Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Engine Maintenance Mechanic position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

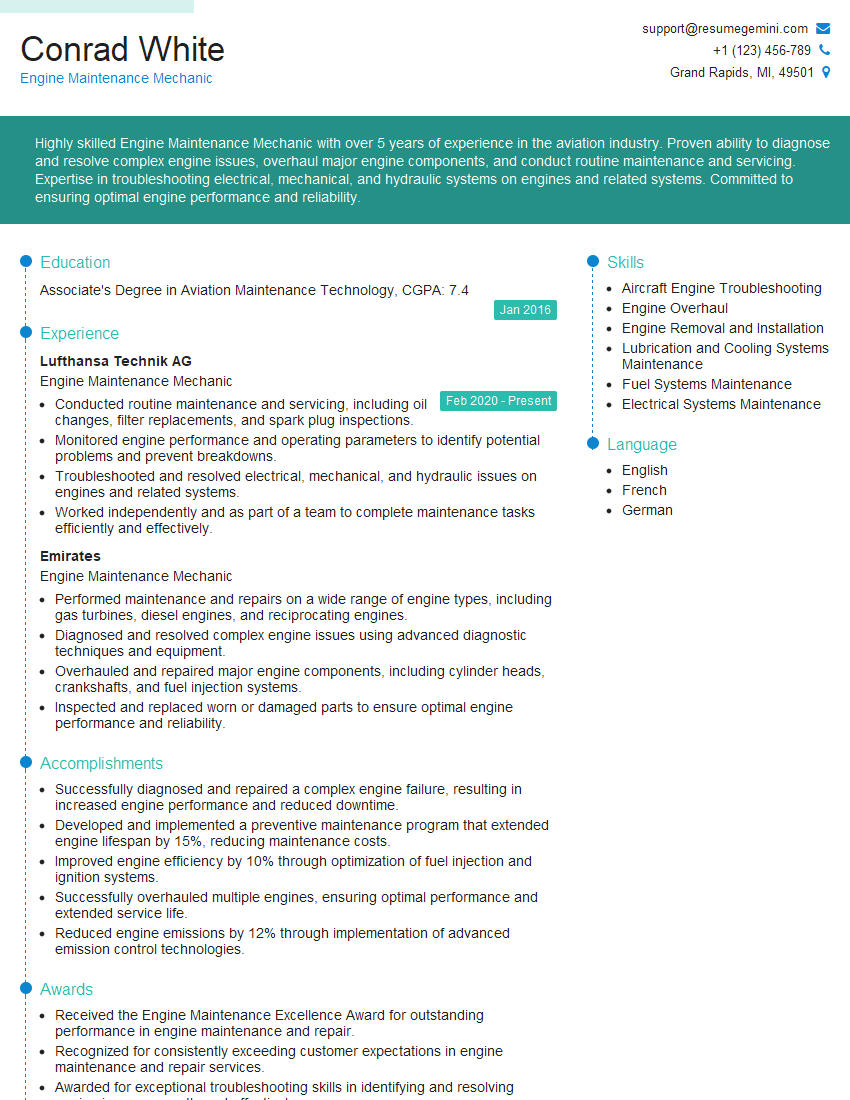

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Engine Maintenance Mechanic

1. How do you troubleshoot a diesel engine that is not starting?

- Check the battery voltage and connections.

- Inspect the fuel system for leaks or blockages.

- Verify that the air intake system is clear and unobstructed.

- Examine the electrical system for any loose or damaged wires or connections.

- Perform a compression test to assess the condition of the engine’s cylinders and valves.

2. Describe the steps involved in replacing a turbocharger.

Cooling the Engine

- Allow the engine to cool down before starting any work.

- Disconnect the battery to prevent any electrical hazards.

Removing the Old Turbocharger

- Disconnect the oil and coolant lines from the turbocharger.

- Unbolt the turbocharger from the exhaust manifold and engine block.

- Lift the turbocharger out of the vehicle.

Installing the New Turbocharger

- Insert the new turbocharger into the vehicle.

- Bolt the turbocharger to the exhaust manifold and engine block.

- Reconnect the oil and coolant lines to the turbocharger.

- Reconnect the battery.

3. How do you adjust the timing on a gasoline engine?

- Locate the timing marks on the crankshaft and camshaft.

- Use a timing light to verify the timing.

- Adjust the timing by rotating the distributor or camshaft as necessary.

- Tighten the distributor or camshaft bolts to secure the new timing setting.

4. What is the difference between a wet and dry sump lubrication system?

- Wet sump lubrication system: Oil is stored in an oil pan beneath the engine and is circulated through the engine by an oil pump.

- Dry sump lubrication system: Oil is stored in a separate reservoir and is circulated through the engine by two oil pumps.

5. How do you diagnose a faulty fuel injector?

- Inspect the fuel injector for any physical damage or leaks.

- Use a fuel injector tester to check the injector’s resistance, voltage, and flow rate.

- Listen for any unusual noises or vibrations coming from the injector.

- Compare the injector’s performance to the manufacturer’s specifications.

6. What are the symptoms of a worn-out piston ring?

- Excessive oil consumption

- Blue or black smoke from the exhaust

- Loss of compression

- Knocking or rattling noises from the engine

7. How do you test the compression in an engine?

- Remove all spark plugs.

- Insert a compression gauge into each cylinder.

- Crank the engine over several times to build up pressure.

- Record the highest pressure reading for each cylinder.

- Compare the readings to the manufacturer’s specifications.

8. What are the steps involved in overhauling a diesel engine?

- Disassembling the engine

- Inspecting and cleaning all components

- Rebuilding or replacing worn or damaged parts

- Reassembling the engine

- Testing the engine to ensure proper operation

9. What are the safety precautions to take when working on an engine?

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Disconnect the battery before starting any work.

- Allow the engine to cool down before touching it.

- Use proper tools and techniques to avoid injuries.

- Follow all manufacturer’s instructions and safety guidelines.

10. What are the latest advancements in engine maintenance technology?

- Engine diagnostics: Computerized diagnostic systems can identify and diagnose engine problems quickly and accurately.

- Engine monitoring: Sensors and data loggers can track engine performance and identify potential problems before they become major issues.

- Predictive maintenance: Algorithms and data analysis can predict when engine components are likely to fail, allowing for proactive maintenance.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Engine Maintenance Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Engine Maintenance Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Engine Maintenance Mechanics are responsible for the maintenance and repair of engines in a variety of industries, including automotive, aviation, and manufacturing. They work to ensure that engines are operating safely and efficiently, and they may specialize in specific types of engines, such as diesel or gasoline engines.

1. Diagnosing and repairing engine problems

When an engine is not running properly, Engine Maintenance Mechanics must be able to diagnose the problem and determine the best course of action to fix it. They may use a variety of tools and equipment to diagnose problems, such as multimeters, oscilloscopes, and engine analyzers. Once the problem has been diagnosed, the mechanic must then repair the engine, which may involve replacing parts, adjusting settings, or performing other repairs.

2. Performing routine maintenance

In addition to diagnosing and repairing problems, Engine Maintenance Mechanics also perform routine maintenance on engines. This may include changing oil and filters, checking spark plugs and wires, and adjusting belts and hoses. Regular maintenance helps to keep engines running smoothly and efficiently, and it can also help to prevent more serious problems from developing.

3. Overhauling engines

In some cases, an engine may be so damaged that it needs to be overhauled. This is a major repair that involves disassembling the engine and replacing or rebuilding damaged parts. Overhauling an engine is a complex and time-consuming process, but it can be necessary to restore an engine to good working condition.

4. Working with customers

Engine Maintenance Mechanics often work directly with customers to discuss their needs and to provide them with updates on the progress of their repairs. They must be able to communicate effectively with customers and to answer their questions in a clear and understandable way.

Interview Tips

Preparing for an interview for an Engine Maintenance Mechanic position can be daunting, but there are a few things you can do to increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before you go to your interview, take some time to research the company and the specific position you are applying for. This will help you to understand the company’s culture and values, as well as the specific requirements of the job. You can find information about the company on their website, social media pages, and in industry publications.

2. Practice your answers to common interview questions

There are a few common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” It is helpful to practice your answers to these questions ahead of time so that you can deliver them confidently and clearly.

3. Be prepared to talk about your experience and qualifications

The interviewer will want to know about your experience and qualifications as an Engine Maintenance Mechanic. Be prepared to discuss your skills in diagnosing and repairing engines, performing routine maintenance, and overhauling engines. You should also be able to provide examples of your work experience that demonstrate your abilities.

4. Dress professionally and arrive on time

First impressions matter, so make sure you dress professionally for your interview. You should also arrive on time for your interview, as this shows that you are respectful of the interviewer’s time.

Next Step:

Now that you’re armed with the knowledge of Engine Maintenance Mechanic interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Engine Maintenance Mechanic positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini