Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Engine Repairer, Production position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

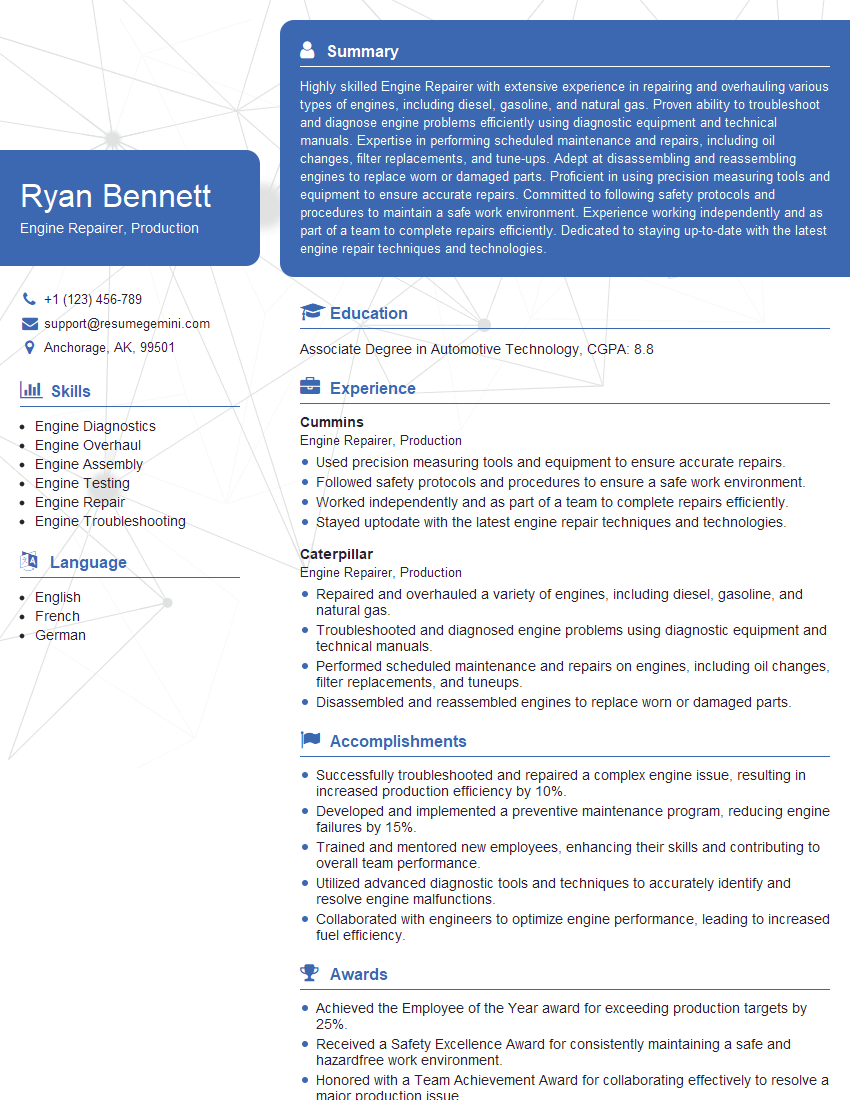

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Engine Repairer, Production

1. Explain the steps involved in troubleshooting a diesel engine that is experiencing a loss of power?

Troubleshooting Steps to Address Diesel Engine Power Loss:

- Verify fuel supply: Check fuel level, inspect fuel lines for blockages, and test fuel pump to ensure proper fuel delivery.

- Inspect air intake system: Examine air filter for clogging, check for leaks in air intake hoses and turbocharger (if applicable).

- Check compression: Measure cylinder compression to identify any potential mechanical issues such as worn piston rings or valves.

- Examine turbocharger (if applicable): Inspect turbocharger for damage or excessive wear, test boost pressure to ensure proper functioning.

- Diagnose electrical system: Check battery health, starter motor operation, and electrical connections to ensure proper power supply.

- Examine fuel injection system: Test fuel injectors for proper operation, check fuel rail pressure to identify any issues with fuel delivery.

2. Describe the different types of engine coolants and their applications

Coolant Types and Applications:

- Inorganic Coolant (Green): Traditional coolant with silicates and phosphates, suitable for older vehicles and engines without aluminum components.

- Organic Acid Technology (OAT) Coolant (Orange/Red): Long-lasting coolant with organic acid inhibitors, recommended for aluminum engines and modern vehicles.

- Hybrid Organic Acid Technology (HOAT) Coolant (Pink/Purple): Extended-life coolant with a blend of inorganic and organic inhibitors, suitable for high-performance engines.

- Universal Coolant: Compatible with all types of coolant systems, but may not provide optimal protection for specific engine materials.

3. How do you diagnose and repair a blown head gasket?

Diagnosis and Repair of a Blown Head Gasket:

- Symptom Check: Look for signs of coolant leaks, overheating, white smoke from exhaust, or rough engine operation.

- Pressure Test: Perform a cylinder leak-down test or a radiator pressure test to identify any leaks in the head gasket.

- Visual Inspection: Remove the cylinder head and inspect the head gasket for damage or failure.

- Repair Process: Replace the damaged head gasket, clean the mating surfaces, and properly torque the cylinder head bolts to manufacturer specifications.

4. Explain the working principle of a turbocharger

Working Principle of a Turbocharger:

- Exhaust Gas Flow: Exhaust gases from the engine enter the turbocharger’s turbine.

- Turbine Rotation: The exhaust gases spin the turbine, which is connected to a compressor wheel.

- Air Compression: The compressor wheel draws in air and compresses it.

- Increased Air Density: The compressed air is then forced into the engine’s intake manifold, increasing the air density and oxygen content.

- Power Enhancement: The increased air mass and oxygen content allow for more efficient combustion and increased engine power output.

5. How do you identify and resolve a misfire in a gasoline engine?

Troubleshooting a Gasoline Engine Misfire:

- Symptom Check: Listen for irregular engine operation, feel for vibrations, or observe check engine light illumination.

- Code Retrieval: Use an OBD-II scanner to retrieve any diagnostic trouble codes related to misfiring.

- Component Inspection: Check spark plugs for damage or wear, test ignition coils for proper function, and examine fuel injectors for clogging or malfunction.

- Electrical Diagnostics: Inspect wiring and electrical connections for any breaks or shorts that could affect spark delivery.

- Mechanical Issues: Examine valve timing, compression, and cylinder head for any potential mechanical problems causing misfires.

6. Describe the purpose and operation of an EGR (Exhaust Gas Recirculation) system

Purpose and Operation of an EGR System:

- Emissions Reduction: EGR systems reduce NOx emissions by recirculating a portion of exhaust gases back into the intake manifold.

- Exhaust Cooling: The recirculated exhaust gases lower the combustion temperature, reducing the formation of NOx.

- Valve Control: An EGR valve regulates the flow of exhaust gases based on engine load and operating conditions.

- Control Strategies: Modern EGR systems use electronic controls and sensors to optimize exhaust gas recirculation rates for improved performance and emissions reduction.

7. How do you perform a compression test on a diesel engine?

Compression Test Procedure for Diesel Engines:

- Engine Preparation: Ensure the engine is warm and the battery is fully charged.

- Equipment Setup: Connect a compression gauge to the cylinder to be tested.

- Crank Engine: Crank the engine with the glow plug system disabled (if applicable).

- Peak Pressure Measurement: Record the highest pressure reading displayed on the compression gauge.

- Cylinder Comparison: Repeat the test on other cylinders to compare compression pressure and identify any potential problems.

8. Describe the different types of fuel injection systems used in modern diesel engines?

Types of Fuel Injection Systems in Diesel Engines:

- Mechanical Fuel Injection: Utilizes a high-pressure fuel pump, injectors, and a mechanical governor to control fuel delivery.

- Electronic Fuel Injection (EFI): Employs electronic sensors and a computer to manage fuel injection timing, duration, and pressure.

- Common Rail Fuel Injection: Stores fuel in a common rail at high pressure and uses electronically controlled injectors to deliver precise fuel amounts.

- Piezoelectric Fuel Injection: Employs piezoelectric injectors that use electrical pulses to control fuel flow with high precision and speed.

9. How do you troubleshoot a charging system problem on a gasoline engine?

Troubleshooting Charging System Issues in Gasoline Engines:

- Voltage Check: Check battery voltage with a multimeter while the engine is running.

- Alternator Output Test: Disconnect the battery and test alternator output voltage at the alternator terminals.

- Stator and Rotor Inspection: Inspect the alternator’s stator and rotor for any visible damage or wear.

- Voltage Regulator Examination: Test the voltage regulator to ensure it is properly controlling alternator output.

- Wiring and Connection Checks: Examine wiring and connections for any breaks, shorts, or loose terminals.

10. Describe the importance of using proper engine oil and the consequences of using the wrong type or grade?

Importance of Proper Engine Oil and Consequences of Wrong Selection:

- Lubrication: Proper engine oil provides lubrication to moving parts, reducing friction and wear.

- Cooling: Oil absorbs heat from engine components and helps maintain optimal operating temperatures.

- Protection: Oil forms a protective film on engine surfaces, preventing corrosion and sludge buildup.

- Consequences of Wrong Oil: Using the wrong oil viscosity or type can lead to insufficient lubrication, overheating, increased wear, and engine damage.

- Warranty Implications: Using non-approved or incorrect oil can void engine warranties.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Engine Repairer, Production.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Engine Repairer, Production‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Engine Repairer, Production will be responsible for carrying out repairs and maintenance on engines used in production environments, ensuring that they operate efficiently and meet safety standards. Key responsibilities include:

1. Inspecting and Diagnosing Engines

Inspecting engines to identify any issues or areas requiring repair. Performing diagnostic tests to determine the root cause of problems and developing repair plans.

2. Repairing and Overhauling Engines

Disassembling engines to access damaged components. Replacing or repairing worn or defective parts. Overhauling engines by replacing major components and rebuilding them to original specifications.

3. Engine Assembly and Tuning

Assembling engines following established procedures. Adjusting and tuning engines to optimize performance and meet operating specifications.

4. Maintenance and Troubleshooting

Performing routine maintenance tasks such as oil changes and filter replacements. Troubleshooting engine malfunctions and resolving issues promptly.

5. Compliance and Safety

Ensuring that all repairs and maintenance activities comply with safety regulations and industry standards. Maintaining a clean and organized work area to prevent accidents.

Interview Tips

Preparing for an interview can be daunting, but with the right tips and strategies, you can increase your chances of success. Here are some valuable interview preparation tips for the position of Engine Repairer, Production:

1. Research the Company and the Role

Before the interview, take the time to learn about the company, its industry, and the specific role you are applying for. This will demonstrate your interest in the position and help you tailor your answers to the interviewer’s questions.

2. Practice Answering Common Interview Questions

There are several common interview questions that you are likely to encounter. Practice answering these questions out loud to improve your delivery and confidence. Consider using the STAR method (Situation, Task, Action, Result) to structure your responses, providing specific examples from your experience.

3. Highlight Your Skills and Experience

Review the job description and identify the key skills and experience required for the role. Focus on highlighting your relevant skills and how they align with the company’s needs. Use concrete examples to demonstrate your proficiency in engine repair, maintenance, and troubleshooting.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. Prepare a few questions to ask the interviewer about the company’s culture, growth opportunities, or any specific aspects of the role that you are curious about.

5. Dress Professionally and Arrive on Time

Dress appropriately for the interview, typically business casual attire. Arrive on time to show your respect for the interviewer and the company. Being punctual demonstrates your professionalism and time management skills.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Engine Repairer, Production interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.