Feeling lost in a sea of interview questions? Landed that dream interview for Epitaxial Reactor Technician but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Epitaxial Reactor Technician interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

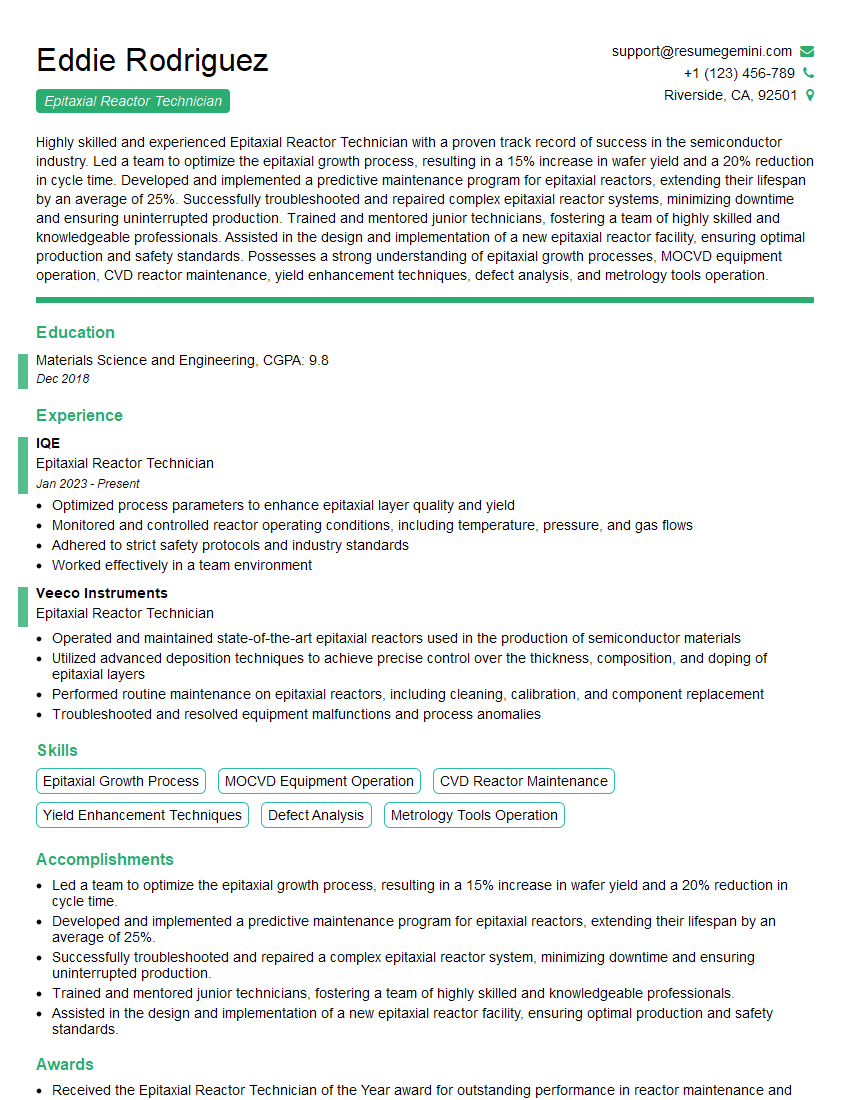

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Epitaxial Reactor Technician

1. Describe the key steps involved in the epitaxial growth process?

The epitaxial growth process involves the following key steps:

- Substrate preparation: The substrate is cleaned and prepared to remove any contaminants or defects.

- Buffer layer deposition: A thin buffer layer is deposited on the substrate to improve the quality of the epitaxial layer.

- Epitaxial layer growth: The epitaxial layer is grown on the buffer layer using a variety of techniques, such as molecular beam epitaxy (MBE) or chemical vapor deposition (CVD).

- Post-growth processing: The epitaxial layer is subjected to post-growth processing steps, such as annealing or etching, to improve its properties.

2. What are the different types of epitaxial reactors?

The different types of epitaxial reactors include:

- Molecular beam epitaxy (MBE) reactors: MBE reactors use a molecular beam to deposit the epitaxial layer.

- Chemical vapor deposition (CVD) reactors: CVD reactors use a chemical vapor to deposit the epitaxial layer.

- Liquid phase epitaxy (LPE) reactors: LPE reactors use a liquid phase to deposit the epitaxial layer.

3. What are the key parameters that need to be controlled during epitaxial growth?

The key parameters that need to be controlled during epitaxial growth include:

- Temperature: The temperature of the substrate and the growth chamber must be carefully controlled to ensure the proper growth of the epitaxial layer.

- Pressure: The pressure in the growth chamber must be controlled to ensure the proper deposition of the epitaxial layer.

- Gas flow rates: The flow rates of the gases used in the epitaxial growth process must be carefully controlled to ensure the proper deposition of the epitaxial layer.

4. What are the common defects that can occur during epitaxial growth?

The common defects that can occur during epitaxial growth include:

- Stacking faults: Stacking faults are defects that occur when the atoms in the epitaxial layer are not arranged in the correct order.

- Dislocations: Dislocations are defects that occur when there is a break in the crystal structure of the epitaxial layer.

- Inclusions: Inclusions are defects that occur when foreign atoms or particles are incorporated into the epitaxial layer.

5. How do you troubleshoot epitaxial growth problems?

To troubleshoot epitaxial growth problems, you can use the following steps:

- Identify the problem: The first step is to identify the problem by examining the epitaxial layer using a variety of techniques, such as optical microscopy or X-ray diffraction.

- Determine the cause of the problem: Once the problem has been identified, you can determine the cause of the problem by examining the epitaxial growth process and the materials used.

- Develop a solution: Once the cause of the problem has been determined, you can develop a solution to fix the problem.

6. What are the safety precautions that need to be taken when working with epitaxial reactors?

The safety precautions that need to be taken when working with epitaxial reactors include:

- Wear appropriate personal protective equipment (PPE): PPE includes gloves, safety glasses, and a lab coat.

- Be aware of the hazards of the gases used in the epitaxial growth process: The gases used in the epitaxial growth process can be hazardous, so it is important to be aware of their hazards and to take appropriate precautions.

- Follow the manufacturer’s instructions for the epitaxial reactor: The manufacturer’s instructions will provide specific safety precautions for the epitaxial reactor.

7. What are the different applications of epitaxial growth?

Epitaxial growth is used in a variety of applications, including:

- Semiconductor devices: Epitaxial growth is used to grow the semiconductor layers in semiconductor devices, such as transistors and diodes.

- Optical devices: Epitaxial growth is used to grow the optical layers in optical devices, such as lasers and LEDs.

- Magnetic devices: Epitaxial growth is used to grow the magnetic layers in magnetic devices, such as hard drives and magnetic sensors.

8. What is the future of epitaxial growth?

The future of epitaxial growth is bright. Epitaxial growth is a key technology for the development of new and innovative semiconductor devices, optical devices, and magnetic devices.

9. What are the challenges in epitaxial growth?

The challenges in epitaxial growth include:

- Controlling the growth process: The epitaxial growth process is a complex process that must be carefully controlled to ensure the proper growth of the epitaxial layer.

- Achieving high yields: The yield of epitaxial wafers can be low, so it is important to develop techniques to improve the yield.

- Reducing the cost of epitaxial growth: The cost of epitaxial growth can be high, so it is important to develop techniques to reduce the cost.

10. What are the latest developments in epitaxial growth?

The latest developments in epitaxial growth include:

- The development of new epitaxial growth techniques: New epitaxial growth techniques are being developed to improve the quality and yield of epitaxial wafers.

- The use of new materials in epitaxial growth: New materials are being used in epitaxial growth to develop new and innovative semiconductor devices, optical devices, and magnetic devices.

- The integration of epitaxial growth with other semiconductor processing techniques: Epitaxial growth is being integrated with other semiconductor processing techniques to develop new and innovative semiconductor devices.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Epitaxial Reactor Technician.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Epitaxial Reactor Technician‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Epitaxial Reactor Technicians play a vital role in the semiconductor industry, performing critical tasks related to epitaxial reactor operations, maintenance, and process development. Key job responsibilities include:Epitaxial Reactor Operation:

1. Reactor Operation and Monitoring

Responsible for operating and monitoring epitaxial reactors to produce high-quality semiconductor wafers.

- Controlling reactor parameters (e.g., temperature, pressure, gas flows) to optimize epitaxial growth.

- Monitoring process metrics (e.g., film thickness, uniformity, crystal quality) to ensure wafer quality.

2. Troubleshooting and Maintenance

Troubleshooting and resolving equipment malfunctions and process issues to minimize downtime.

- Diagnosing and repairing mechanical, electrical, and software problems in epitaxial reactors.

- Performing preventive maintenance procedures (e.g., cleaning, calibration) to ensure optimal reactor performance.

3. Process Development and Improvement

Participate in process development and improvement efforts to enhance epitaxial reactor capabilities and wafer quality.

- Evaluating new deposition techniques and materials to improve epitaxial film properties.

- Optimizing process parameters to increase yield and reduce defects in semiconductor wafers.

4. Quality Control and Documentation

Ensuring the quality of epitaxial wafers and maintaining detailed records of reactor operations and maintenance.

- Performing wafer inspections and measurements to verify compliance with specifications.

- Maintaining accurate records of reactor parameters, maintenance procedures, and process data for traceability and audit purposes.

Interview Tips

To prepare effectively for an Epitaxial Reactor Technician interview, consider the following tips:1. Research the Company and Industry

Learn about the company’s history, products, and market position. Stay updated on the latest trends and advancements in the semiconductor industry.

- Visit the company’s website and social media pages.

- Read industry publications and articles.

2. Highlight Relevant Skills and Experience

Emphasize your technical skills in epitaxial reactor operation, troubleshooting, and process development.

- Quantify your experience in operating and maintaining epitaxial reactors.

- Provide specific examples of troubleshooting and maintenance procedures you have performed.

3. Showcase Problem-Solving Abilities

Interviews will likely ask about your problem-solving capabilities in a technical setting.

- Prepare examples of challenges you have faced in operating epitaxial reactors and how you resolved them.

- Describe a situation where you identified a process problem and implemented a solution to improve reactor performance.

4. Demonstrate Teamwork and Communication Skills

Epitaxial Reactor Technicians work as part of a team and need strong communication skills.

- Discuss your experience collaborating with other team members to achieve common goals.

- Provide examples of clear and effective communication in technical discussions and documentation.

5. Practice and Prepare Questions

Practice answering common interview questions. Prepare questions for the interviewer to demonstrate your interest and engagement.

- Practice the STAR method (Situation, Task, Action, Result) for answering behavioral questions.

- Prepare questions about the company’s epitaxial reactor technology, process development initiatives, and career growth opportunities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Epitaxial Reactor Technician interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.