Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Etched Circuit Processor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

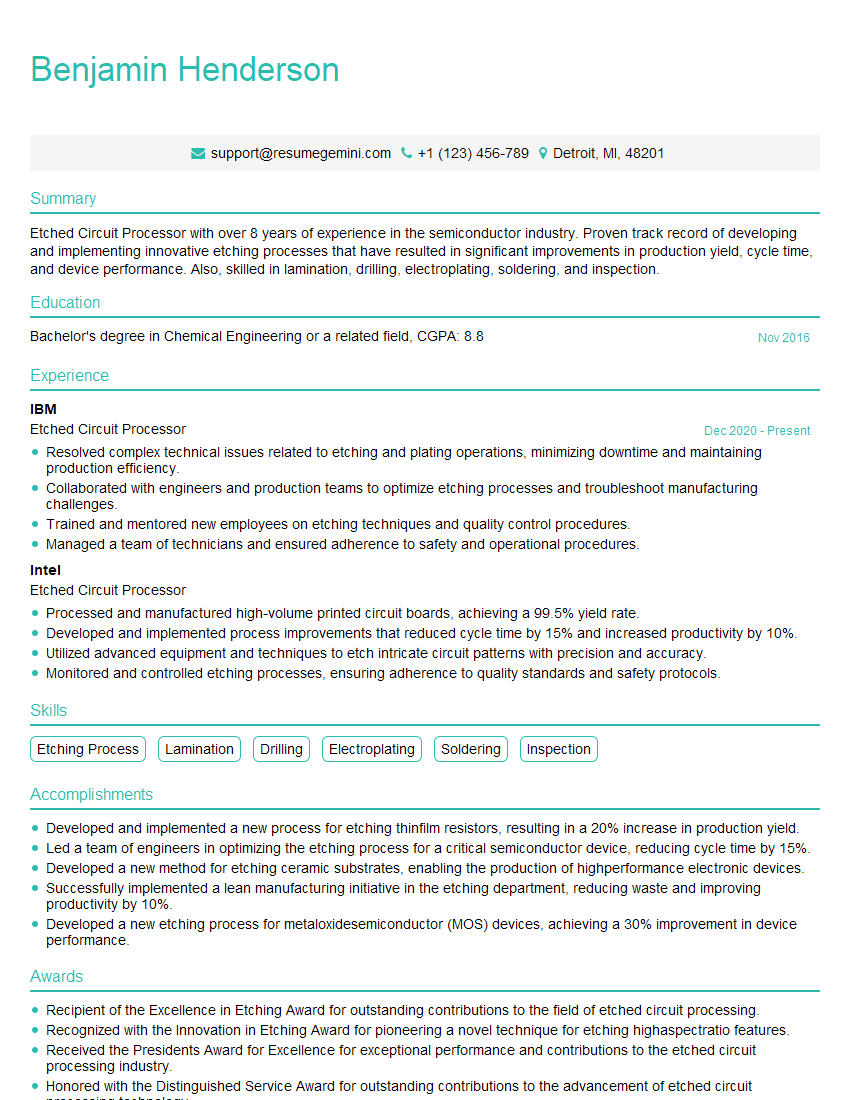

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Etched Circuit Processor

1. What are the key steps involved in the etching process of an etched circuit processor?

- Preparation of the Copper-Clad Laminate: Cleaning and roughening the surface of the copper-clad laminate to enhance adhesion.

- Application of Photoresist: Coating the laminate with a light-sensitive photoresist and exposing it to ultraviolet light through a photomask.

- Development of the Photoresist: Removing unexposed photoresist areas using a developer solution, creating a protective layer over the desired circuit pattern.

- Etching: Submerging the laminate in an etching solution (e.g., ferric chloride) to dissolve exposed copper areas, leaving only the desired circuit pattern.

- Stripping of Photoresist: Removing the remaining photoresist layer using an appropriate solvent.

2. Describe the different types of etching techniques used in etched circuit processor fabrication.

Wet Etching:

- Involves immersing the laminate in an etching solution that dissolves the unwanted copper.

- Can be isotropic (etches in all directions) or anisotropic (etches in a specific direction).

Dry Etching:

- Uses plasma or reactive gases to remove material.

- Offers better control over etching depth and sidewall profiles.

3. What are the critical factors that affect the quality and yield of etched circuits?

- Photoresist Adhesion: Proper cleaning and preparation ensure strong adhesion.

- Exposure and Development: Accurate exposure and development times are crucial for precise circuit patterns.

- Etching Solution Composition and Temperature: Etching rate and uniformity depend on solution composition and temperature.

- Substrate Material: Different laminates have varying etching characteristics.

- Process Equipment: Regular maintenance and calibration ensure consistent results.

4. How do you optimize the etching process for specific circuit designs?

- Selecting the Right Etching Technique: Wet or dry etching based on desired precision and profile.

- Etching Solution Parameters: Concentration, temperature, and agitation to control etch rate and selectivity.

- Exposure and Development Optimization: Adjusting times to achieve desired pattern resolution.

- Post-Etching Treatment: Additional steps like annealing or plating to improve circuit performance.

5. What quality control measures are implemented to ensure the accuracy and reliability of etched circuits?

- Visual Inspection: Examining circuits for defects, shorts, or opens.

- Electrical Testing: Continuity and resistance measurements to verify circuit functionality.

- Microscopic Analysis: Assessing circuit dimensions, sidewall profiles, and surface roughness.

- Statistical Process Control: Monitoring key process parameters to identify and correct potential issues.

6. Describe the role of etching in the fabrication of multi-layer printed circuit boards (PCBs).

- Interconnect Formation: Etching creates conductive traces on each layer, connecting components.

- Layer Stacking: Multiple layers are aligned and laminated together, forming a multi-layer PCB.

- Drilling and Plating: Vias are drilled and plated to connect layers electrically.

7. Discuss the emerging trends and advancements in etched circuit processing technology.

- High-Resolution Lithography: Techniques like photoresist jetting for precise pattern formation.

- Plasma Etching: Advanced plasma processes for anisotropic etching and improved sidewall control.

- Additive Manufacturing: 3D printing techniques for prototyping and small-scale production.

8. How do you stay up-to-date with the latest developments in etched circuit fabrication?

- Attending Conferences and Workshops: Industry events for knowledge sharing.

- Reading Technical Journals and Papers: Research and publications on advancements.

- Online Resources and Forums: Websites and discussion groups for information exchange.

9. What are the key safety considerations in the etching process?

- Chemical Handling: Safe handling and disposal of etching solutions.

- Ventilation: Adequate ventilation to prevent exposure to chemical fumes.

- Personal Protective Equipment: Gloves, goggles, and appropriate clothing.

- Waste Management: Proper disposal of etching waste according to environmental regulations.

10. How do you troubleshoot common issues that arise during etching?

- Under-etching or Over-etching: Adjust etching time or solution parameters.

- Sidewall Roughness: Optimize plasma etching conditions or post-etching treatments.

- Copper Shorts: Examine photoresist coverage and adhesion, optimize etching solution composition.

- Etching Stop Failures: Ensure proper resist removal and substrate preparation.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Etched Circuit Processor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Etched Circuit Processor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Etched Circuit Processors are responsible for the production of high-quality circuit boards, typically working in electronics manufacturing environments. Their tasks require attention to detail, operational knowledge of circuit board manufacturing, and proficiency in operating equipment.

1. Circuit Board Fabrication

Operate and monitor etching, plating, and laminating machines to produce and assemble circuit boards according to design specifications.

- Configure and set up machines with the appropriate parameters.

- Troubleshoot and resolve any technical issues that arise during production.

2. Process Control

Monitor and maintain process parameters within specified tolerances to ensure the quality of circuit boards.

- Conduct quality checks at various stages of production.

- Calibrate and maintain equipment to ensure accuracy and precision.

3. Problem Solving

Identify and resolve any problems that may arise during the circuit board production process.

- Analyze and investigate errors to determine root causes.

- Implement corrective actions to prevent recurring issues.

4. Safety Compliance

Adhere to all safety regulations and guidelines in the manufacturing environment.

- Use personal protective equipment (PPE) and follow established safety protocols.

- Report any unsafe conditions or practices to supervisors.

Interview Tips

To ace an interview for an Etched Circuit Processor position, it is essential to prepare thoroughly and demonstrate your understanding of the role and the industry.

1. Research the Company and Position

Research the company and the specific position you are applying for. This will help you understand their values, culture, and the requirements of the role.

- Visit the company’s website and social media pages.

- Read industry publications and news articles to gain insights into the latest trends and technologies.

2. Practice Your Answers to Common Questions

Prepare for common interview questions, such as “Tell me about your experience in circuit board manufacturing” or “How do you handle quality control issues?”.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers.

- Provide specific examples from your previous work experience to demonstrate your skills and abilities.

3. Showcase Your Technical Expertise

Emphasize your technical skills and knowledge in circuit board manufacturing. Discuss your proficiency in operating etching, plating, and laminating machines.

- Mention any certifications or training programs you have completed.

- Provide examples of projects where you have successfully applied your technical skills.

4. Highlight Your Problem-Solving Abilities

Problem-solving is a crucial skill for Etched Circuit Processors. Highlight your ability to identify and resolve issues that arise during production.

- Describe a situation where you successfully identified and resolved a technical issue.

- Explain the steps you took to analyze the problem and implement a solution.

5. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the position and the company. Prepare questions related to the company’s future plans, industry trends, or opportunities for professional development.

- Avoid asking generic questions that can be easily answered online.

- Use the opportunity to gain additional insights and show that you are genuinely interested in the role.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Etched Circuit Processor, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Etched Circuit Processor positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.