Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Equipment Superintendent position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

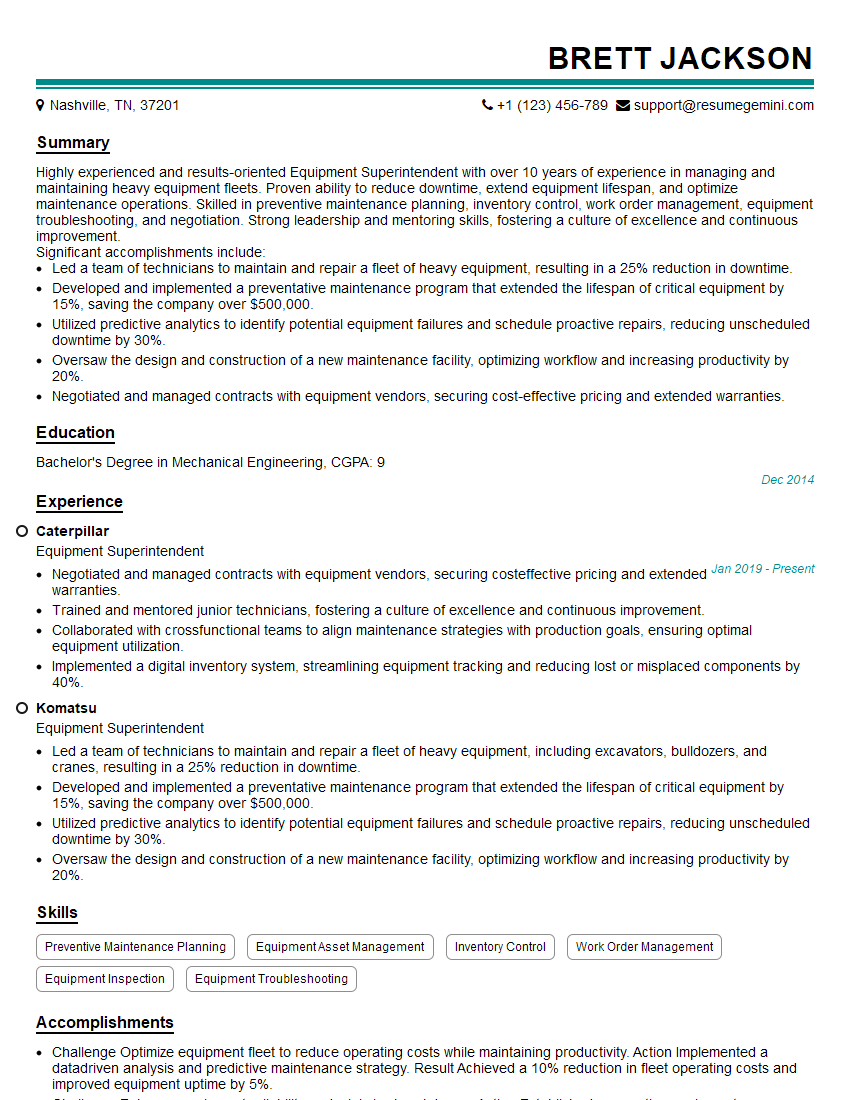

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Equipment Superintendent

1. How do you maintain and inspect heavy equipment to ensure optimal performance and minimize downtime?

- Regularly conduct inspections of all equipment, including visual checks, fluid level checks, and functional testing.

- Maintain a detailed maintenance log to track inspections, repairs, and replacements.

- Establish preventative maintenance schedules based on manufacturer recommendations and historical data

2. Describe your experience in managing a team of mechanics and technicians.

Team Management

- Provide clear instructions and training to ensure tasks are completed efficiently and safely.

- Motivate and encourage team members to work effectively by fostering a positive and collaborative work environment.

Resource Allocation

- Allocate resources effectively to maximize productivity and minimize downtime.

- Coordinate with other departments to ensure timely access to necessary parts and materials.

3. How do you stay up-to-date with the latest advances in equipment technology and best practices?

- Attend industry conferences and webinars to learn about new technologies and trends.

- Read trade publications and technical journals to stay informed about best practices.

- Collaborate with equipment manufacturers and other industry professionals to exchange knowledge and experiences.

4. Describe a situation where you successfully resolved a major equipment breakdown.

- Diagnosed the problem quickly and accurately using troubleshooting techniques.

- Determined the necessary repairs and coordinated with the maintenance team to implement the solution efficiently.

- Ensured that the repaired equipment met performance specifications and safety standards.

5. How do you prioritize equipment maintenance and repairs to optimize resource allocation and minimize disruption to operations?

- Establish clear maintenance priorities based on equipment criticality and potential impact on operations.

- Use a computerized maintenance management system (CMMS) to track equipment maintenance history and identify potential issues.

- Collaborate with operations and other departments to understand their maintenance needs and schedule repairs accordingly.

6. What is your approach to safety management in an equipment maintenance environment?

- Establish and enforce strict safety protocols for all maintenance activities.

- Provide comprehensive safety training to all employees and ensure they follow proper procedures.

- Regularly inspect equipment and work areas to identify and eliminate potential hazards.

7. How do you ensure that equipment maintenance records are accurate, complete, and easily accessible?

- Implement a comprehensive maintenance record-keeping system that includes both historical and real-time data.

- Use a CMMS or other software to automate record-keeping and ensure accuracy.

- Establish clear procedures for data entry and maintenance to prevent errors and omissions.

8. Describe your experience in managing capital equipment budgets and justifying equipment purchases.

- Forecast equipment needs and develop realistic budgets based on historical maintenance costs and industry trends.

- Conduct thorough cost-benefit analyses to justify equipment purchases and upgrades.

- Collaborate with management to secure funding for necessary equipment investments.

9. How do you stay informed about industry best practices and emerging technologies in equipment maintenance?

- Attend industry conferences, workshops, and trade shows to network with peers and learn about new technologies.

- Subscribe to industry publications and online forums to stay up-to-date on trends and best practices.

- Collaborate with equipment manufacturers and vendors to gain insights into advanced technologies and maintenance strategies.

10. What motivates you to succeed as an Equipment Superintendent?

- A passion for equipment maintenance and a desire to ensure optimal performance.

- The challenge of managing complex equipment systems and resolving technical issues.

- The opportunity to lead a team of skilled technicians and contribute to the overall success of the organization.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Equipment Superintendent.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Equipment Superintendent‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Equipment Superintendent is responsible for the effective management and maintenance of a diverse fleet of equipment and machinery used in heavy industry operations.

1. Equipment Management

Supervise and ensure the proper operation, maintenance, and repair of all heavy equipment, machinery, and vehicles.

- Establish and enforce maintenance schedules and procedures.

- Conduct regular inspections to identify potential issues.

2. Fleet Optimization

Analyze equipment usage and performance to identify opportunities for improvement.

- Implement strategies to maximize equipment utilization and reduce downtime.

- Monitor fuel consumption and implement measures to enhance fuel efficiency.

3. Safety and Compliance

Ensure compliance with all safety regulations and protocols.

- Conduct safety inspections and provide training to staff.

- Investigate incidents and implement corrective measures.

4. Workforce Management

Recruit, hire, train, and supervise a team of equipment technicians and maintenance personnel.

- Provide clear guidance and set performance expectations.

- Foster a positive and productive work environment.

5. Budget and Resource Allocation

Manage the equipment department’s budget and resources.

- Forecast equipment needs and secure funding for necessary upgrades.

- Negotiate contracts with vendors for parts and services.

Interview Tips

To prepare for an interview for an Equipment Superintendent position, consider the following tips:

1. Research the Company

Familiarize yourself with the company’s operations, industry, and recent news.

- Visit the company’s website and social media pages.

- Read articles and press releases about the company.

2. Highlight Your Technical Skills

Emphasize your expertise in equipment maintenance and repair, including your knowledge of specific equipment types and industry standards.

- Quantify your experience by providing specific examples of successful projects.

- Discuss your understanding of current trends and technologies in equipment management.

3. Showcase Your Leadership Abilities

Provide evidence of your ability to lead and motivate a team.

- Describe a time when you successfully implemented a new maintenance procedure.

- Explain how you handle conflicts and build consensus among team members.

4. Demonstrate Your Safety Awareness

Emphasize your commitment to safety and compliance.

- Explain your approach to conducting safety inspections and training.

- Discuss your experience in investigating incidents and implementing corrective actions.

5. Prepare Questions

Thoughtfully prepare questions to ask the interviewer. This will demonstrate your interest in the position.

- Inquire about the specific challenges and opportunities the company faces.

- Ask about the company’s plans for future equipment investments.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Equipment Superintendent interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!