Are you gearing up for a career in Engineering Production Liaison? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Engineering Production Liaison and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

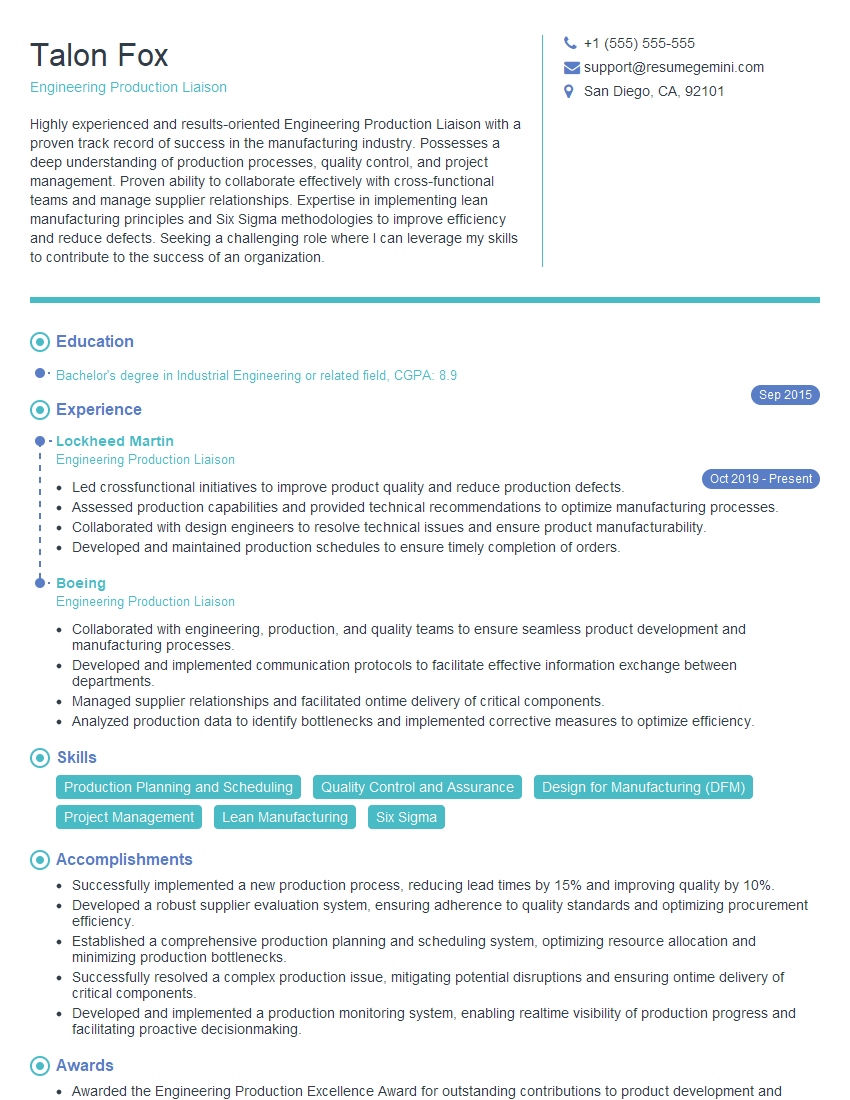

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Engineering Production Liaison

1. What are the key responsibilities of an engineering production liaison?

Responsibilities of an engineering production liaison include:

- Acting as a liaison between engineering and production departments.

- Ensuring that production plans are in line with design specifications.

- Coordinating the resolution of production issues.

- Providing technical support to production staff.

- Monitoring production processes to ensure quality standards are met.

2. How do you ensure that production plans are in line with design specifications?

Collaboration with Engineering Department

- Regularly review design specifications and drawings.

- Discuss design requirements with engineering team.

- Identify potential issues and communicate them to production.

Communication with Production Department

- Provide production team with clear instructions and documentation.

- Review production plans and ensure they align with design.

- Address any discrepancies or changes promptly.

3. What are some common challenges faced by an engineering production liaison?

Challenges commonly faced by engineering production liaisons include:

- Bridging the communication gap between engineering and production.

- Balancing the demands of both departments.

- Resolving conflicts and coordinating solutions.

- Maintaining open communication and collaboration throughout the production process.

- Staying up-to-date with technical advancements and industry trends.

4. How do you prioritize tasks and manage multiple projects simultaneously?

To prioritize tasks and manage multiple projects simultaneously, I employ the following strategies:

- Utilize project management tools and techniques.

- Collaborate with team members to allocate resources effectively.

- Set clear priorities and communicate them to stakeholders.

- Delegate tasks to team members based on their strengths and expertise.

- Monitor progress regularly and adjust priorities as needed.

5. Describe a situation where you successfully coordinated the resolution of a production issue.

In a previous role, a production issue arose due to a discrepancy between the design specifications and the production process. I facilitated a meeting between the engineering and production teams to discuss the issue and identify potential solutions. By fostering open communication and collaboration, we developed a modified production process that met the design requirements while maintaining efficiency. The issue was resolved promptly, preventing delays and ensuring customer satisfaction.

6. How do you stay informed about the latest technology and advancements in the manufacturing industry?

To stay informed about the latest technology and advancements in the manufacturing industry, I use a combination of approaches:

- Attend industry events, conferences, and webinars.

- Read technical journals and industry publications.

- Network with colleagues and industry professionals.

- Participate in online forums and discussion groups.

- Conduct research and explore new technologies through online platforms.

7. What are your strengths and how do they align with the requirements of the engineering production liaison role?

My strengths include:

- Excellent communication and interpersonal skills.

- Strong technical understanding of engineering and production processes.

- Proven ability to bridge the gap between engineering and production.

- Experience in coordinating and resolving production issues.

- Commitment to continuous learning and staying up-to-date with industry trends.

These strengths align well with the requirements of the engineering production liaison role as they enable me to effectively collaborate with both engineering and production teams, ensure the smooth flow of production, and contribute to the overall success of the organization.

8. Describe your experience in managing and resolving production defects.

In my previous role, I was responsible for managing and resolving production defects. I employed a systematic approach that involved:

- Identifying and documenting the defect.

- Conducting a root cause analysis to determine the cause of the defect.

- Developing and implementing corrective actions to prevent future occurrences.

- Monitoring the effectiveness of the corrective actions and making adjustments as necessary.

- Communicating with stakeholders to provide updates and ensure transparency.

9. How do you ensure that production processes comply with relevant standards and regulations?

To ensure that production processes comply with relevant standards and regulations, I take the following steps:

- Stay up-to-date on industry regulations and best practices.

- Review production processes regularly to identify potential non-compliance issues.

- Implement quality control measures to prevent and detect non-conformances.

- Train production staff on compliance requirements.

- Conduct internal audits to assess compliance and identify areas for improvement.

10. What are your expectations for this role and how do you plan to contribute to the team?

My expectations for this role are to:

- Foster effective communication and collaboration between engineering and production.

- Ensure that production plans are aligned with design specifications.

- Proactively identify and resolve production issues.

- Contribute to continuous improvement efforts within the organization.

- Stay abreast of industry trends and best practices.

I plan to contribute to the team by leveraging my skills and experience to:

- Strengthen the relationship between engineering and production.

- Improve production efficiency and quality.

- Reduce production costs and lead times.

- Enhance the organization’s competitiveness in the market.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Engineering Production Liaison.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Engineering Production Liaison‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Engineering Production Liaison is a multifaceted role in the manufacturing industry, bridging the gap between engineering and production departments to ensure the seamless execution of product designs. Key responsibilities include:

1. Facilitating Communication and Coordination

Acting as a communication hub, Engineering Production Liaisons facilitate the exchange of information between engineering and production teams. They interpret and convey design specifications, timelines, and quality expectations, ensuring alignment and avoiding misunderstandings.

- Attending design reviews, production meetings, and daily huddles to stay abreast of project progress and potential challenges.

- Disseminating information in timely and clear formats, utilizing various communication channels such as emails, instant messaging, and documentation.

- Addressing queries, clarifying technical details, and resolving conflicts that may arise between engineering and production teams.

2. Product Design and Development

Engineering Production Liaisons play a crucial role in the product development process, providing engineering support during design and prototyping phases.

- Working closely with engineers to understand their design concepts and feasibility for mass production.

- Analyzing production processes, identifying potential bottlenecks, and recommending design modifications to enhance manufacturability.

- Participating in testing and validation activities to ensure that products meet specifications and quality standards.

3. Production Planning and Execution

Liaisons actively participate in production planning and execution, ensuring smooth transitions from design to manufacturing.

- Developing production schedules and timelines in collaboration with production supervisors and engineering teams.

- Monitoring production progress, identifying deviations from plans, and implementing corrective actions.

- Providing technical support to manufacturing personnel, offering guidance on complex processes and troubleshooting production issues.

4. Problem-Solving and Continuous Improvement

Engineering Production Liaisons are proactive problem solvers, working to identify and address challenges throughout the production process.

- Investigating production defects and failures, analyzing root causes, and recommending solutions to prevent recurrence.

- Participating in continuous improvement initiatives, suggesting process enhancements to increase efficiency and reduce production costs.

- Staying abreast of industry trends and emerging technologies to identify opportunities for innovation and process optimization.

Interview Tips

To ace an Engineering Production Liaison interview, candidates should be well-prepared, demonstrating not only technical knowledge but also strong communication and problem-solving abilities.

1. Research the Company and Role

Thoroughly research the company and the specific role you are applying for. Understand the company’s culture, values, and product offerings.

- Visit the company website, read industry news, and consult social media platforms to gather insights.

- Review the job description carefully, highlighting key responsibilities and qualifications.

- Prepare specific examples that showcase your relevant skills and experience.

2. Highlight Technical Expertise

Demonstrate your deep understanding of engineering principles, production processes, and quality control measures.

- Emphasize your experience in design and development, highlighting your ability to interpret designs and provide practical solutions.

- Discuss your knowledge of manufacturing techniques, materials, and production equipment.

- Provide examples of how you have applied engineering principles to solve production challenges.

3. Communication and Interpersonal Skills

Exhibit excellent communication and interpersonal skills, emphasizing your ability to work effectively with diverse teams.

- Highlight your ability to convey technical information clearly and effectively to both technical and non-technical audiences.

- Demonstrate your strong listening skills and empathy, showcasing your ability to understand and respond to the needs of others.

- Provide examples of how you have successfully resolved conflicts and fostered collaboration between teams.

4. Problem-Solving and Innovation

Emphasize your problem-solving abilities and innovative approach to challenges.

- Discuss your analytical approach to identifying and resolving production issues.

- Describe how you have implemented innovative solutions to improve efficiency or reduce costs.

- Share examples of your proactive efforts to identify potential challenges and mitigate risks.

Next Step:

Now that you’re armed with the knowledge of Engineering Production Liaison interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Engineering Production Liaison positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini