Are you gearing up for an interview for a Excavating Machine Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Excavating Machine Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

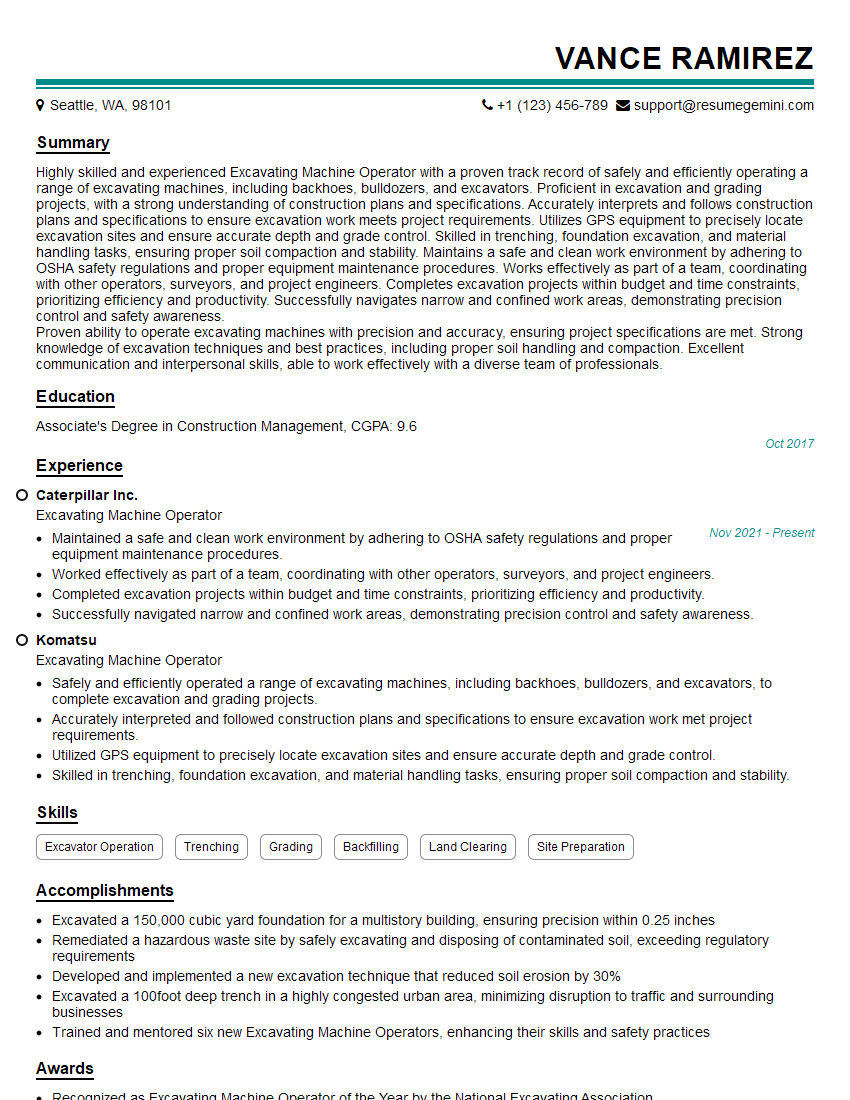

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Excavating Machine Operator

1. What are the key components of an excavating machine and what is the function of each component?

- Hydraulic system: Provides the power to move the machine’s components and attachments.

- Engine: Generates the power for the hydraulic system.

- Undercarriage: Provides stability and mobility to the machine.

- Boom and arm: Allow the machine to reach and dig at various angles.

- Bucket: Used for excavating and transporting material.

- Cab: Provides a safe and comfortable operating environment for the operator.

2. How do you determine the correct bucket size for a specific excavation task?

Factors to consider:

- Material properties: Hardness, density, and moisture content.

- Excavation depth and volume: The larger the volume and depth, the larger the bucket needed.

- Machine capabilities: Maximum bucket size and lifting capacity.

- Efficiency and productivity: Balancing excavation speed with material handling capacity.

Example:

- For digging hard and compact soil, a smaller bucket with sharp teeth is recommended to minimize resistance.

- For large-volume excavations in soft soil, a larger bucket can increase efficiency.

3. Explain the steps involved in planning and executing a trench excavation.

- Pre-excavation planning: Determine excavation depth, width, length, location of utilities and obstacles.

- Site preparation: Clear vegetation, mark excavation area, establish access points.

- Excavation execution: Dig the trench using the appropriate bucket and excavation techniques.

- Trench protection: Implement measures such as shoring and bracing to prevent cave-ins.

- Material handling: Remove excavated material and dispose of it properly.

- Backfilling and compaction: Fill the trench with suitable material and compact it to ensure stability.

4. Describe the safety precautions you take when operating an excavating machine.

- Pre-operation checks: Inspect the machine, attachments, and safety features.

- Work area assessment: Identify hazards, overhead obstacles, and utility lines.

- Proper positioning: Stay within the machine’s stability limits and maintain a safe distance from slopes and excavations.

- Clear communication: Use hand signals or radios to coordinate with colleagues and avoid collisions.

- Emergency procedures: Be familiar with emergency shutdown procedures and escape routes.

5. How do you maintain an excavating machine to ensure optimal performance and longevity?

- Regular inspections and servicing: Follow manufacturer’s maintenance schedule.

- Lubrication: Grease and oil moving parts as recommended.

- Hydraulic system maintenance: Change hydraulic fluid, filters, and hoses regularly.

- Attachment inspections: Check for wear and damage on buckets and other attachments.

- Record keeping: Maintain a logbook to document inspections, repairs, and maintenance.

6. Explain how you handle unexpected situations or emergencies while operating an excavating machine.

- Assess the situation: Quickly evaluate the risks and potential hazards.

- Communicate with colleagues: Alert them to the situation and seek assistance if needed.

- Follow emergency procedures: Implement established shutdown and escape protocols.

- Isolate the machine: Shut off power and secure the bucket.

- Report the incident: Inform the supervisor and relevant authorities promptly.

7. Describe your experience in using different types of attachments for excavating machines.

- Hydraulic hammer: For breaking concrete, rocks, and frozen ground.

- Auger: For drilling holes for foundations, utilities, and geotechnical investigations.

- Grapple: For handling and moving large or irregularly shaped objects.

- Ripper: For loosening hard soil or rock formations.

- Compactor: For compacting soil and gravel in trenches and backfills.

8. Explain how you use excavation techniques to minimize soil erosion and protect the environment.

- Phased excavation: Excavate in sections to reduce exposed soil surfaces.

- Erosion control measures: Install erosion barriers, silt fences, and sedimentation ponds.

- Vegetation preservation: Retain existing vegetation to stabilize slopes and prevent erosion.

- Controlled water management: Divert water away from excavation areas and prevent sediment runoff.

- Proper backfilling and compaction: Restore the soil structure and prevent erosion.

9. How do you interpret site plans and blueprints to guide your excavation work?

- Identify excavation dimensions: Depth, width, and length.

- Locate utility lines and obstacles: Avoid damaging underground infrastructure.

- Understand soil conditions: Determine the appropriate excavation techniques.

- Plan access and egress: Ensure safe and efficient movement of equipment and materials.

- Follow safety protocols: Adhere to guidelines and regulations.

10. How do you collaborate with other construction professionals on site?

- Communicate effectively: Share information and coordinate activities.

- Respect roles and responsibilities: Understand your place in the project team.

- Seek feedback and support: Collaborate to achieve the best results.

- Resolve conflicts professionally: Work together to find solutions and maintain a positive work environment.

- Maintain a positive attitude: Contribute to a collaborative and productive team atmosphere.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Excavating Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Excavating Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As an Excavating Machine Operator, you will be responsible for operating a variety of excavating equipment to perform tasks such as digging trenches, foundations, and holes.

1. Excavation and Grading

Use excavating machines to dig trenches, foundations, and holes

- Interpret blueprints and construction plans to determine excavation requirements

- Excavate according to specified depths, widths, and slopes

2. Equipment Maintenance and Inspection

Perform regular maintenance and inspections on excavating equipment

- Check fluid levels, filters, and other components

- Identify and report any mechanical issues or damage

3. Site Preparation and Safety

Prepare work areas and ensure adherence to safety protocols

- Clear work areas of debris and obstructions

- Wear appropriate safety gear and follow safety procedures

- Establish barricades and warning signs around excavation sites

4. Material Handling

Handle excavated materials and dispose of them properly

- Load excavated materials into dump trucks or other vehicles

- Transport materials to designated disposal areas

- Ensure proper disposal of hazardous materials

Interview Tips

1. Research the Company and Industry

Research the company’s activities, projects, and industry trends.

- Demonstrates your interest and preparedness

- Enables you to ask insightful questions

2. Practice Your Answers

Prepare answers for common interview questions related to your skills and experience.

- Improves your confidence and delivery

- Gives you time to reflect on your experiences and accomplishments

3. Highlight Relevant Experience and Skills

Focus on highlighting your skills that are most relevant to the job requirements.

- Quantify your accomplishments with specific examples

- Emphasize your ability to operate and maintain excavating equipment

4. Show Enthusiasm and Passion

Convey your enthusiasm for the role and the construction industry.

- Express your interest in the company and their projects

- Share your eagerness to learn and contribute

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Excavating Machine Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!