Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Ethanol Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

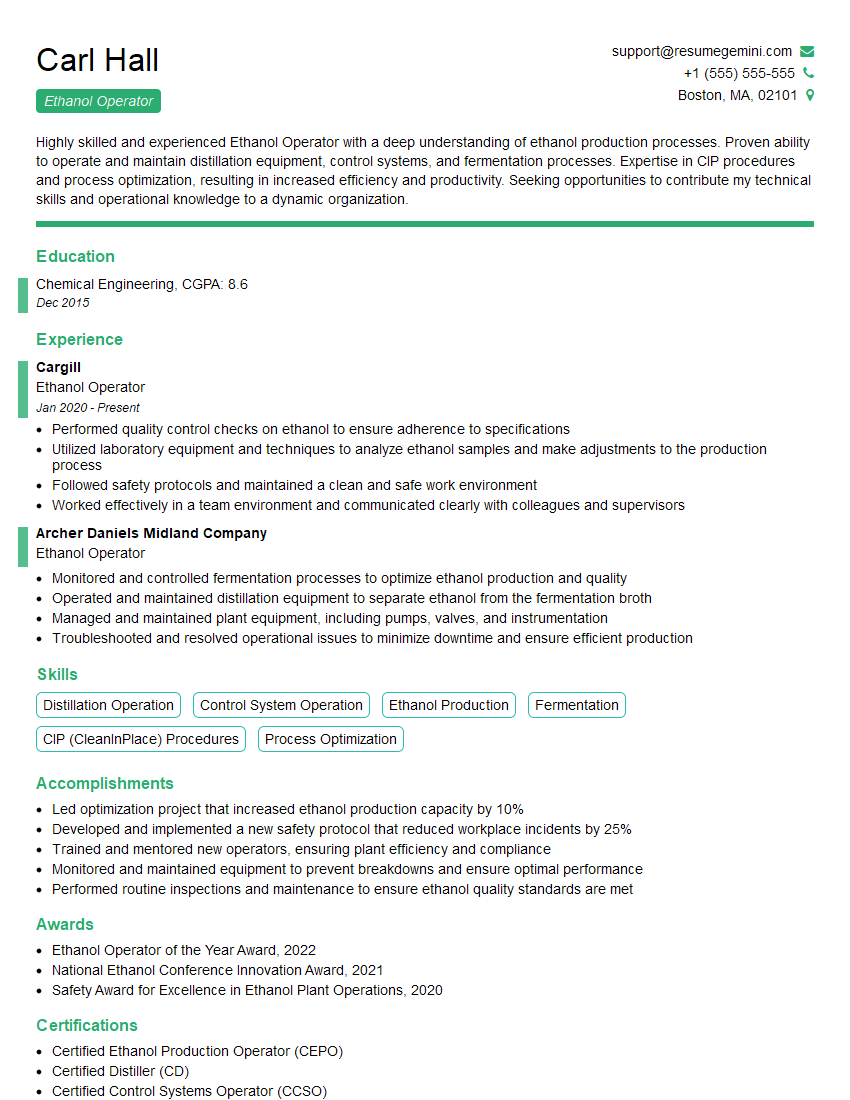

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Ethanol Operator

1. Explain the process of ethanol production in detail.

The process of ethanol production involves several steps:

- Feedstock Preparation: Grain (corn, wheat, etc.) is milled and mixed with water to create a mash.

- Fermentation: Yeast is added to the mash, converting sugars into ethanol and carbon dioxide.

- Distillation: The fermented mash is distilled to separate ethanol from other components.

- Dehydration: The distilled ethanol contains water and is further dehydrated using molecular sieves to achieve the desired ethanol concentration.

2. Describe the different types of fermentation used in ethanol production.

Batch Fermentation

- Yeast is added to a closed vessel containing the mash.

- Fermentation occurs until the yeast consumes all the sugars.

Continuous Fermentation

- Fresh mash is continuously added to the fermentation vessel.

- Fermented mash is continuously removed, maintaining a constant yeast population.

3. What are the key parameters to monitor during ethanol fermentation?

Critical parameters to monitor during fermentation include:

- Temperature

- pH

- Yeast viability

- Sugar concentration

- Ethanol concentration

4. How do you optimize ethanol yield in the fermentation process?

Optimizing ethanol yield involves:

- Controlling fermentation temperature and pH

- Maintaining optimal yeast health and viability

- Ensuring sufficient nutrient availability

- Managing sugar concentration to prevent inhibition

5. Describe the distillation process used to separate ethanol from the fermentation broth.

Distillation is a process that separates liquids based on their boiling points:

- The fermented broth is heated, and ethanol, having a lower boiling point, vaporizes first.

- The ethanol vapor is condensed and collected as the distillate.

- Multiple distillation columns may be used to increase ethanol concentration.

6. What safety precautions should be followed when working in an ethanol production facility?

Safety precautions in an ethanol facility include:

- Wearing appropriate personal protective equipment (PPE)

- Handling flammable materials with care

- Following lockout/tagout procedures

- Maintaining a clean and organized work area

- Understanding and adhering to safety protocols

7. How do you troubleshoot common problems encountered in ethanol production?

Common problems and troubleshooting steps include:

- Low ethanol yield: Optimize fermentation conditions, check yeast health, and ensure nutrient availability.

- Contamination: Identify the source of contamination and implement appropriate sanitation measures.

- Equipment malfunctions: Conduct regular maintenance, inspect equipment regularly, and follow manufacturer’s instructions.

8. What is the importance of quality control in ethanol production?

Quality control ensures that ethanol meets specifications and is safe for use:

- Testing ethanol purity and concentration

- Monitoring for contaminants and impurities

- Ensuring compliance with regulations and industry standards

9. Describe the environmental considerations in ethanol production.

Environmental considerations in ethanol production include:

- Wastewater treatment: Managing wastewater generated from fermentation and other processes.

- Greenhouse gas emissions: Minimizing emissions through efficient energy use and renewable energy sources.

- Sustainability: Utilizing sustainable feedstocks and implementing practices that reduce environmental impact.

10. What are the future trends and advancements in ethanol production?

Future trends include:

- Development of advanced fermentation technologies

- Exploration of alternative feedstocks (e.g., algae, biomass)

- Integration with renewable energy sources

- Research on genetic engineering for improved yeast strains

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Ethanol Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Ethanol Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Ethanol Operator, you will have a range of key responsibilities that will contribute to the safe and efficient operation of the ethanol production facility.

1. Process Monitoring and Control

You will be responsible for monitoring and controlling the various processes involved in ethanol production, ensuring that they are operating within optimal parameters. This includes:}

- Monitoring process variables such as temperature, pressure, and flow rates.

- Making adjustments to process parameters to maintain desired conditions.

- Identifying and troubleshooting process deviations to prevent equipment damage or production losses.

2. Equipment Operation and Maintenance

You will be responsible for operating and maintaining the equipment used in ethanol production, including:

- Cookers, fermenters, distillation columns, and other process equipment.

- Performing routine maintenance tasks such as cleaning, lubricating, and calibrating equipment.

- Identifying and reporting equipment malfunctions or breakdowns for timely repairs.

3. Production Optimization

You will be involved in analyzing production data to identify areas for improvement and optimizing the efficiency of the ethanol production process. This may include:

- Evaluating production yields and identifying opportunities for increased output.

- Implementing process modifications or operational changes to improve efficiency.

- Collaborating with engineers and maintenance personnel to optimize equipment performance.

4. Quality Control

You will be responsible for ensuring the quality of the ethanol produced by the facility, by performing:

- Sampling and testing ethanol products to ensure compliance with specifications.

- Monitoring process parameters to identify potential quality issues.

- Implementing corrective actions to address quality deviations.

Interview Tips

Preparing for an Ethanol Operator interview requires a combination of technical knowledge, industry understanding, and interpersonal skills. Here are some tips to help you ace the interview:

1. Research the Ethanol Industry

Familiarize yourself with the ethanol production process, the different types of equipment used, and the current market trends. This knowledge will demonstrate your interest in the industry and your understanding of the role.

2. Highlight Relevant Experience

Emphasize your previous experience in operating and maintaining industrial equipment, particularly in the chemical or manufacturing sector. Showcase your ability to monitor processes, troubleshoot problems, and implement improvements.

3. Practice Process Control Scenarios

Be prepared to discuss your approach to process monitoring and control. Provide examples of how you have identified and resolved process deviations in previous roles.

4. Understand Ethanol Quality Standards

Demonstrate your knowledge of ethanol quality standards and your experience in performing quality control tests. Explain how you would ensure the quality of ethanol produced by the facility.

5. Show Your Safety Consciousness

Ethanol production involves hazardous materials and processes. Highlight your understanding of safety protocols and your commitment to adhering to all safety guidelines in the workplace.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Ethanol Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!