Feeling lost in a sea of interview questions? Landed that dream interview for Enrobing Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Enrobing Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

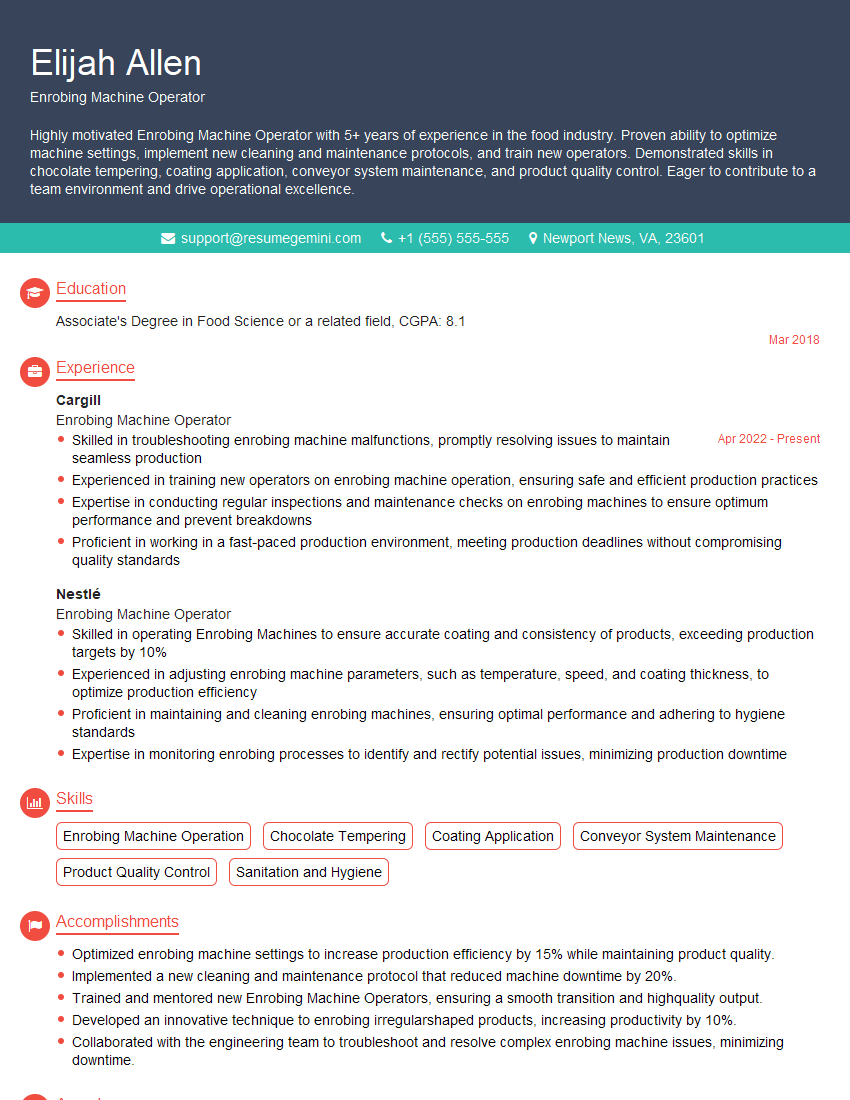

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Enrobing Machine Operator

1. Describe the key responsibilities and tasks of an Enrobing Machine Operator?

As an Enrobing Machine Operator, my primary responsibilities involve operating and maintaining enrobing machines, ensuring the smooth and efficient production of enrobed products. Key tasks include:

- Setting up and operating enrobing machines according to product specifications

- Monitoring the enrobing process, ensuring the correct application and thickness of coating

- Maintaining a clean and sanitary work area in compliance with food safety regulations

- Troubleshooting and resolving operational issues with the enrobing machine

- Performing routine maintenance and cleaning of the machine to ensure optimal performance

2. Explain the different types of enrobing machines and their applications?

Batch enrobing machines

Batch enrobing machines are used for small to medium-scale production. They consist of a tank filled with melted coating, through which products are manually or automatically passed for enrobing.

Continuous enrobing machines

Continuous enrobing machines are typically used for high-volume production. They consist of a conveyor belt that transports products through a cascade of melted coating, ensuring uniform and precise coverage.

Tunnel enrobing machines

Tunnel enrobing machines are designed for large-scale production. They involve a conveyor belt passing through a tunnel-like structure, where products are subjected to a controlled environment and coating process.

3. How do you ensure product quality and consistency during the enrobing process?

- Regularly calibrating and maintaining the enrobing machine to ensure accurate temperature and coating thickness

- Monitoring product flow and adjusting machine speed to prevent over-coating or under-coating

- Visually inspecting enrobed products for defects, such as breaks, uneven coating, or contamination

- Following established quality control procedures and adhering to food safety standards

4. Describe the techniques used to troubleshoot and resolve operational issues with enrobing machines?

- Identifying the source of the problem by observing the machine’s behavior and error codes

- Consulting technical manuals and documentation to determine potential solutions

- Performing basic troubleshooting steps, such as checking sensors, belts, and electrical connections

- Escalating complex issues to supervisors or maintenance technicians for further assistance

5. What measures do you take to ensure a safe and hygienic work environment in the enrobing area?

- Wearing appropriate personal protective equipment (PPE), such as gloves, hairnets, and safety glasses

- Maintaining a clean and organized work area free of spills or debris

- Sanitizing equipment and surfaces regularly to prevent contamination

- Following established safety protocols and reporting any potential hazards or incidents

6. How do you prioritize tasks and manage multiple responsibilities effectively?

- Assessing the urgency and importance of each task

- Creating a structured work schedule and setting realistic deadlines

- Delegating tasks to colleagues or requesting assistance when necessary

- Communicating effectively with supervisors and team members to ensure coordination and avoid conflicts

7. Describe your experience in working with different types of confectionery products during the enrobing process?

During my previous experience as an Enrobing Machine Operator, I have worked with a variety of confectionery products, including:

- Chocolate-covered biscuits and cookies

- Candy bars and truffles

- Fruit and nut clusters

- Glazed pastries and donuts

For each product, I have adjusted the enrobing machine settings and techniques to achieve the desired coating consistency and appearance.

8. How do you stay up-to-date with the latest advancements in enrobing technology and best practices?

- Attending industry conferences and trade shows

- Reading technical publications and research articles

- Consulting with equipment manufacturers and suppliers

- Participating in training programs and workshops

By continuously learning and adapting to new technologies and practices, I ensure that I deliver optimal performance and maintain the highest standards in the enrobing process.

9. What is your approach to continuous improvement in the enrobing process?

- Regularly monitoring machine performance and product quality

- Identifying areas for improvement and implementing changes

- Seeking feedback from colleagues, supervisors, and quality control teams

- Participating in brainstorming sessions and sharing ideas

- Documenting best practices and lessons learned to facilitate knowledge transfer

By embracing continuous improvement, I strive to optimize the enrobing process, reduce downtime, enhance product quality, and increase operational efficiency.

10. Describe a situation where you had to troubleshoot a complex issue with an enrobing machine and how you resolved it?

In one instance, the enrobing machine was producing products with an uneven coating. After examining the machine, I noticed that the temperature of the coating had dropped slightly below the optimal range. I immediately adjusted the temperature settings and restarted the machine. This simple troubleshooting step resolved the issue, ensuring the production of high-quality enrobed products.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Enrobing Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Enrobing Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

An Enrobing Machine Operator is responsible for operating enrobing machines to evenly coat food products in chocolate or other coatings. Their primary duties involve:

1. Equipment Operation and Maintenance

Operate and maintain enrobing machines, ensuring they run smoothly and efficiently.

- Set up, calibrate, and adjust machine settings to achieve desired coating consistency and thickness.

- Monitor machine performance, identify potential issues, and perform routine maintenance tasks to prevent breakdowns.

2. Product Handling and Quality Control

Handle food products with care, ensuring they are evenly coated and free from defects.

- Inspect products before and after the enrobing process, removing any damaged or non-compliant items.

- Monitor coating thickness and quality, making adjustments as needed to meet specifications.

- Maintain a clean and organized work area to ensure product safety and hygiene.

3. Production Efficiency and Output

Ensure high production rates while maintaining quality standards.

- Plan and prioritize production schedules to maximize efficiency and meet customer demands.

- Troubleshoot and resolve production issues, minimizing downtime and optimizing output.

- Collaborate with team members to ensure smooth production flow and effective coordination.

4. Training and Supervision

May provide training and supervision to new or junior operators.

- Train operators on safe and efficient machine operation, product handling, and quality control procedures.

- Supervise operators, ensuring they follow established protocols and maintain high standards of performance.

Interview Tips

To ace an interview for an Enrobing Machine Operator position, consider the following tips:

1. Research the Company and Role

Before the interview, thoroughly research the company and the specific role. This will demonstrate your interest and preparedness.

- Visit the company website to learn about their history, products/services, and company culture.

- Read online reviews and articles to gain insights into employee experiences and the company’s reputation.

2. Highlight Relevant Skills and Experience

Tailor your resume and cover letter to emphasize your relevant skills and experience. Quantify your accomplishments whenever possible.

- Showcase your proficiency in operating enrobing machines and your knowledge of coating techniques.

- Provide specific examples of how you have ensured product quality and maintained high production rates.

- Highlight any experience in training or supervising other operators.

3. Prepare for Common Interview Questions

Be prepared to answer common interview questions related to the role and your qualifications. Practice your answers to ensure you are clear and concise.

- Tell me about your experience operating enrobing machines.

- How do you ensure product quality and consistency during the enrobing process?

- Describe a time when you faced a challenge while operating the enrobing machine. How did you handle it?

4. Ask Informed Questions

At the end of the interview, ask thoughtful questions that show your interest in the company and the role. This demonstrates your engagement and enthusiasm.

- What are the key performance indicators (KPIs) for this role?

- What opportunities are there for professional development and career growth within the company?

- Can you provide more details about the company’s quality control processes?

Next Step:

Now that you’re armed with the knowledge of Enrobing Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Enrobing Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini