Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Equipment Validation Specialist position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

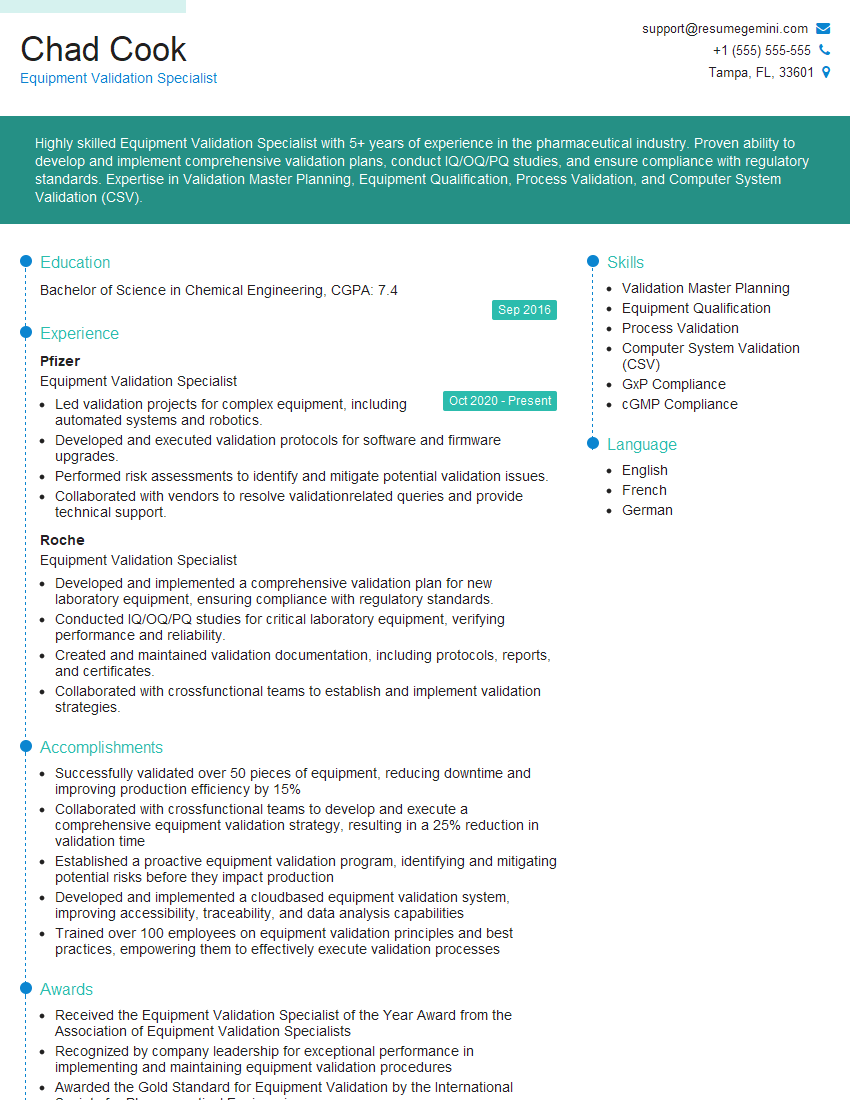

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Equipment Validation Specialist

1. What is the purpose of Equipment Validation?

The purpose of Equipment Validation is to provide documented evidence that equipment used in manufacturing processes consistently produces products that meet predetermined specifications and quality standards.

- Ensure equipment operates as intended

- Meet regulatory compliance requirements

- Reduce risks and improve product quality

2. Describe the key steps involved in Equipment Validation.

Pre-Validation

- Define user requirements

- Develop validation plan

- Gather equipment documentation

Validation

- Conduct Installation Qualification (IQ)

- Perform Operational Qualification (OQ)

- Execute Performance Qualification (PQ)

Post-Validation

- Monitor and maintain equipment

- Document changes and updates

3. Explain the difference between Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ).

- IQ: Verifies that equipment is installed correctly and meets specifications

- OQ: Demonstrates that equipment operates as intended under normal operating conditions

- PQ: Ensures that equipment consistently produces products that meet predetermined quality standards

4. What are the different types of Validation Documentation required for Equipment Validation?

- Validation Plan

- IQ/OQ/PQ Protocols

- Test Results

- Deviation Logs

- Equipment Maintenance Records

5. What are the regulatory requirements for Equipment Validation?

- FDA 21 CFR Part 210/211

- ICH Q7

- ISO 13485

- GMP Guidelines

6. How do you determine the appropriate acceptance criteria for Equipment Validation?

- Based on user requirements and product specifications

- Industry standards and regulations

- Historical data and process knowledge

7. What are the common challenges in Equipment Validation and how do you address them?

- Inadequate documentation: Gather all necessary documentation and ensure it is up-to-date

- Insufficient testing: Define clear and comprehensive test protocols to ensure thorough validation

- Lack of resources: Plan effectively and allocate resources efficiently

8. How do you manage changes to validated equipment?

- Document changes and assess their impact

- Conduct additional testing and validation as necessary

- Update validation documentation and master records

9. What are the best practices for continuous monitoring and maintenance of validated equipment?

- Establish regular calibration and maintenance schedules

- Monitor equipment performance and document any deviations

- Implement preventive maintenance measures to minimize downtime

10. How do you stay up-to-date with industry standards and regulatory requirements for Equipment Validation?

- Attend industry conferences and seminars

- Read technical literature and journals

- Collaborate with industry professionals and regulatory agencies

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Equipment Validation Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Equipment Validation Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Equipment Validation Specialists are responsible for ensuring that equipment used in the production of medical devices meets the required standards and specifications.

1. Develop and execute validation protocols

This involves identifying the specific tests that need to be performed to verify the equipment’s performance, and writing detailed procedures for conducting those tests.

- Create test plans and procedures for equipment validation

- Execute validation protocols and document results

2. Conduct validation testing

This involves running the tests according to the developed protocols, and recording and analyzing the results.

- Operate and maintain validation equipment

- Monitor and record test data

3. Prepare validation reports

This involves summarizing the test results and providing an interpretation of their significance. These reports are used to demonstrate that the equipment meets the required standards and specifications.

- Analyze and interpret test results

- Write validation reports and summaries

4. Maintain validation records

This involves keeping all of the documentation related to the validation process, including test plans, procedures, results, and reports.

- Maintain validation records and documentation

- Respond to regulatory inquiries and audits

Interview Preparation Tips

To ace an interview for an Equipment Validation Specialist position, it is important to prepare effectively. Here are some tips:

1. Research the company and the position

This will help you understand the company’s culture, values, and specific requirements for the position. You can research the company’s website, LinkedIn page, and industry publications.

- Visit the company’s website to learn about their mission, values, and products/services.

- Check the company’s LinkedIn page to see what employees are saying about the company culture and work environment.

- Read industry publications to stay up-to-date on the latest trends and developments in the field.

2. Practice answering common interview questions

There are several common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” You can prepare for these questions by practicing your answers in advance.

- Prepare for behavioral questions by using the STAR method (Situation, Task, Action, Result).

- Practice answering technical questions related to equipment validation.

- Be prepared to discuss your experience with validation software and methodologies.

3. Highlight your relevant skills and experience

Make sure to emphasize your skills and experience that are relevant to the position. This includes your experience with equipment validation, your knowledge of industry regulations, and your ability to work independently.

- Quantify your accomplishments using specific metrics.

- Use keywords from the job description in your resume and interview answers.

- Be prepared to provide examples of your work.

4. Be professional and enthusiastic

First impressions matter, so it is important to dress professionally and be on time for your interview. You should also be enthusiastic and positive about the position. This will show the interviewer that you are interested in the job and that you are confident in your abilities.

- Dress professionally and arrive on time for your interview.

- Be polite and respectful to everyone you meet, including the receptionist and other employees.

- Maintain eye contact and speak clearly.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Equipment Validation Specialist interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!