Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Equipment Maintenance Superintendent position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

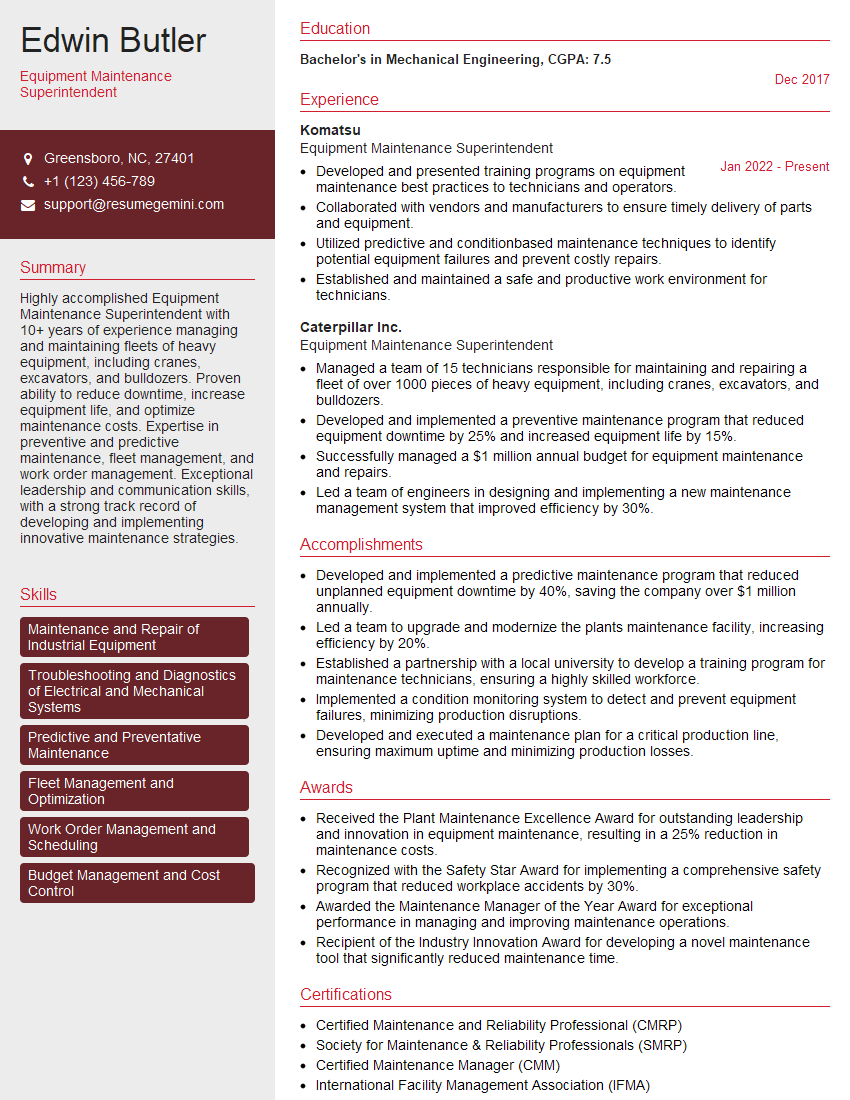

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Equipment Maintenance Superintendent

1. What are the key performance indicators (KPIs) that you would track to measure the effectiveness of your maintenance program?

The following KPIs are commonly used to measure the effectiveness of a maintenance program:

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

- Equipment availability

- Maintenance cost

- Overall equipment effectiveness (OEE)

2. How would you develop and implement a preventative maintenance (PM) plan for a complex piece of equipment?

Planning and Preparation

- Identify the equipment to be maintained

- Gather data on the equipment’s history, operating conditions, and manufacturer’s recommendations

- Determine the appropriate PM tasks and intervals

Implementation

- Develop a PM schedule

- Assign responsibilities for PM tasks

- Train personnel on PM procedures

- Implement a system for tracking PM completion

3. What are the different types of maintenance strategies and when would you recommend using each one?

- Reactive maintenance: Performed only when equipment fails, this strategy is typically used for low-risk, low-cost equipment.

- Preventative maintenance: Performed on a regular basis to prevent failures, this strategy is typically used for critical equipment or equipment that is subject to high wear and tear.

- Predictive maintenance: Uses data analysis to predict when equipment is likely to fail, this strategy allows for maintenance to be performed before a failure occurs.

- Condition-based maintenance: Monitors equipment condition and performs maintenance when necessary, this strategy is typically used for complex equipment or equipment that is difficult to inspect.

4. What are your thoughts on the use of computerized maintenance management systems (CMMS)?

- CMMS can improve maintenance efficiency and effectiveness by automating tasks, tracking data, and providing insights.

- CMMS can help to reduce maintenance costs by optimizing maintenance schedules and identifying areas for improvement.

- CMMS can improve safety by providing maintenance personnel with access to up-to-date information on equipment condition and maintenance procedures.

5. What is your experience with managing a team of maintenance technicians?

- Outlined my experience in leading and motivating a team of maintenance technicians.

- Described my approach to performance management and employee development.

- Shared examples of how I have successfully resolved conflicts and built a positive team culture.

6. What are the latest trends in equipment maintenance and how are you staying up-to-date with these trends?

- Discussed the growing use of predictive maintenance and condition-based maintenance.

- Described the benefits of using CMMS and other software tools to improve maintenance efficiency.

- Explained how I stay up-to-date with the latest trends by attending industry conferences, reading trade publications, and participating in online forums.

7. How would you handle a situation where you have limited resources and need to prioritize maintenance tasks?

- Outlined my process for prioritizing maintenance tasks based on criticality, risk, and cost.

- Described how I would communicate with stakeholders to explain my decisions and secure additional resources if necessary.

- Shared examples of how I have successfully prioritized maintenance tasks in the past.

8. What are the most important safety considerations for equipment maintenance?

- Outlined the importance of following lockout/tagout procedures.

- Described the need to wear appropriate personal protective equipment (PPE).

- Discussed the importance of maintaining a clean and organized work area.

- Shared examples of how I have ensured the safety of my team and myself during maintenance operations.

9. What are your strengths and weaknesses as an Equipment Maintenance Superintendent?

Strengths:

- Strong technical skills and knowledge of equipment maintenance.

- Excellent leadership and communication skills.

- Proven ability to manage a team and prioritize tasks.

Weaknesses:

- Limited experience with some of the latest maintenance technologies.

- Sometimes I can be too detail-oriented.

10. Why are you interested in this position and why should we hire you?

- Expressed my interest in the company and the position.

- Highlighted my qualifications and experience that make me a good fit for the role.

- Emphasized my commitment to safety and my passion for equipment maintenance.

- Concluded by expressing my confidence that I have the skills and experience to be a successful Equipment Maintenance Superintendent.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Equipment Maintenance Superintendent.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Equipment Maintenance Superintendent‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Equipment Maintenance Superintendent plays a pivotal role in ensuring the seamless operation of equipment and machinery within the organization. Their key responsibilities include:

1. Equipment Management and Maintenance

Overseeing the maintenance and upkeep of all equipment, machinery, and facilities within the organization, ensuring optimal functionality and safety.

- Developing and implementing comprehensive preventive maintenance plans and schedules to minimize downtime and extend equipment lifespan.

- Directing and supervising a team of maintenance technicians, allocating tasks and monitoring performance to achieve maintenance goals.

2. Equipment Inspection and Repair

Conducting regular inspections and assessments of equipment to identify potential issues and prevent breakdowns.

- Diagnosing and troubleshooting equipment problems accurately and efficiently, implementing appropriate repair strategies.

- Coordinating and overseeing major repairs and overhauls, ensuring adherence to safety protocols and industry best practices.

3. Inventory Management and Procurement

Managing spare parts inventory, ensuring adequate stock levels to minimize downtime during repairs.

- Collaborating with suppliers to procure necessary parts and materials, negotiating favorable terms and ensuring timely delivery.

- Implementing inventory control systems to track spare parts usage, minimize waste, and optimize purchasing strategies.

4. Budget Management and Cost Control

Preparing and managing a maintenance budget, allocating funds effectively to ensure adequate equipment upkeep.

- Monitoring maintenance costs, identifying areas for cost optimization, and implementing cost-effective maintenance practices.

- Collaborating with finance and operations teams to ensure budget alignment and financial accountability.

Interview Preparation Tips

To ace the interview for the Equipment Maintenance Superintendent position, candidates should focus on demonstrating their technical expertise, leadership skills, and commitment to operational excellence. Here are some interview preparation tips:

1. Research the Company and Industry

Thoroughly research the organization’s industry, products, and services. Understand their mission, values, and unique challenges.

2. Highlight Relevant Experience and Skills

Emphasize your experience in equipment maintenance, project management, and budget control. Quantify your accomplishments and provide specific examples of your contributions to previous organizations.

3. Prepare for Technical Questions

Expect technical questions about maintenance strategies, equipment troubleshooting, and preventative maintenance techniques. Be prepared to discuss your knowledge of maintenance software and technologies.

4. Demonstrate Leadership and Communication

Highlight your ability to lead and motivate a team, allocate responsibilities effectively, and communicate clearly with cross-functional stakeholders.

5. Show Passion and Enthusiasm

Convey your passion for equipment maintenance and your commitment to ensuring the smooth operation of the organization’s equipment.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Equipment Maintenance Superintendent interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.