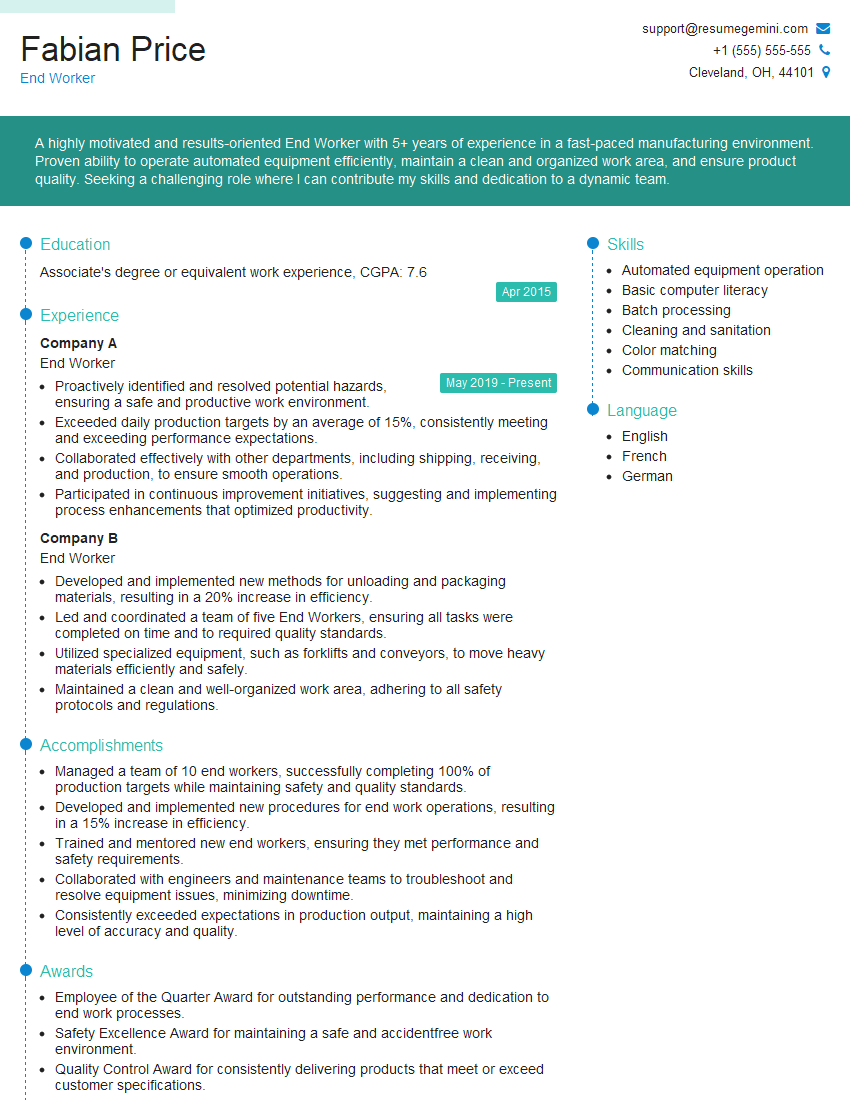

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For End Worker

1. Explain the responsibilities of an End Worker in a manufacturing environment?

As an End Worker in a manufacturing environment, I play a crucial role in ensuring the smooth operation and efficiency of the production line. My responsibilities include:

- Operate and maintain equipment to produce high-quality products.

- Monitor production processes to identify and address any potential issues.

- Package and ship finished products according to specifications.

- Maintain a clean and organized work area to promote safety and productivity.

- Collaborate with team members to ensure seamless workflow and meet production targets.

2. Describe the different types of equipment you have experience operating?

Manual Equipment

- Assembly tools (e.g., screwdrivers, wrenches, pliers)

- Material handling equipment (e.g., forklifts, pallet jacks)

- Inspection gauges and tools

Automated Equipment

- Computerized Numerical Control (CNC) machines

- Automated assembly lines

- Robotics

3. What process improvement techniques are you familiar with, and how have you implemented them in previous roles?

I am familiar with a range of process improvement techniques, including:

- Six Sigma: Used data analysis and statistical methods to identify and eliminate defects.

- Lean Manufacturing: Streamlined processes to reduce waste and improve efficiency.

- Kaizen: Implemented small, continuous improvements to enhance productivity.

- 5S: Organized and standardized work areas to promote efficiency.

In previous roles, I have successfully implemented these techniques to:

- Reduce downtime by 15% through improved equipment maintenance practices.

- Increase production output by 10% by optimizing production processes.

- Eliminate defects by 5% through enhanced quality control measures.

4. How do you prioritize tasks and manage your time effectively, especially under pressure?

I prioritize tasks based on their importance and urgency. I use a to-do list or project management software to track my progress and stay organized. When under pressure, I remain calm and focused, breaking down large tasks into smaller, manageable steps. I also delegate responsibilities to team members when necessary to ensure timely completion of all tasks.

5. Describe a situation where you successfully resolved a production problem or issue?

During a recent production shift, a machine malfunction resulted in a temporary halt in production. I quickly assessed the situation, identified the root cause of the issue, and implemented a temporary workaround to keep the production line running. I then reported the issue to the maintenance team and worked with them to find a permanent solution. As a result, the production downtime was minimized, and the problem was resolved efficiently.

6. How do you ensure the quality of your work, and what quality control measures do you typically follow?

I follow strict quality control measures to ensure the quality of my work. These measures include:

- Regular equipment calibration and maintenance to minimize errors.

- Inspection of raw materials and finished products to identify any defects.

- Adherence to established production standards and specifications.

- Collaboration with quality control personnel to ensure compliance with industry regulations.

7. What are your strengths and weaknesses as an End Worker?

Strengths:

- Strong attention to detail and quality.

- Ability to work independently and as part of a team.

- Proficient in operating and maintaining equipment.

- Excellent problem-solving and analytical skills.

Weaknesses:

- Can be impatient when working under tight deadlines.

- Not yet proficient in all aspects of lean manufacturing.

8. Why are you interested in working as an End Worker in our company?

I am eager to join your company as an End Worker because I am impressed by your commitment to quality and innovation. I believe that my skills and experience would be a valuable asset to your team, and I am confident that I can make a significant contribution to your organization’s success.

9. What are your salary expectations?

My salary expectations are in line with the industry average for End Workers with my level of experience and qualifications. I am willing to negotiate a competitive salary package that is commensurate with my value to your company.

10. Do you have any questions for me?

I have a few questions to gain a better understanding of the role and your company:

- Can you provide more details about the specific responsibilities and projects that I would be working on?

- What are the company’s current production targets and how do you measure success in this role?

- What opportunities are there for professional development and career growth within the company?

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for End Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the End Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

End Workers are responsible for completing a variety of tasks in a production or assembly line setting. Their duties may include:

1. Assembling products

End Workers typically work on a specific station, where they assemble products according to predetermined instructions. They use a variety of tools and equipment to complete their tasks, such as screwdrivers, wrenches, and power tools.

2. Inspecting products

End Workers are responsible for inspecting products to ensure that they meet quality standards. They look for defects, such as scratches, dents, or missing parts, and then report any problems to their supervisor.

3. Packing products

End Workers pack finished products into boxes or other containers, and prepare them for shipment.

4. Operating machinery

End Workers may operate a variety of machinery, such as conveyor belts, packaging machines, or stamping machines. They must be able to follow operating procedures and troubleshoot any problems.

Interview Tips

Preparing for an End Worker interview is important to showcase your skills and experience. Here are a few tips to help you ace the interview:

1. Research the company and position

Take the time to learn about the company you are interviewing with and the specific End Worker position. This will help you answer questions about the company and its culture, as well as demonstrate your interest in the job.

2. Practice your answers to common interview questions

There are a number of common interview questions that you may be asked, such as “Tell me about yourself” or “Why are you interested in this position?”. It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to discuss your skills and experience

The interviewer will want to know about your skills and experience as an End Worker. Be prepared to discuss your experience with assembling products, inspecting products, packing products, operating machinery, and troubleshooting problems.

4. Emphasize your teamwork and communication skills

End Workers often work as part of a team, so it is important to emphasize your teamwork and communication skills. Be prepared to discuss how you work with others to achieve common goals.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the End Worker interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!